Preparation method of 6-aminopenicillanic acid

A technology of aminopenicillic acid and penicillin acylase, which is applied in the field of biomedicine, can solve problems such as difficulty in environmental protection, and achieve the effects of improving production efficiency and improving catalytic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Preparation of 6-APA

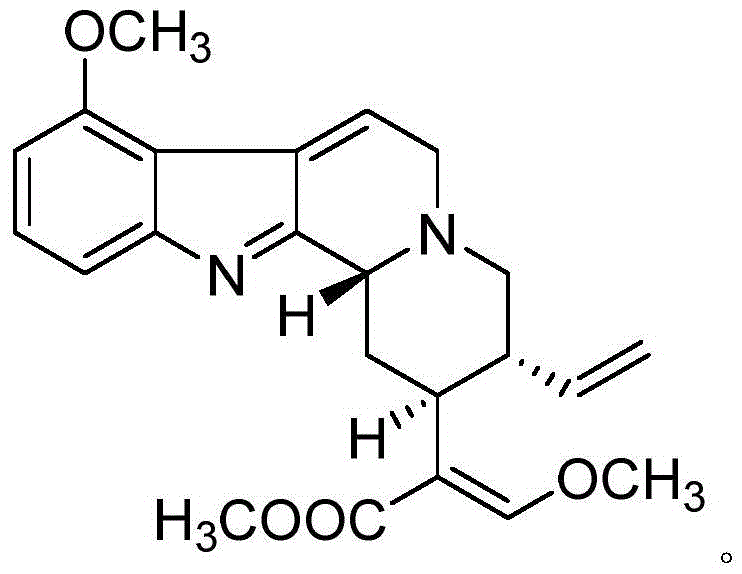

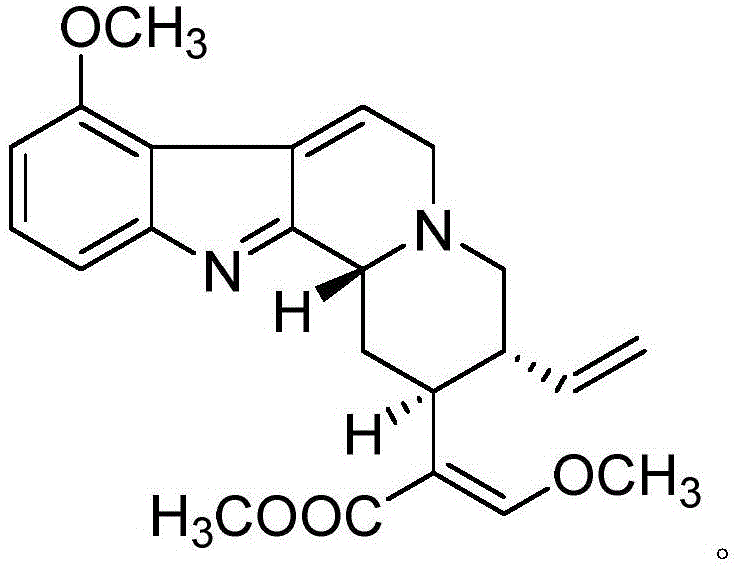

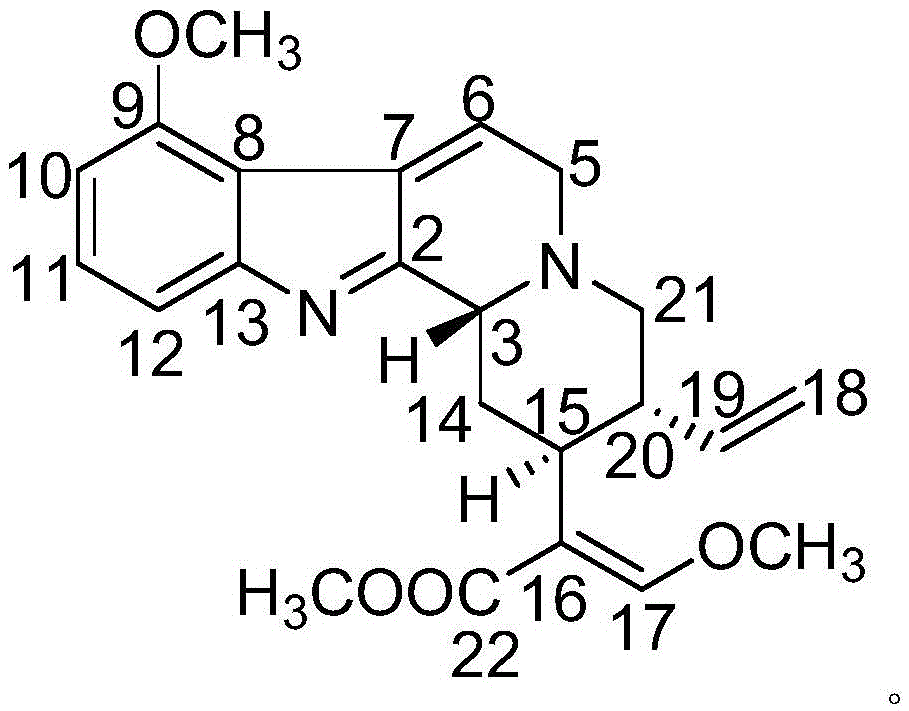

[0030] Place 1,000 mL of penicillin fermentation broth with a concentration of 100,000 U / mL in a stirred reactor with a temperature of 30-34° C. and stir. When the temperature of the fermentation broth reaches 30~34℃, add 60g of penicillin acylase (enzyme activity 120U / g) and 5mg of penicillin acylase activator as shown in the following structure for lysis, and continue to drip during the lysis process Ammonia water with a concentration of 10% maintains the pH value in the reactor at about 7.6. When the pH value in the reactor remains unchanged within 20 minutes after stopping the addition of ammonia water, the reaction ends.

[0031] The mixed liquid after the lysis reaction is passed through a 10-micron filter and a 1-micron filter to remove solid penicillin hyphae. Then the mixed solution is passed through an ultrafilter with a molecular weight cutoff of 30,000 to 50,000 Daltons and an ultrafilter with a molecular weight cutoff of 3000 t...

Embodiment 2

[0038] Example 2: Preparation of 6-APA

