Preparation method of organic-inorganic hybrid porous integral material

A monolithic material and hybridization technology, which is applied in the field of preparation of organic-inorganic hybrid porous monolithic materials, can solve problems such as not showing the potential of high-efficiency separation and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

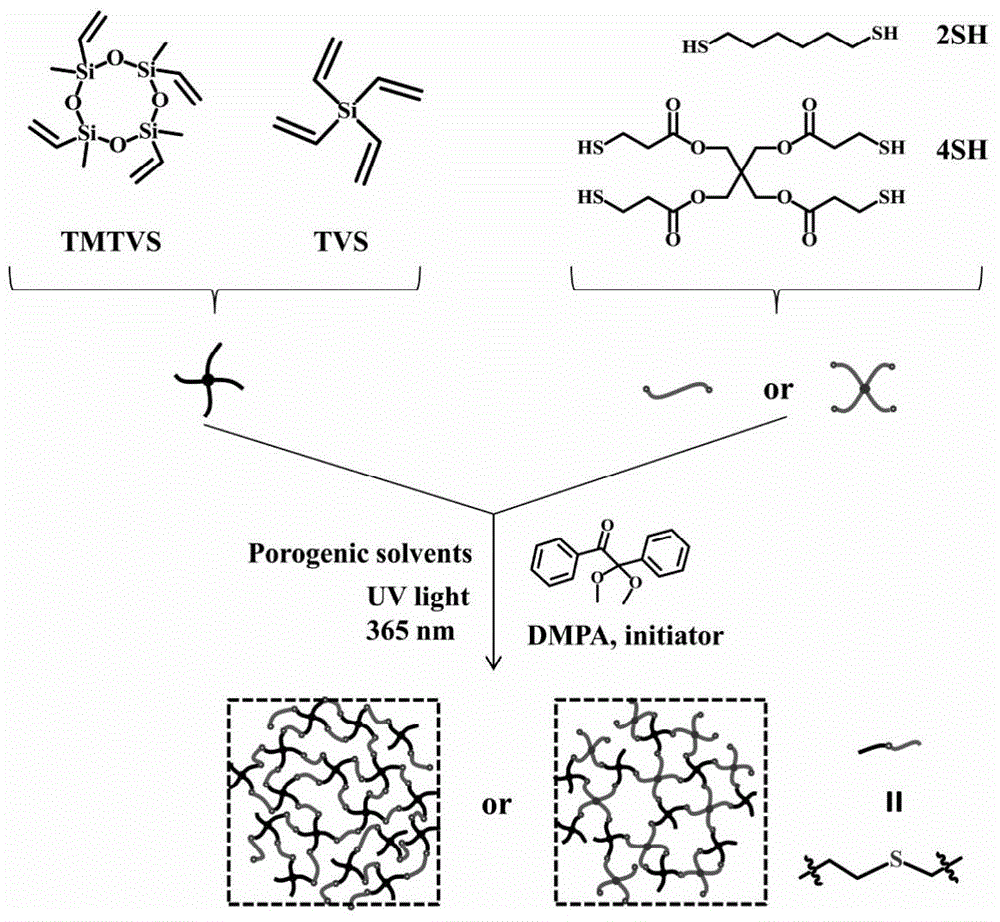

Method used

Image

Examples

Embodiment 1

[0027] 1. Add 25.0mg of TMTVS reagent to the UV transparent glass bottle.

[0028] 2. Add 21.3 mg of 2SH to the above-mentioned UV transparent glass bottle.

[0029] 3. Add 80 μL of diethylene glycol diethyl ether and 100 μL of n-propanol into the above-mentioned ultraviolet transparent glass bottle.

[0030] 4. Add 0.1 mg of photoinitiator DMPA to the above-mentioned ultraviolet transparent glass bottle, and ultrasonicate the above-mentioned ultraviolet transparent glass bottle for 1 min to mix the components therein evenly, and remove the dissolved oxygen dissolved therein.

[0031]5. Use a syringe to introduce the mixed solution obtained in step 4 into a 75 μm (inner diameter) UV transparent capillary tube that has been pre-activated with vinyltrimethoxysilane, then seal both ends of the capillary tube with silica gel, and then put the remaining mixing liquid in a UV transparent glass bottle with airtight seal.

[0032] 6. Place the UV transparent capillary and UV transpa...

Embodiment 2

[0035] 1. Add 15.5 mg of TVS reagent to the UV transparent glass bottle.

[0036] 2. Add 26.8 mg of 2SH to the above-mentioned UV transparent glass bottle.

[0037] 3. Add 170 μL of diethylene glycol diethyl ether and 10 μL of n-propanol into the above-mentioned ultraviolet transparent glass bottle.

[0038] 4. Add 0.1 mg of photoinitiator DMPA to the above-mentioned ultraviolet transparent glass bottle, and ultrasonicate the above-mentioned ultraviolet transparent glass bottle for 1 min to mix the components therein evenly, and remove the dissolved oxygen dissolved therein.

[0039] 5. Use a syringe to introduce the mixed solution obtained in step 4 into a 75 μm (inner diameter) UV transparent capillary tube that has been pre-activated with vinyltrimethoxysilane, then seal both ends of the capillary tube with silica gel, and then put the remaining mixing liquid in a UV transparent glass bottle with airtight seal.

[0040] 6. Place the UV transparent capillary and UV transpa...

Embodiment 3

[0043] 1. Add 32.4mg of TMTVS reagent to the UV transparent glass bottle.

[0044] 2. Add 35.0 mg of 4SH to the above-mentioned UV transparent glass bottle.

[0045] 3. Add 100 μL of diethylene glycol diethyl ether and 140 μL of n-propanol into the above-mentioned ultraviolet transparent glass bottle.

[0046] 4. Add 0.1 mg of photoinitiator DMPA to the above-mentioned ultraviolet transparent glass bottle, and ultrasonicate the above-mentioned ultraviolet transparent glass bottle for 1 min to mix the components therein evenly, and remove the dissolved oxygen dissolved therein.

[0047] 5. Use a syringe to introduce the mixed solution obtained in step 4 into a 75 μm (inner diameter) UV transparent capillary tube that has been pre-activated with vinyltrimethoxysilane, then seal both ends of the capillary tube with silica gel, and then put the remaining mixing liquid in a UV transparent glass bottle with airtight seal.

[0048] 6. Place the UV transparent capillary and UV trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com