Radio frequency micro-electro-mechanical system (MEMS) switch and fabrication method thereof

A switch and radio frequency technology, applied in the field of radio frequency MEMS switches and their manufacturing, can solve the problems of high driving voltage, poor reliability, and low life, and achieve the effect of reducing driving voltage, improving life and reliability, and low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

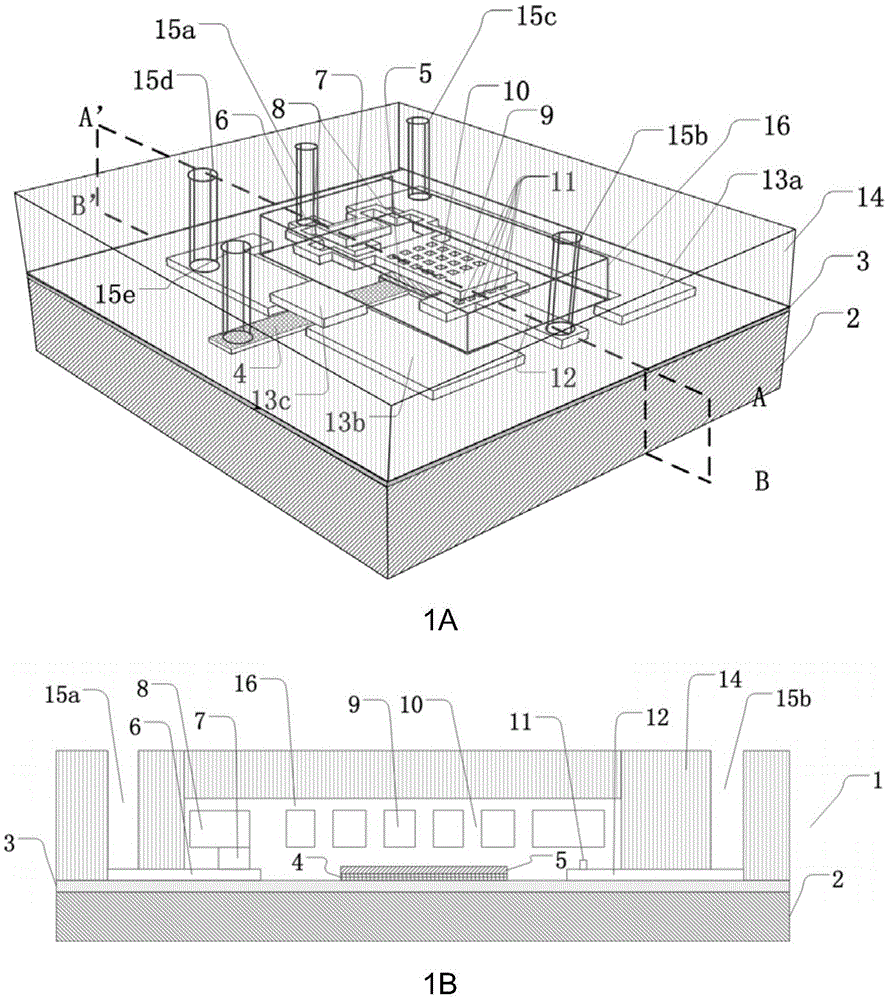

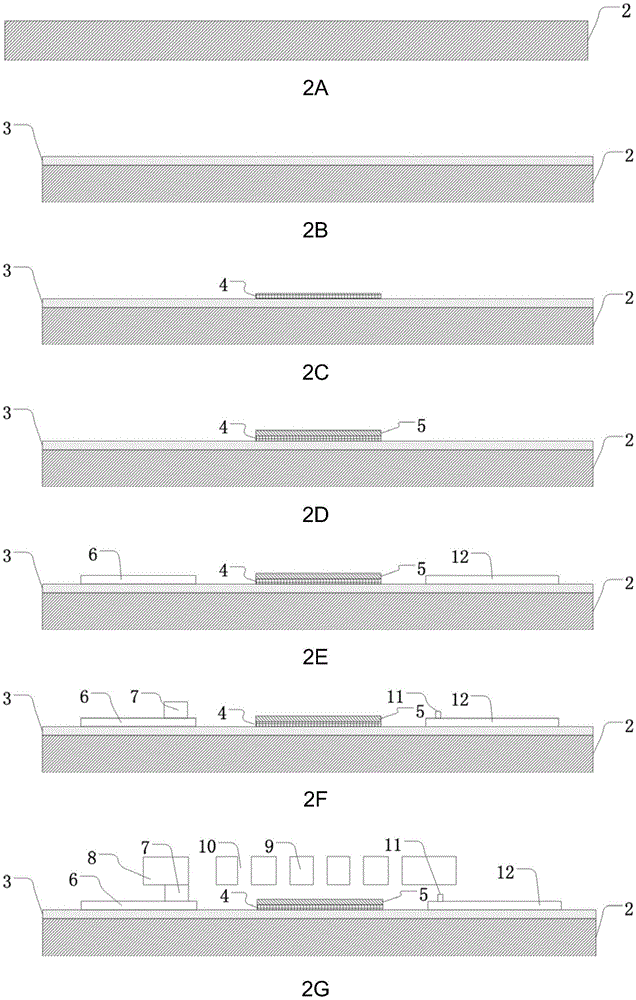

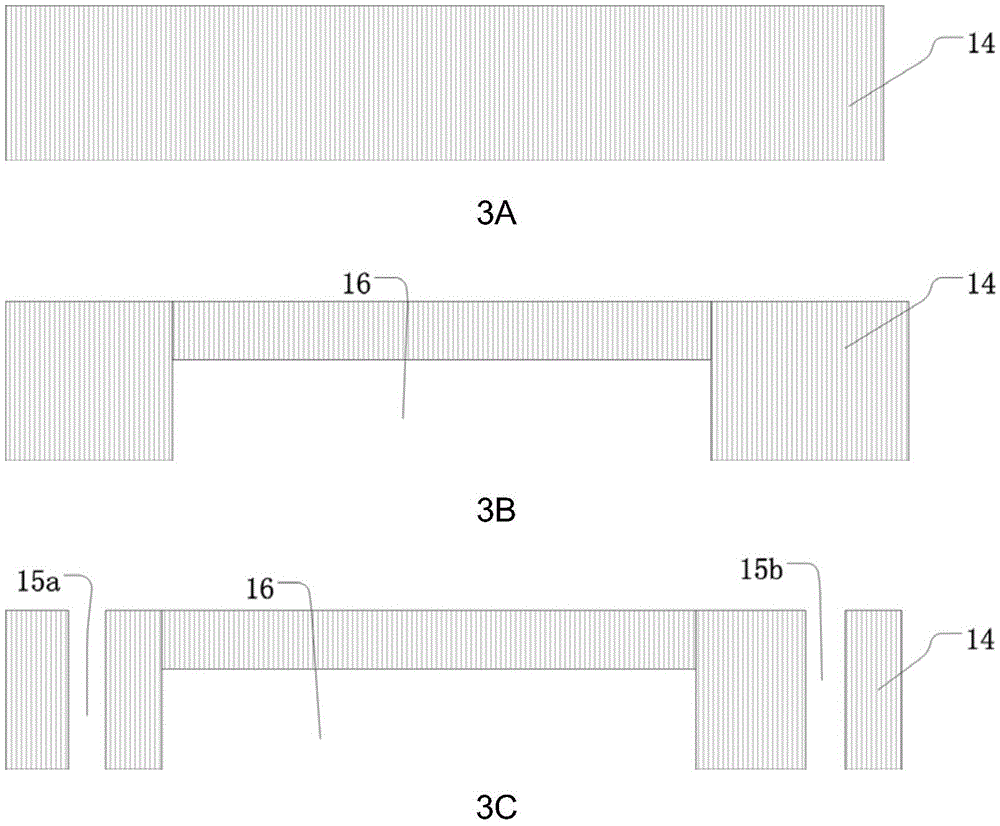

[0036] The present invention proposes a radio frequency MEMS switch, including: a substrate 2, a dielectric layer 3, a drive electrode 4, an isolation layer 5, a signal line input electrode 6, a columnar anchor point 7, two fixed beams 8 with turning structures, and a beam 9. Multi-contact system 11 and signal line output electrode 12 , ground line 13 and cap 14 . Such as figure 1 It is a structural schematic diagram of the radio frequency MEMS switch of the present invention, 1A is its side view, and 1B is its edge figure 1 Sectional view of the AB-A'B' section of A.

[0037] Wherein each fixed beam 8 comprises at least 6 turning parts, such as Figure 5 Shown is a structure of the fixed beam 8 of the present invention, wherein the turning part is a right angle, and a fixed beam has 7 right-angle turning parts, and the fixed beam is divided into 8 sections. The design of the turning structure reduces the elastic coefficient of the beam 9 .

[0038]There is a dielectric la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com