A kind of preparation method of railway non-metallic sound-absorbing board

A sound-absorbing panel and non-metallic technology, which is applied in the field of preparation of non-metallic sound-absorbing panels for railways, can solve the problem of unsatisfactory compressive strength and appearance quality of sound-absorbing coefficient products, the steel skeleton is not a whole, and honeycomb is easy to appear Surface and other problems, to achieve the effect of improving appearance quality, good sound absorption effect, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

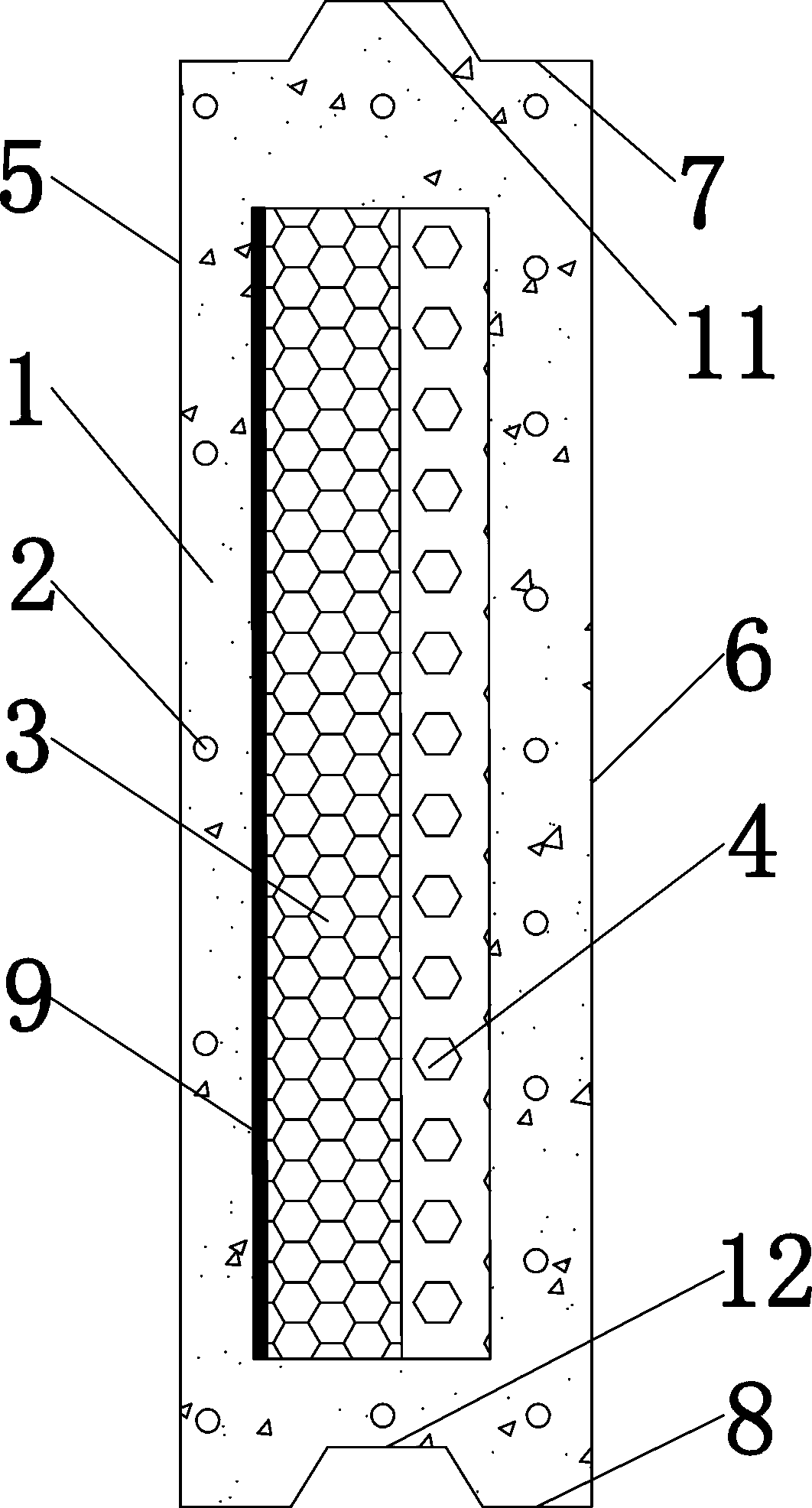

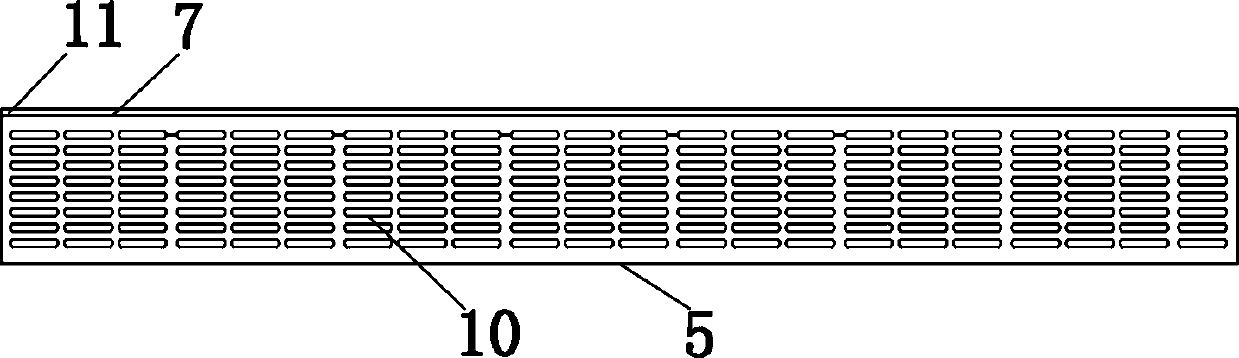

[0037] Embodiment 1: a kind of preparation method of railway non-metallic sound-absorbing board, comprises the following steps:

