Comprehensive hydraulic power generation system

A hydraulic and hydropower station technology, applied in hydropower, hydropower stations, water conservancy projects, etc., can solve the problems of reducing the working efficiency of hydraulic turbines, not being fully utilized, and affecting the efficiency of the whole machine unit, so as to achieve the maximum utilization rate of water energy The effect of modernization, maximum installed capacity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

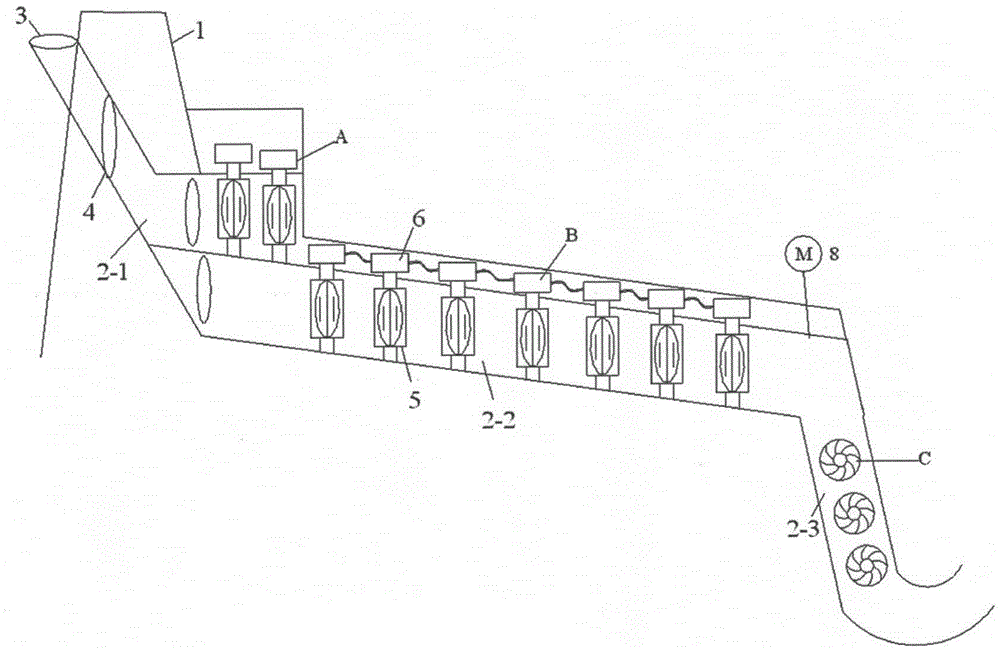

[0034] The integrated hydroelectric power generation system includes units of three power generation modes of "circulation type", "confluence type" and "flow diversion type" arranged in sequence from upstream to downstream. The units of the three power generation modes share a waterway and operate simultaneously to generate electricity. This power generation mode is suitable for ultra-high dams with water storage elevations above 270m and large-flow hydropower stations. Through scientific layout, resources are integrated to ensure that the units of the three different power generation modes can meet their required flow and pressure requirements. The huge hydraulic potential energy can be converted into electrical energy to the greatest extent and with the highest efficiency.

