Micro-bridge structure of micro radiation detector and array thereof

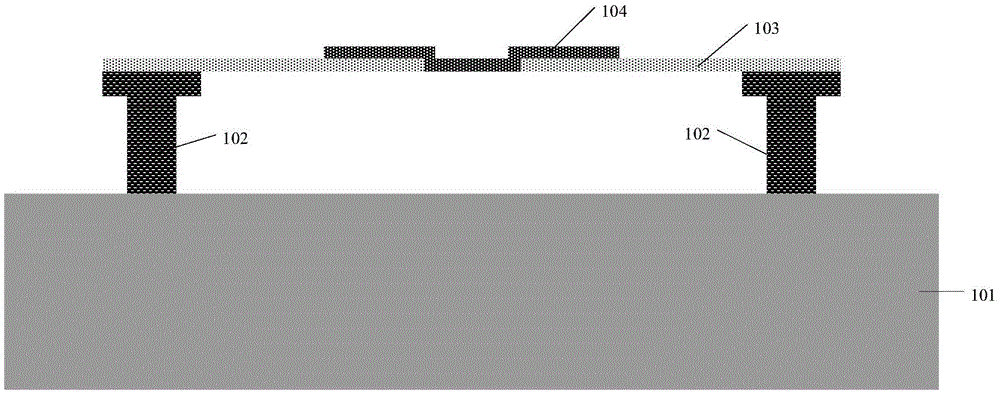

A radiation detector and micro-bridge structure technology, applied in the field of micro-electromechanical systems, can solve problems such as fracture, difficult balance of the overall structure of the micro-radiation detector, and warping of pixels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

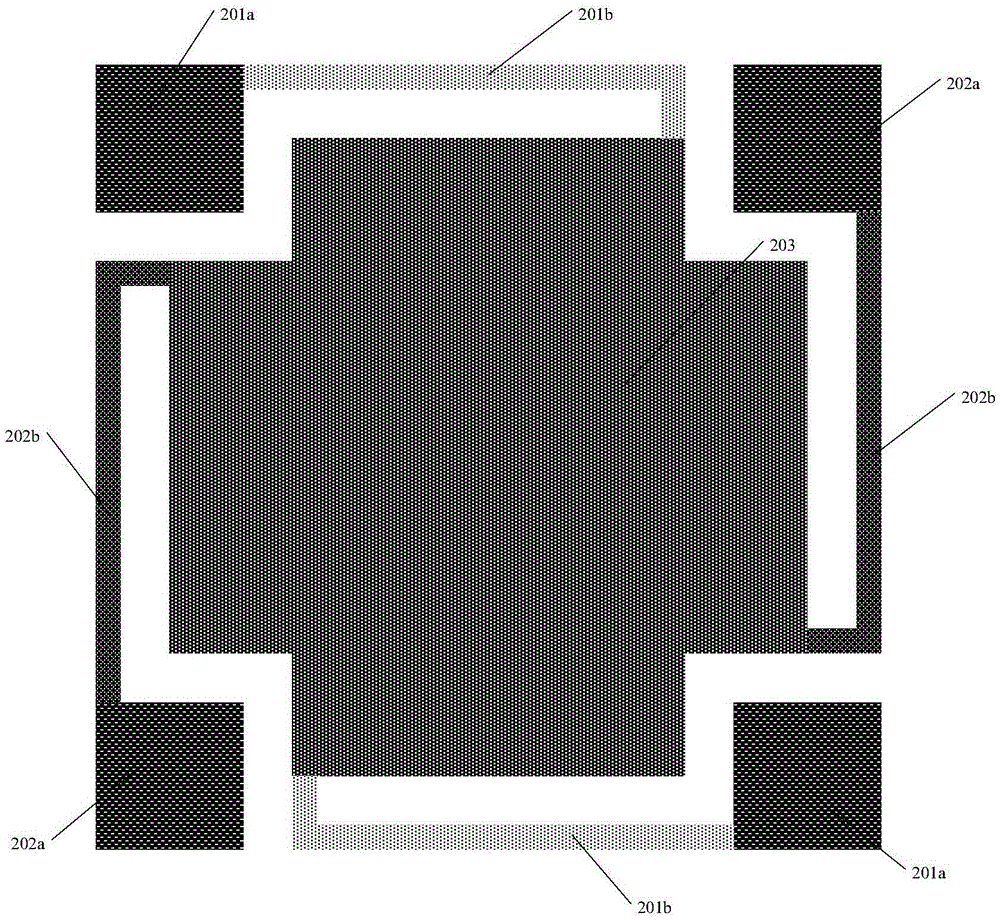

[0039] Please refer to Figure 2a, which is a schematic plan view of the micro-bridge structure of the micro-radiation detector according to Embodiment 1 of the present invention. Among them, the bridge deck 203 is suspended on the semiconductor substrate, and the bridge deck 203 is symmetrical along the X-axis direction and the Y-axis direction, and has a square symmetrical structure. There is a square gap at its four corners, and the four support columns 102 are respectively Set at the position of the square notch. In this embodiment, the first group of beams 201b and the second group of beams 202b are drawn along the four corners of the bridge deck 203, wherein the two opposite first group beams 201b only provide mechanical connection, and the two oppositely arranged second Beam set 202b provides both mechanical and electrical connections. Preferably, in this embodiment, both the first group of beams 201b and the second group of beams 202b have one bend, and in other embo...

