Coating device for mixed solution of precursor and surfactant and use method of coating device

A technology of surfactant and precursor solution, applied in the field of coating equipment for mixed solutions, can solve the problems of multiple pinholes, inability to flatten, and difficulty in infiltration of the electron/hole transport layer, and achieves uniform film thickness distribution and improved Coverage, shrinkage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

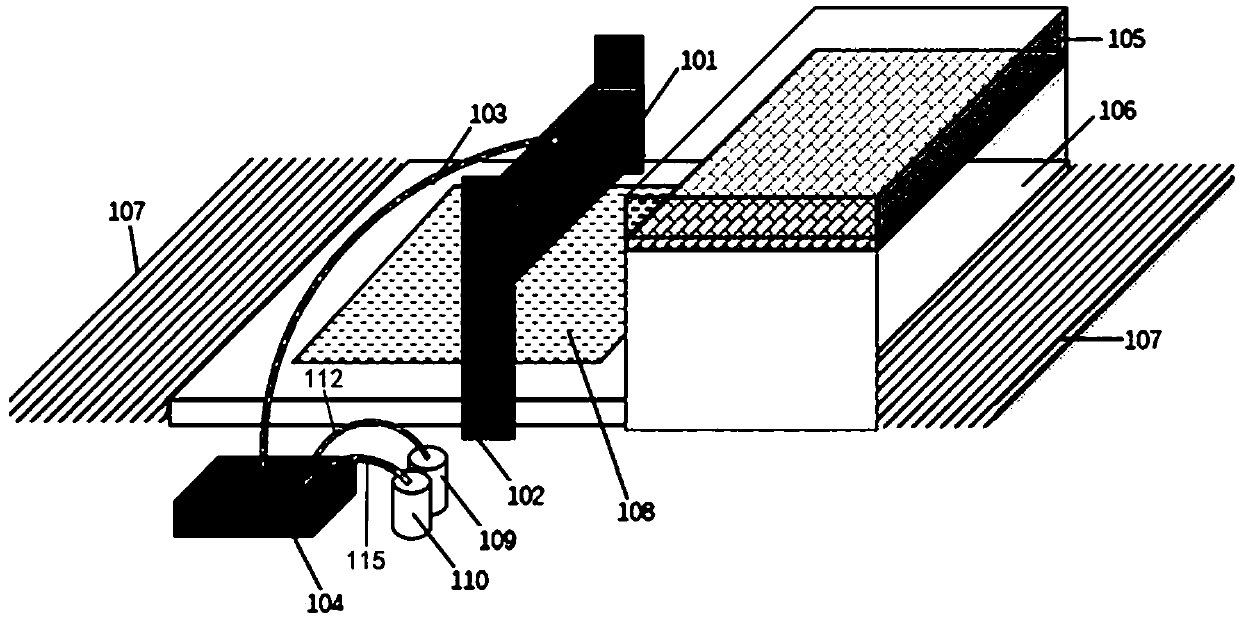

[0054]The present invention also discloses a method for preparing a perovskite solar cell. In the process of preparing the perovskite solar cell, the coating equipment for a mixed solution of a precursor and a surfactant as described above is used, including the following steps:

[0055] S1. According to the preparation method of a mixed solution of a precursor and a surfactant as described above, the divalent precursor and the surfactant solution are injected into different raw material bottles, and the two raw material bottles are respectively passed through the pipeline and injected The pump is connected, and the syringe pump sucks the divalent precursor solution and the surfactant solution into the mixing chamber at the same time according to the set volume ratio of 1~1000 for mixing. After stirring, a mixed solution of the precursor and the surfactant is obtained.

[0056] S2. Place the substrate 108 on which the conductive layer and the electron / hole transport layer have ...

Embodiment 1

[0066] The perovskite thin film layer is prepared by using the existing two-step method technology. First, 1mol / L PbI was coated on the substrate prepared with PTAA electron / hole transport layer by slot coating 2 The divalent precursor solution of perovskite, wherein the divalent precursor solvent is DMF and DMSO in the divalent precursor solution of perovskite, and the volume ratio of DMF and DMSO is 9:1, then, to the substrate after coating PbI-containing 2 film layer. Then in PbI 2 A thin film layer of MAI monovalent precursor is prepared on the surface of the thin film layer to obtain a thin film layer of perovskite.

[0067] Among them, PbI 2 Slot coating conditions of divalent precursor solution: at a temperature of 25°C and a humidity of 30%RH, the coating liquid volume is 1ul / cm 2 , the slit width is 100um, and the coating speed is 5cm / s. Drying conditions after coating: hot air drying, the wind speed near the surface of the substrate is 2m / s, the temperature nea...

Embodiment 2

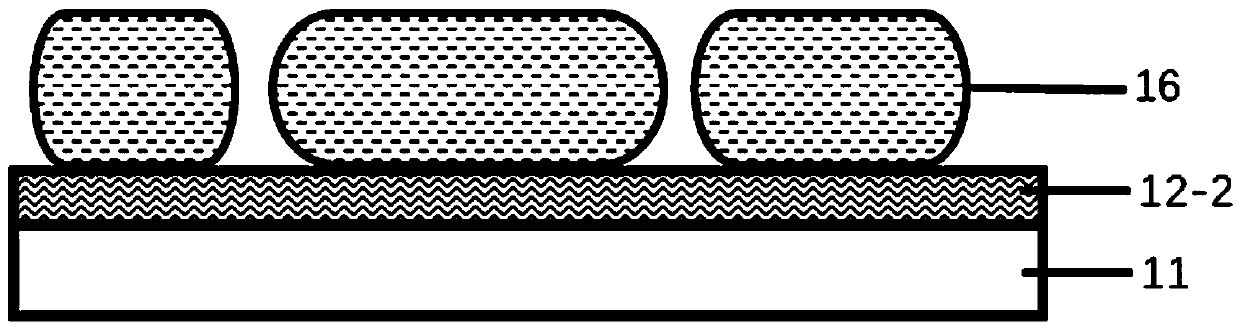

[0070] Using a two-step process, adding a surfactant to the divalent precursor solution coated with perovskite, and then coating the monovalent precursor solution after coating, the following is obtained: Image 6 Schematic cross-sectional view of the shown perovskite thin film layer after coating.

[0071] Conductive layer 11 and electron / hole transport layer 12-2 are sequentially prepared on the substrate, and the perovskite thin film layer 16 prepared on electron / hole transport layer 12-2, due to the electron / hole transport layer 12- 2 is coated with a divalent precursor solution of perovskite containing a surfactant, and the lower surface of the perovskite thin film layer 16 has a surfactant 17. In the illustration, the dots of surfactant 17 are hydrophilic groups, and the curves are lipophilic groups. The hydrophilic groups are distributed on the side close to the perovskite thin film layer 16 , while the lipophilic groups are distributed on the air side of the lipophili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com