Zero-discharge on-line treatment process for preparing deionized water from copper sulphate electroplating wastewater

A technology for electroplating wastewater and treatment process, applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. , to achieve the effect of zero-emission recycling, prolonging the regeneration cycle and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

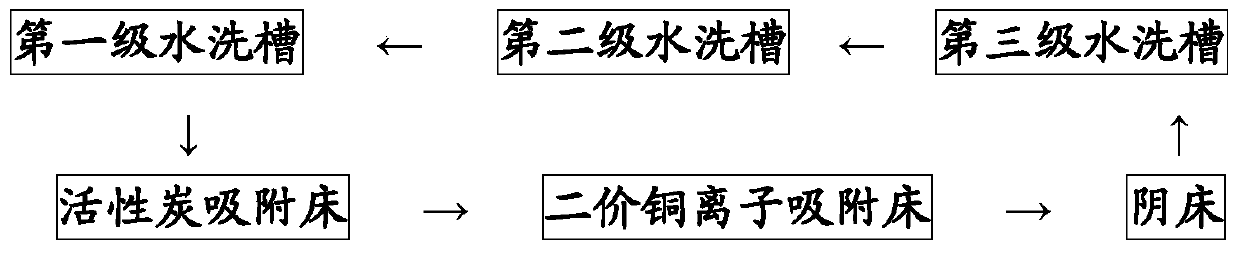

[0055] Example 1: Zero-discharge online treatment process for copper sulfate electroplating wastewater

[0056] The process flow is as follows:

[0057] 1. The process flow of a copper sulfate electroplating unit for a PCB printed circuit board is: acid copper electroplating→first-stage water washing→second-stage water washing→third-stage water washing→subsequent treatment. The water flow direction of the electroplating unit is: pure water storage tank→third-level washing tank→second-level washing tank→first-level washing tank→comprehensive wastewater treatment tank.

[0058] 2. The treatment process of acid copper electroplating wastewater is:

[0059] Acid copper electroplating wastewater→activated carbon adsorption bed→divalent copper ion adsorption bed→yin bed→deionized water

[0060] Among them, the activated carbon adsorption bed is equipped with activated carbon, which is used to absorb the light agent organic matter in the electroplating wastewater. The volume of the...

Embodiment 2

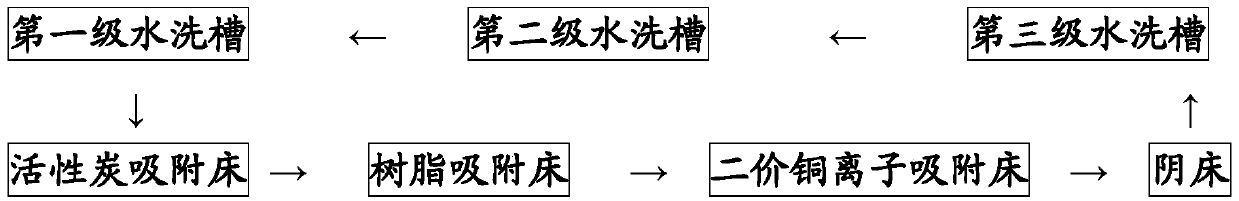

[0066] Example 2 Copper Sulfate Electroplating Wastewater Zero Discharge Online Treatment Process

[0067] The process flow is as follows:

[0068] 1. The process flow of a copper sulfate electroplating unit for a PCB printed circuit board is: acid copper electroplating→first-stage water washing→second-stage water washing→third-stage water washing→subsequent treatment. The water flow direction of the electroplating unit is: pure water storage tank→third-level washing tank→second-level washing tank→first-level washing tank→comprehensive wastewater treatment tank.

[0069] 2. The treatment process of acid copper electroplating wastewater is:

[0070] Considering that acid copper electroplating wastewater also contains a small amount of sodium polydisulfide dipropane sulfonate, which is difficult to be adsorbed by activated carbon, we added an ion exchange resin adsorption bed to the above acid copper electroplating wastewater treatment process to adsorb polydisulfide Organic s...

Embodiment 3

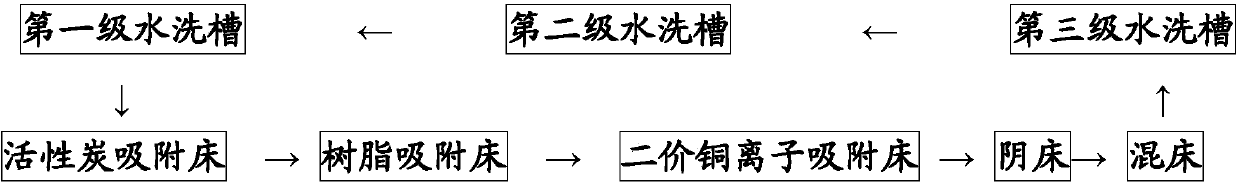

[0077] Example 3: Zero-discharge online treatment process for copper sulfate electroplating wastewater

[0078] The process flow is as follows:

[0079] 1. The process flow of a copper sulfate electroplating unit for a PCB printed circuit board is: acid copper electroplating→first-stage water washing→second-stage water washing→third-stage water washing→subsequent treatment. The water flow direction of the electroplating unit is: pure water machine deionized water→third-stage washing tank→second-stage washing tank→first-stage washing tank→comprehensive wastewater treatment tank.

[0080] 2. The treatment process of acid copper electroplating wastewater is:

[0081] In order to further improve the quality of produced water and prolong the regeneration cycle of the resin, we added a mixed bed on the basis of the wastewater treatment process described in step 2 of Example 2.

[0082] The wastewater treatment process is as follows: acid copper electroplating wastewater→activated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Critical value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com