Method for preparing low-molecular chondroitin sulfate through electron beam irradiation

A technology of chondroitin sulfate and electron beam irradiation, which is applied in the field of preparation of low-molecular chondroitin sulfate by electron beam irradiation, which can solve problems such as large amount of alcohol, difficulty in controlling molecular weight degradation, unstable functional activity of enzyme preparation products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

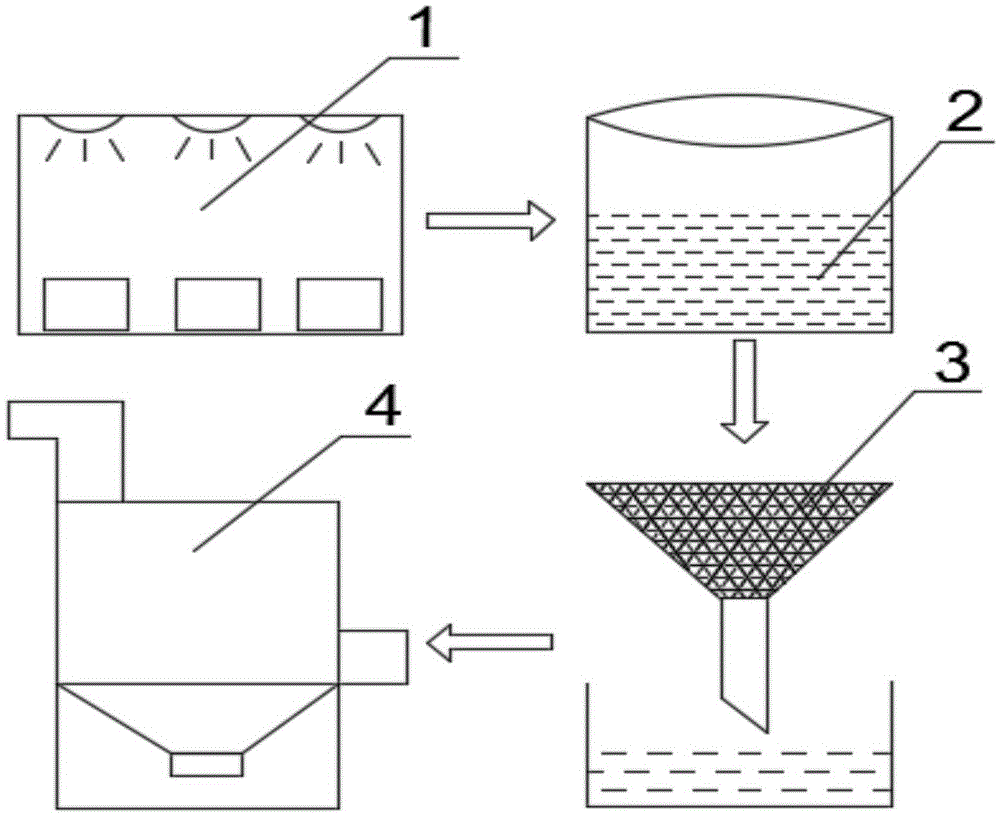

Method used

Image

Examples

Embodiment Construction

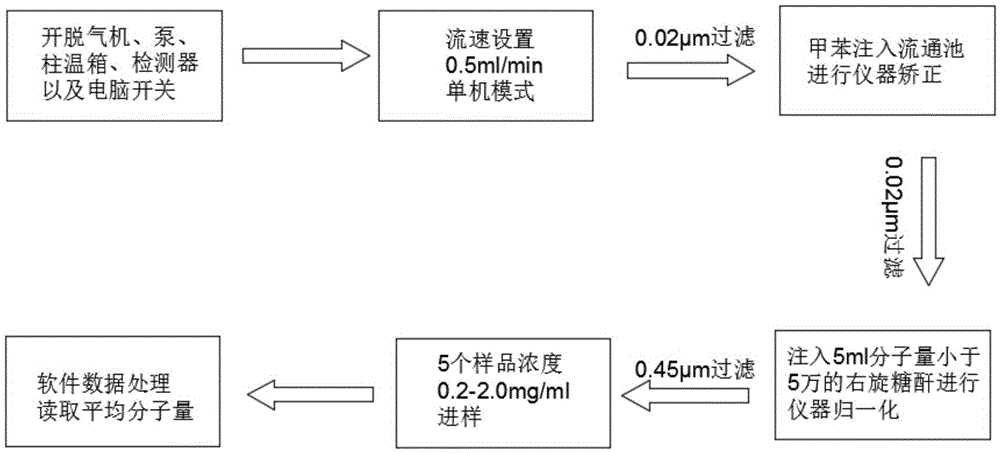

[0020] 60 grams of chondroitin sulfate dry powder raw materials selected, its weight average molecular weight (Mw) measured by an eighteen-angle laser light scattering instrument is 3.5 * 10 4 Da. At room temperature of 24°C, the dry powder raw materials are directly irradiated with electron beams generated by energy electron accelerators in the industry. The energy of the electron beam is 2.5MeV, and the irradiation dose of the chondroitin sulfate dry powder raw material is 220KGy. After irradiation, the sample was configured into a 12% aqueous solution, and the ultrafiltration membrane with a cut-off of 5000Da was used to remove small molecular impurities and concentrated. The purified concentrated solution was powdered by spray drying mechanism, the inlet temperature was 110°C, and the outlet temperature was 60°C. A total of 54.1 grams of chondroitin sulfate dry powder product was collected, and the product yield was 90.2%. Its weight-average molecular weight (Mw) measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com