[0038] Step 1: Install the mold, the bottom support is welded with channel steel and steel plate, the bottom mold is made of EPDM rubber mold, and the side mold is made of aluminum alloy forming mold. Install and adjust the base to be in a horizontal state;

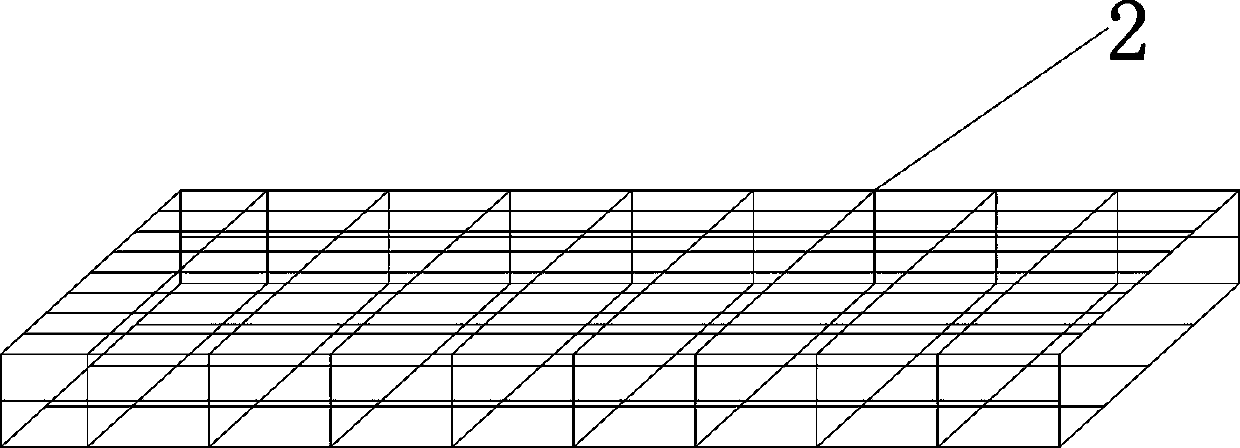

[0039] Step 2: Assembling the reinforcement mesh 2, using φ4 reinforcement to assemble the reinforcement mesh 2 with a cuboid integral connection structure, with 4 transverse reinforcements on the front side, with a spacing of 1000 mm, and 9 horizontal reinforcements on the rear side, with a spacing of 500mm, 2 transverse steel bars are provided on the upper and lower sides with a spacing of 500mm, and 9 longitudinal steel bars perpendicular to the horizontal steel bars are provided on the front, rear, upper and lower sides with a spacing of 500mm. The front side of the steel mesh sheet 2 is i...

Embodiment 2

[0052] Embodiment 2: a kind of preparation method of railway non-metallic sound-absorbing board, comprises the following steps:

[0053] Step 1: Install the mold, the bottom support is welded with channel steel and steel plate, the bottom mold is made of EPDM rubber mold, and the side mold is made of aluminum alloy forming mold. Install and adjust the base to be in a horizontal state;

[0054] Step 2: Assembling the reinforcement mesh sheet 2, using φ4 reinforcement to assemble the reinforcement mesh sheet 2 with a cuboid integral connection structure, with 4-6 transverse reinforcement bars on the front side, with a spacing of 1000 mm, and 11 transverse reinforcement bars on the rear side, The spacing is 500mm, and the upper and lower sides are equipped with 4 transverse reinforcements with a spacing of 500mm. The front, rear, upper and lower sides are equipped with 11 longitudinal reinforcements perpendicular to the horizontal reinforcements, with a spacing of 500mm. , insta...

Embodiment 3

[0067] Embodiment 3: a kind of preparation method of railway non-metallic sound-absorbing board, comprises the following steps:

[0068] Step 1: Install the mold, the bottom support is welded with channel steel and steel plate, the bottom mold is made of EPDM rubber mold, and the side mold is made of aluminum alloy forming mold. Install and adjust the base to be in a horizontal state;

[0069] Step 2: Assembling the steel mesh 2, using φ4 steel bars to assemble the steel mesh 2 with a cuboid integral connection structure, with 5 horizontal steel bars on the front side with a spacing of 1000mm, and 10 horizontal steel bars on the rear side with a spacing of 500mm, 3 horizontal reinforcements are provided on the upper and lower sides with a spacing of 500mm, and 10 longitudinal reinforcements perpendicular to the horizontal reinforcements are provided on the front, rear, upper and lower sides with a spacing of 500mm. The front side of the steel mesh sheet 2 is installed downwar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com