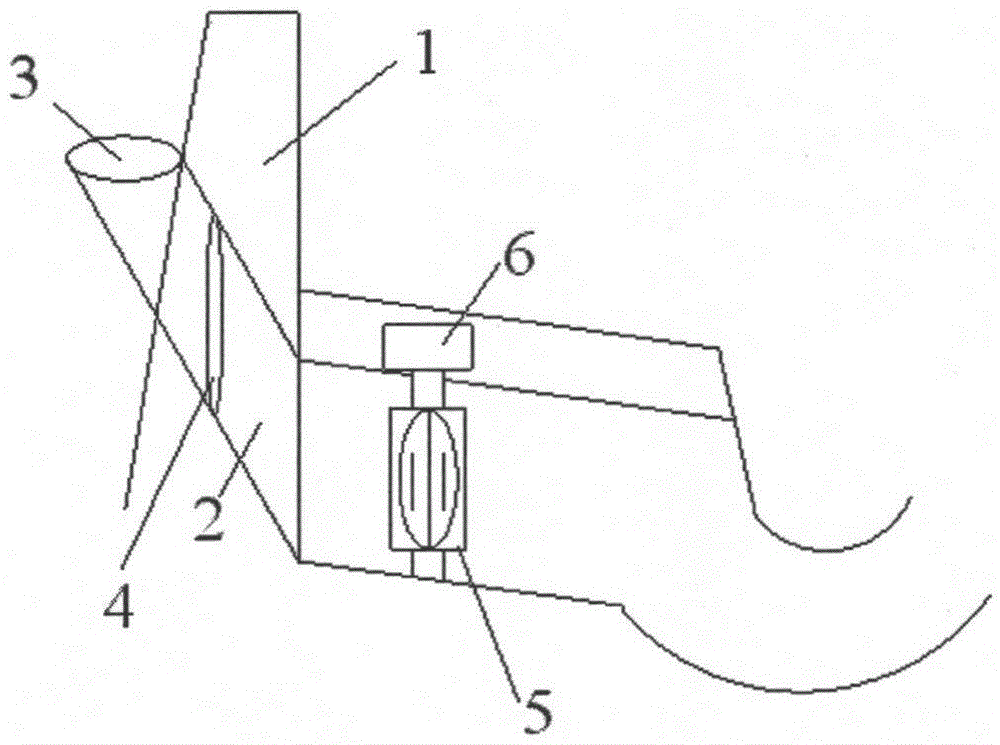

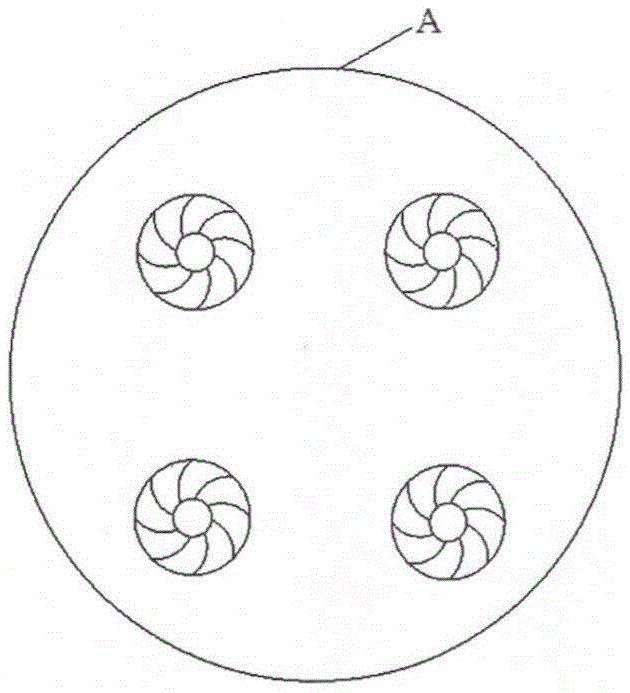

[0035] figure 2 The schematic diagram of the comprehensive hydroelectric power generation system provided for this embodiment, the comprehensive hydroelectric power generation system includes a waterway...

Embodiment 2

[0050] Figure 7 The schematic diagram of the integrated hydroelectric power generation system provided for this embodiment is basically the same as that of Embodiment 1, the difference being that a waterway buffer zone 2-4 is provided on the extension line at the end of the middle section of the waterway 2-2. After the water flow pours down from the middle section 2-2 of the water channel, part of the water falls directly from the water channel diversion section 2-3, and part of the water flows down from the water channel diversion section 2-3 after being buffered by the water channel buffer zone 2-4.

Embodiment 3

[0052] The difference between this embodiment and Embodiment 1 is that: from the upstream to the downstream, only the units of the "circulation type" and "confluence type" power generation modes are arranged in sequence, and the units of the two power generation modes share a waterway and run simultaneously to generate electricity.

[0053] Although the utilization rate of water energy in this way is lower than that of Embodiment 1, it is still higher than that of the traditional hydroelectric power generation system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com