Single-chip microcomputer brushless direct-current motor rotor position detecting protector

A technology of rotor position detection and brushed DC motor, which is applied in the direction of electronic commutator, emergency protection circuit device for limiting overcurrent/overvoltage, circuit device, etc., to achieve high control precision, stable signal and low control power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

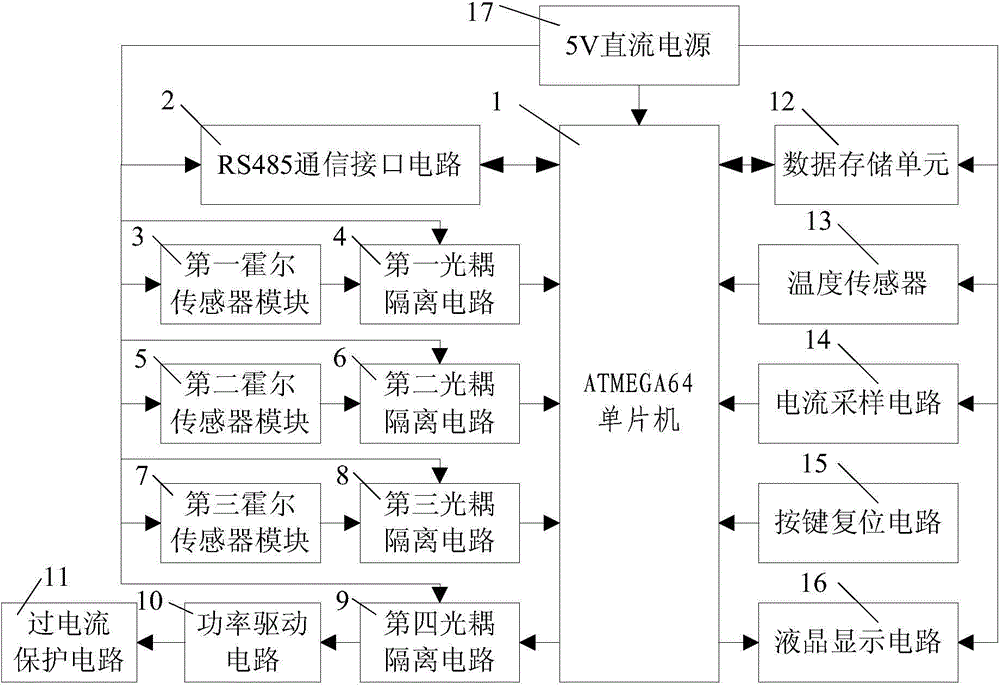

[0026] Such as figure 1 Shown, the present invention comprises ATMEGA64 single-chip microcomputer 1, 5V DC power supply 17, connects with ATMEGA64 single-chip microcomputer 1 and is used for the RS485 communication interface circuit 2 of data communication, connects with ATMEGA64 single-chip microcomputer 1 and is used for real-time storage brushless DC motor rotor position The data storage unit 12 of temperature and electric current data and be used for detecting and protecting the power drive module driven by the brushless DC motor, and a plurality of sensor components for detecting rotor position information in real time; The input terminal of described ATMEGA64 single-chip microcomputer 1 is connected with for The temperature sensor 13 that detects the temperature information around the rotor of the brushless DC motor, the current sampling circuit 14 for detecting the loop current of the control end of the brushless DC motor, and the button reset circuit 15 for fault recove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com