Chemical-mechanical planarization of polymer films

A technology of chemical mechanics and polishing compositions, applied in other chemical processes, chemical instruments and methods, polishing compositions containing abrasives, etc., can solve problems such as limiting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

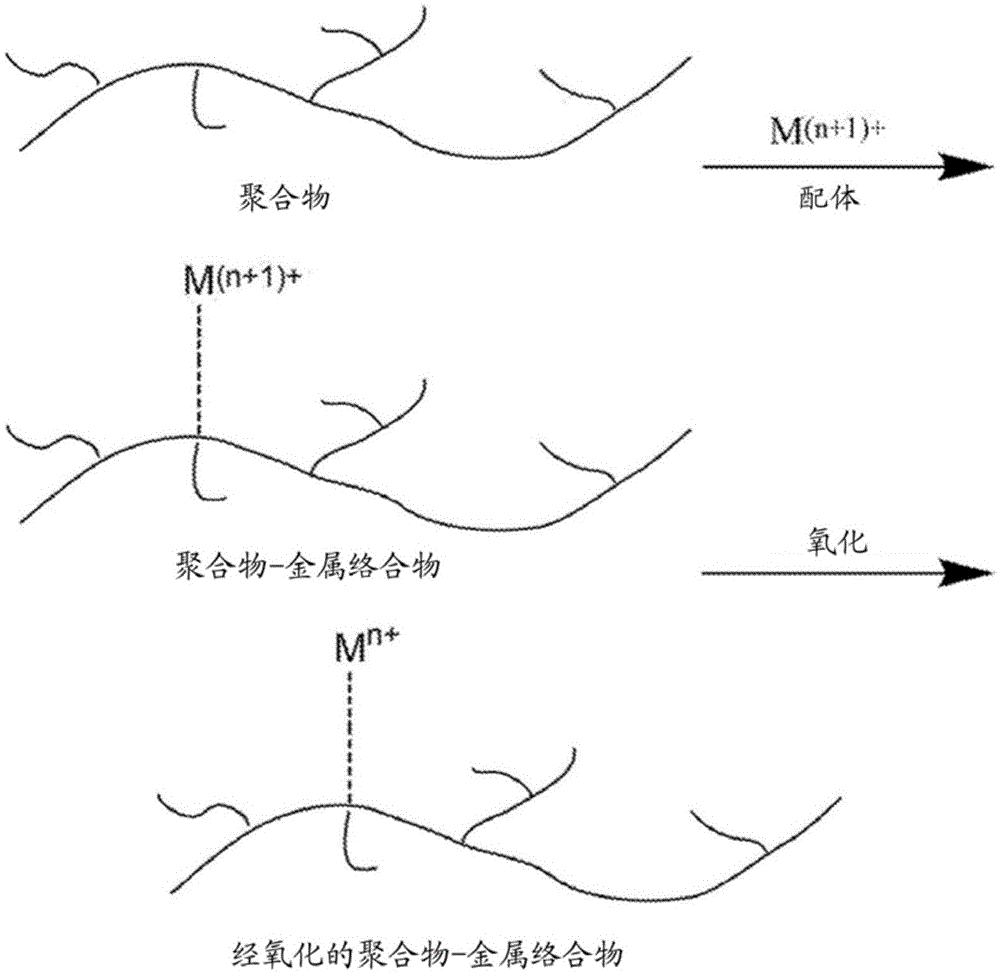

Method used

Image

Examples

Embodiment 1

[0050] This example shows that the combination of a metal ion which is a Lewis acid and a ligand which is an aromatic carboxylic acid, an aromatic sulfonic acid, an aromatic acid amide, an amino acid, or a hydroxyl-substituted N-heterocycle is effective in the transfer of a polymer membrane. Effectiveness in removal rate.

[0051] Spin-on-carbon (SoC) polymer wafers were polished with different polishing compositions using conventional CMP equipment. The wafers were polished with seven polishing compositions (Polishing Compositions 1A to 1G), each containing only metal ions, only ligands, or both metal ions and ligands, as described in Table 1 below.

[0052] Each of the polishing compositions 1A to 1G contained 0.05% by weight of cerium oxide particles in an aqueous carrier and the pH was adjusted to 2.3 with ammonium hydroxide, if necessary. Polishing Compositions 1A and 1B contain 5 mM Al 3+ , Polishing Compositions 1C and 1D contain 5mMFe 3+ , and Polishing Compositions...

Embodiment 2

[0058] This example shows that the combination of a metal ion which is a Lewis acid and its ligand which is an aromatic carboxylic acid, aromatic sulfonic acid, aromatic acid amide, amino acid, or hydroxy-substituted N-heterocycle efficiently removes Polymer films while exhibiting minimal (or no) removal of tetraethoxysilane (TEOS).

[0059] Spin-on-carbon (SoC) polymer wafers and tetraethoxysilane (TEOS) wafers were polished with different polishing compositions using conventional CMP equipment. The wafers were polished with nine polishing compositions (Polishing Compositions 2A to 2I), as described in Table 2. Polishing compositions 2B, 2C, 2D, 2G, 2H, and 2I were used to polish SoC polymer wafers, but not TEOS wafers. Each of Polishing Compositions 2A to 21 contained 5 mM Fe in an aqueous carrier 3+ Particle with 0.05% by weight of cerium oxide, and adjust the pH to 2.3 with ammonium hydroxide if necessary. Each polishing composition also contained ligands, as described ...

Embodiment 3

[0067] This example demonstrates that the combination of a metal ion which is a Lewis acid and a ligand which is an aromatic carboxylic acid, aromatic sulfonic acid, aromatic acid amide, amino acid, or hydroxy-substituted N-heterocycle effectively removes aggregated physical film.

[0068] Spin-on-carbon (SoC) polymer wafers were polished with different polishing compositions using conventional CMP equipment. The wafers were polished with 14 polishing compositions (Polishing Compositions 3A to 3N), as described in Table 3. Each of Polishing Compositions 3A to 3N contained 5 mM Fe in an aqueous carrier 3+ with 0.05% by weight of cerium oxide particles, and adjust the pH to the value recorded in Table 3 with ammonium hydroxide if necessary. The aqueous carrier used in each polishing composition was water. Each polishing composition also contained ligands, as described in Table 3.

[0069] Substrates were finished with EPIC on a Logitech benchtop polisher TM D200 pads (Cabot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com