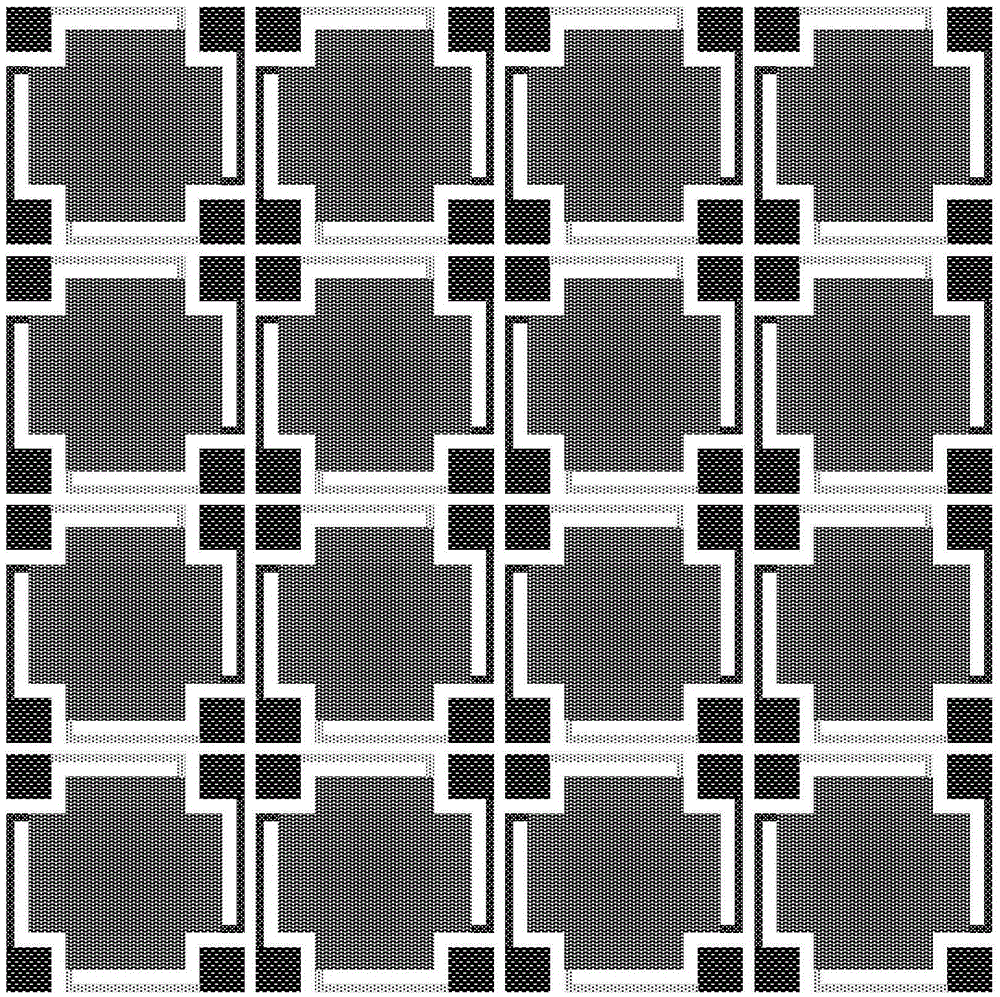

Embodiment 2

[0042] Please refer to Figure 3a , which is a schematic plan view of the micro-bridge structure of the micro-radiation detector according to the second preferred embodiment of the present invention. Similar to Embodiment 1, it has a bridge deck 203, a first pair of support columns 201a and a second pair of support columns 202a arranged diagonally, and a first group of beams 201b and a second group of beams 202b connected thereto. The support column 201a and the first group of beams 201b only provide mechanical connection, and the second pair of support columns 202a and the second group of beams 202b provide both mechanical connection and electrical connection; the difference from the first embodiment is that the connection between the beam and the support column The position close to the inner side of the support column, that is, the side close to the bridge deck 203 , preferably, in this embodiment, the distance between the outer edge of the beam and the midpoint of the cros...

Embodiment 3

[0046] Please refer to Figure 4a , which is a schematic plan view of the micro-bridge structure of the micro-radiation detector according to the third preferred embodiment of the present invention. Similar to Embodiment 1, it has a bridge deck 203, a first pair of support columns 201a and a second pair of support columns 202a arranged diagonally, and a first group of beams 201b and a second group of beams 202b connected thereto, 201a and 201b Only provide mechanical connection, the first pair of support columns 201a and the first group of beams 201b only provide mechanical connection, the second pair of support columns 202a and the second group of beams 202b provide both mechanical connection and electrical connection; the difference is that only mechanical The supporting pillars 201a have a larger cross-section, while the supporting pillars 202a that provide both mechanical support and electrical connection have a smaller cross-section. In addition, the connection between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com