Automatic testing method for key parameters of MEMS gyroscope structure

A key parameter, automatic test technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of omission, long test time, extended frequency sweep test time, etc., to achieve the effect of improving efficiency and shortening test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be further described in conjunction with the drawings and specific embodiments.

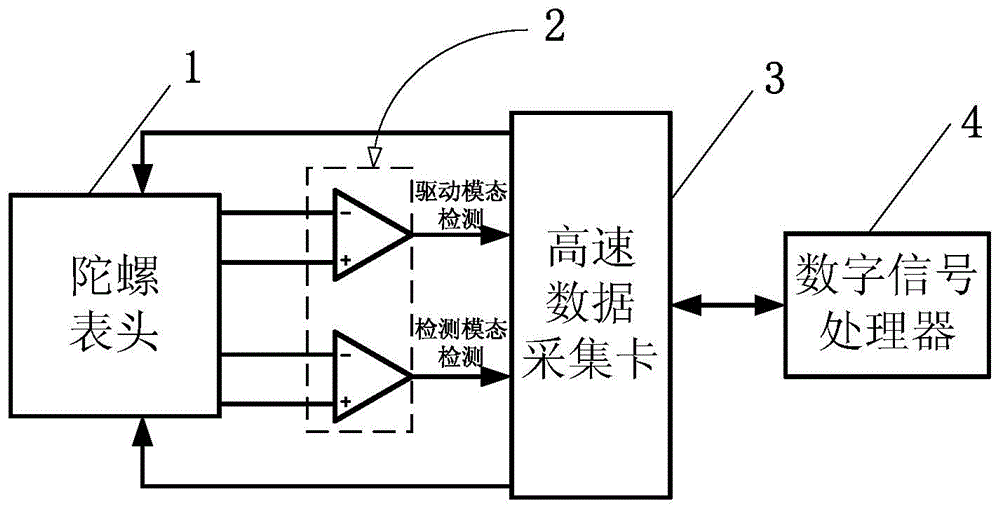

[0031] figure 1 It is a device block diagram for realizing the MEMS gyroscope structure key parameter automatic testing method of the present invention:

[0032] It mainly includes a gyroscope head 1, a test circuit 2, a high-speed data acquisition card 3 and a digital signal processor 4. The gyro meter 1 is connected to the high-speed data acquisition card 3 through the test circuit 2, and the vibration detection signals of the gyro drive mode and the detection mode enter the digital signal processor 4 through the high-speed data acquisition card 3 for processing to obtain the required parameters, and at the same time the digital signal The processor 4 can generate an excitation signal through the acquisition card 3 to drive the gyroscope head 1 .

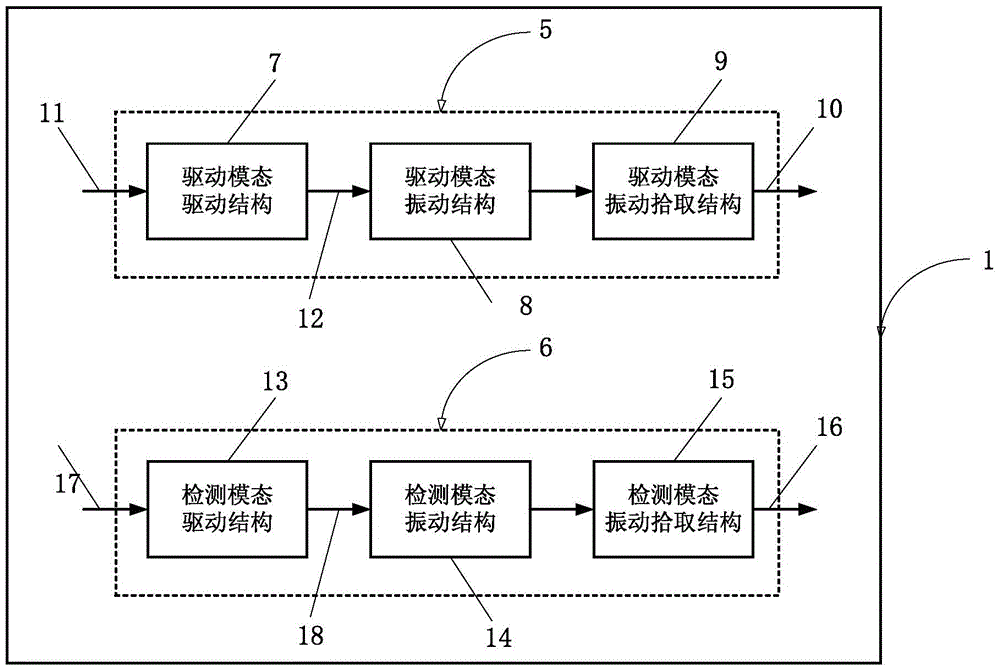

[0033] The MEMS gyroscope targeted by the present invention is a MEMS gyroscope comprising two work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com