Power diode module working junction temperature on-line detection system and detection method

A technology for power diodes and working junction temperature, applied in diode testing, measuring electricity, measuring devices, etc., which can solve the problems of small conduction voltage drop, high bus voltage of voltage sensor, and easy interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

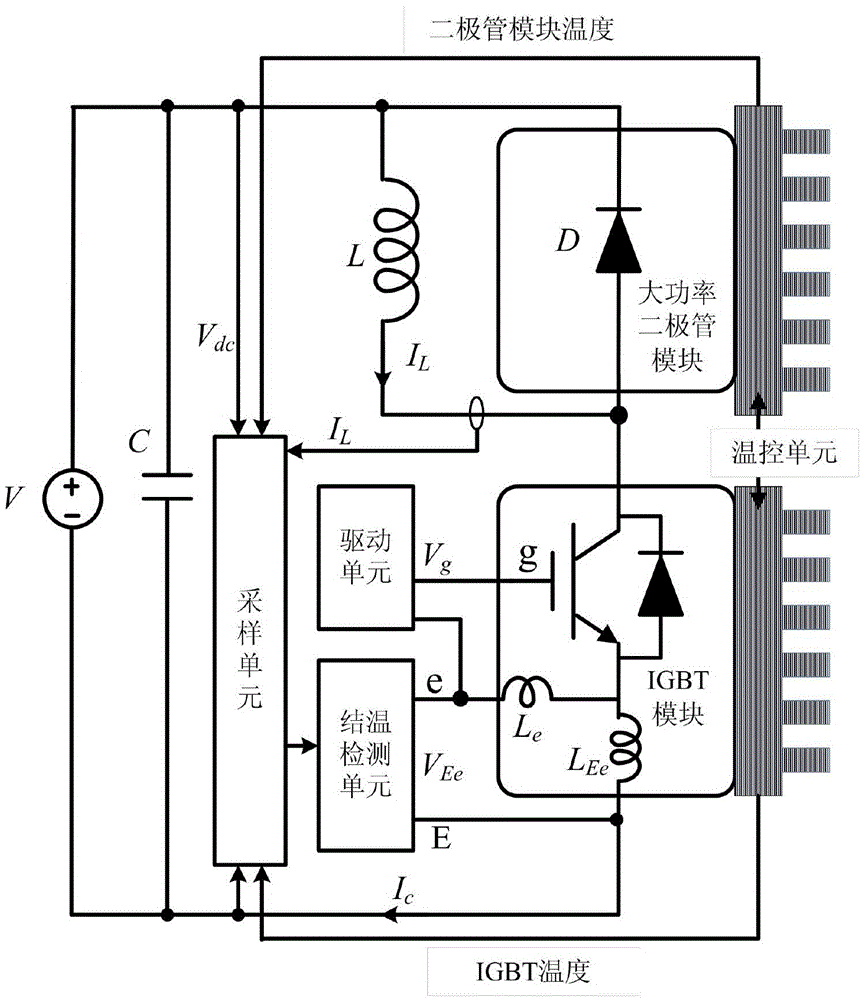

[0039] figure 1 A schematic diagram of the test platform for the operating junction temperature of a power diode module with a two-level half-bridge topology with an inductive load is shown. The entire test platform mainly includes high-power diode module D, high-power IGBT module, drive unit, DC power supply V, DC energy storage capacitor C, freewheeling reactor L, temperature control unit, sampling unit and junction temperature detection unit, of which: diode The cathode terminal of the module D is connected to the positive pole of the DC energy storage capacitor C and the positive pole of the DC power supply V; one end of the freewheeling reactor L is connected to the input terminal of the high-power IGBT module, and the other end is connected to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com