Testing system for performance of drying agent of dehumidifying and drying unit of gaseous radioactive waste processing system

A technology of waste gas treatment and drying unit, which is applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of reduced adsorption performance of activated carbon, affecting the life and system availability of activated carbon, outage of waste gas treatment system and upstream system, etc., to achieve convenient operation. , The data results are true and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

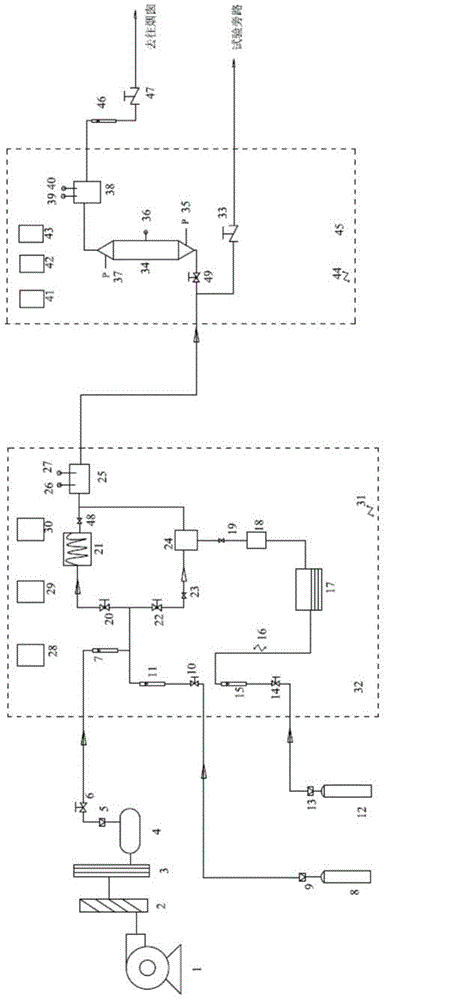

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0012] The invention provides a desiccant performance test system for a dehumidification and drying unit of a radioactive waste gas treatment system, which is used to test the performance of an adsorbent used in a drying bed. The system consists of an adsorption test loop and a drying regeneration loop.

[0013] The structure of the system is as figure 1 As shown, it includes nitrogen supply equipment and compressed air supply equipment. The nitrogen supply equipment and compressed air supply equipment are respectively connected to the first measuring pool 25, and the outlet of the first measuring pool 25 is connected to the inlet of the desiccant test bed 34. , the outlet of the desiccant test bed 34 is connected with the second measuring pool 38, the outlet of the second measuring pool 38 is connected with the chimney, the desiccant test bed 34 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com