Composite wear-resistant plate for chute and preparation method thereof

A technology of wear-resistant plate and metal composite plate, which is applied in the field of chute, can solve the problems of impact resistance, wear resistance and service life that cannot meet the maintenance period of equipment, and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Select a 12mm thick 304 stainless steel plate and cut it into a stainless steel metal substrate with a size of 300*300mm; 3

[0030] Select a glass-ceramic plate of wollastonite system with a thickness of 15 mm, and cut it into a glass-ceramic plate 2 with a size of 300*300 mm;

[0031] Select 0.36mm~5mm thick PVB film, PU film or EVA film, and cut it into 300*300mm size;

[0032] Stack together in the order of glass-ceramic plate / film / metal substrate;

[0033] Use nylon film or vacuum bag to vacuumize the above three-layer structure, and put it into the autoclave according to the lamination process of the corresponding film, and heat up and increase the pressure;

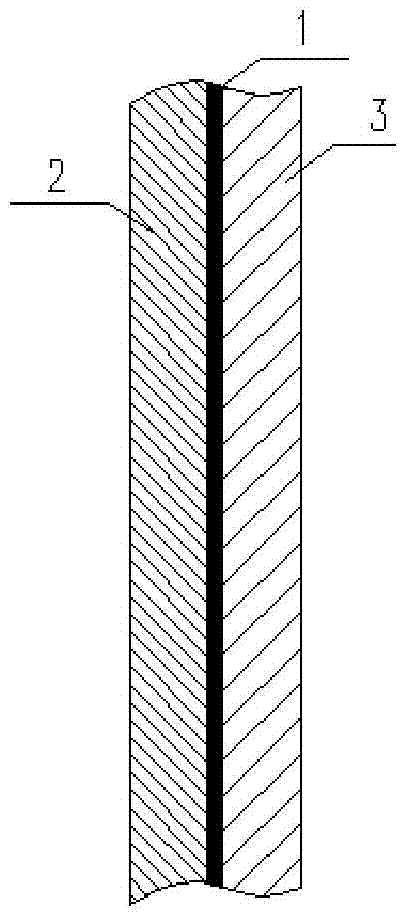

[0034] After cooling out of the kettle, the glass-ceramic plate and the metal substrate are bonded together by film melting, and the obtained glass-ceramic-metal composite plate is the composite wear-resistant plate for the chute. The structure of gained composite wear-resistant plate sees figure 1 . fig...

Embodiment 2

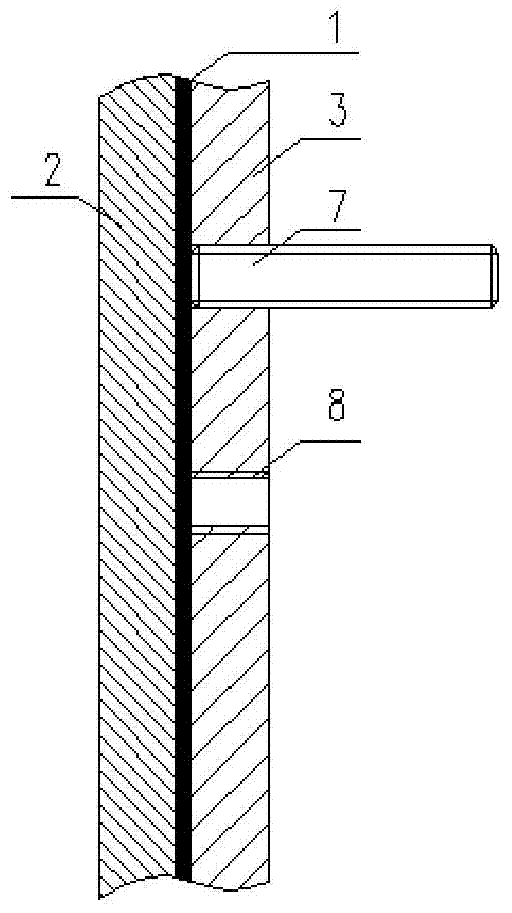

[0036] The difference between this embodiment and the first embodiment is that the glass-ceramic-metal composite plate has threaded holes for setting connecting bolts. Therefore, on the basis of Embodiment 1, first process the φ8mm threaded hole 8 at the corresponding position of the metal substrate of the stainless steel plate according to the design, and then laminate the film in the order of glass-ceramic plate / film / metal substrate. The structure of gained composite wear-resistant plate sees figure 2 . The connecting bolts in this embodiment are stud bolts 7, and one end of the stud bolt 7 is fixedly connected to the metal base plate 3 through the threaded hole 8 to realize assembly with the composite wear-resistant plate. Of course, the composite wear-resistant plate can also be fixed to the installation wall by passing through the installation wall and connecting the threaded hole 8 on the metal base plate 3 during installation.

Embodiment 3

[0038] Select ordinary carbon steel plates with a thickness of 12mm and cut them into metal substrates with a size of 300*300mm;

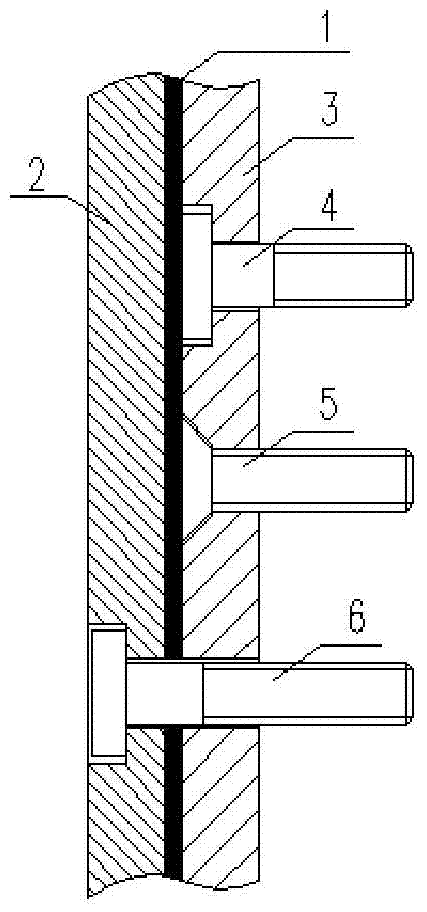

[0039] Process the φ8mm through hole at the corresponding position of the metal substrate according to the design drawing, and process it into a counterbore on the steel plate according to the size of the nut (bolt head) of the φ6-7mm stepped bolt; see image 3 The assembly positions of the bolts 4 and 5 of the two types. Such as image 3 As mentioned above, the shape and size of the counterbore match the shape and size of the nut of the connecting bolt selected. Generally, the cross-section of the nut and its matching counterbore should be non-circular to facilitate the installation operation. The section of the counterbore matched with the bolt 4 is stepped, and the section of the counterbore matched with the bolt 5 is trapezoidal.

[0040] Fill the counterbore with epoxy resin or unsaturated polyester mud, insert the supporting connecting bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com