[0039] Place 1000 mL of penicillin fermentation broth with a concentration of 100,000 U / mL in a stirred reactor with a temperature controlled at 26-30°C and stir. When the temperature of the fermentation broth reaches 26~30℃, add 60g of penicillin acylase (enzyme activity 120U / g) and 5mg of penicillin acylase activator for lysis, and continuously add 10% concentration during the lysis process Ammonia water, the pH value in the reactor is maintained at 7.0-7.6, when the pH value in the reactor remains unchanged within 20 minutes after the addition of ammonia water is stopped, the reaction ends.

[0040] The mixed liquid after the lysis reaction is passed through a 10-micron filter and a 1-micron filter to remove solid penicillin hyphae. Then the mixed solution is passed through an ultrafilter with a molecular weight cutoff of 30,000 to 50,000 Daltons and an ultrafilter with a molecular weight cutoff of 3000 to 5000 Daltons to remove impuriti...

Embodiment 3

[0045] Example 3: Preparation of 6-APA

[0046] Place 1,000 mL of the penicillin fermentation broth with a concentration of 100,000 U / mL in a stirred reactor whose temperature is controlled at 34-38°C and stir. When the temperature of the fermentation broth reaches 34~38℃, add 60g of penicillin acylase (enzyme activity 120U / g) and 5mg of penicillin acylase activator for lysis, and continuously add 10% concentration during the lysis process Ammonia water, the pH value in the reactor is maintained at 7.6-8.5, when the pH value in the reactor remains unchanged within 20 minutes after the addition of ammonia water is stopped, the reaction ends.

[0047] The mixed liquid after the lysis reaction is passed through a 10-micron filter and a 1-micron filter to remove solid penicillin hyphae. Then the mixed solution is passed through an ultrafilter with a molecular weight cutoff of 30,000 to 50,000 Daltons and an ultrafilter with a molecular weight cutoff of 3000 to 5000 Daltons to remove i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com