Formation method of metal interconnection structure

A metal interconnection structure, metal layer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as electromigration failure, high resistance, disconnection, etc., to improve performance and reduce defects that form voids Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] As mentioned in the background art, using the existing technology, during the process of forming the metal interconnection structure in the dielectric layer, a larger volume of voids will be formed in the conductive plugs and interconnection lines, thereby reducing the metal interconnection structure. performance. Especially as the process node of the integrated circuit continues to decrease, the aspect ratio of the trench formed in the dielectric layer for forming the metal interconnection structure increases, so that the gap formed in the metal interconnection structure takes up the space between the conductive plug and the interconnection structure. The space ratio of the wiring is gradually increasing, which has a more serious impact on the performance of the conductive plug and the interconnection line. Analyze the cause of the gap:

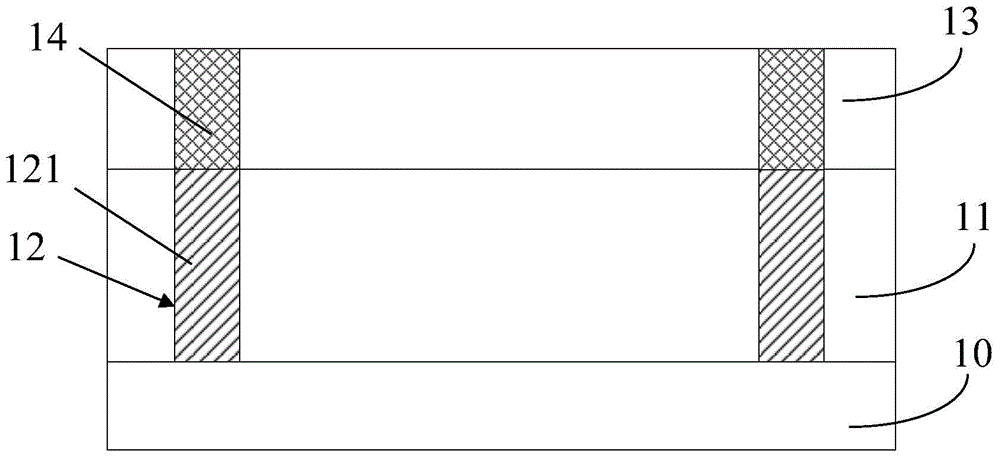

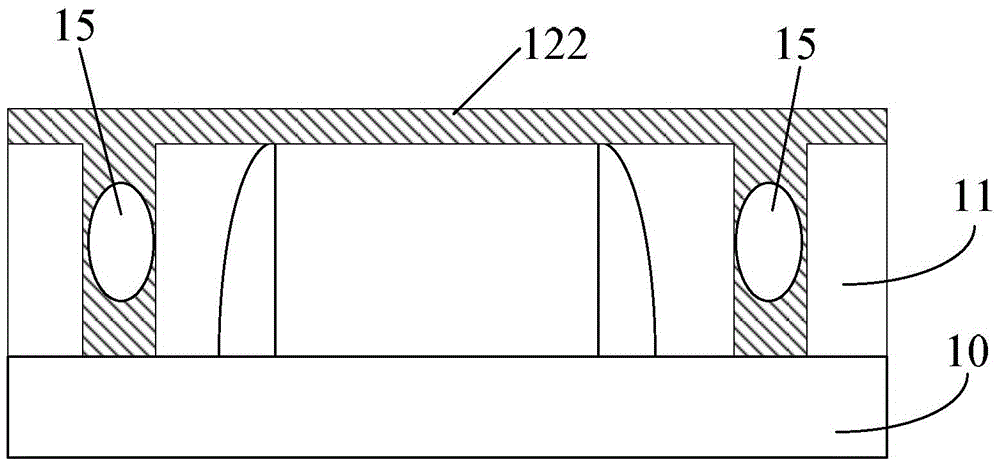

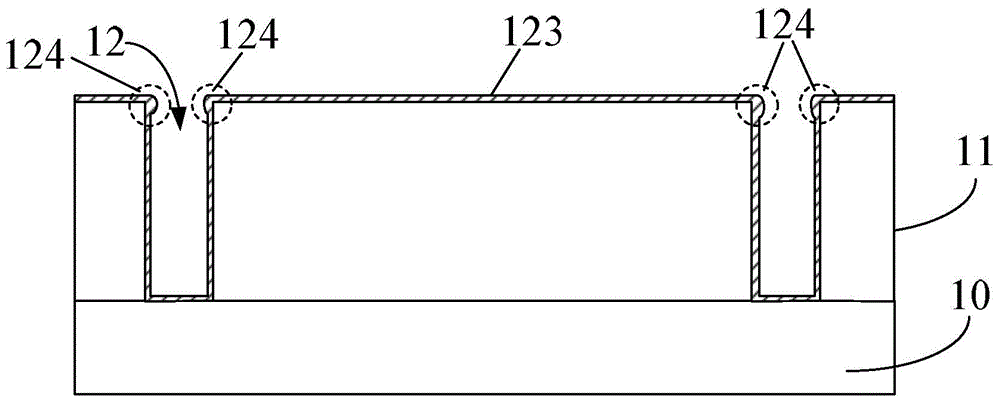

[0044] In the existing technology, copper is mostly used as the material of the metal interconnection structure, refer to image 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com