Ambrisentan tablet and preparation method thereof

A technology for ambrisentan and sentan tablet, which is applied in the field of ambrisentan tablet and its preparation, can solve the problems that ambrisentan preparation needs to be in-depth, reported, and there is no ambrisentan preparation technology, etc., and achieves stable and controllable quality , reduce dosage deviation, and promote the effect of disintegration and dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1: Preparation of Ambrisentan Tablets (Specification: 10mg) by Powder Direct Compression Process

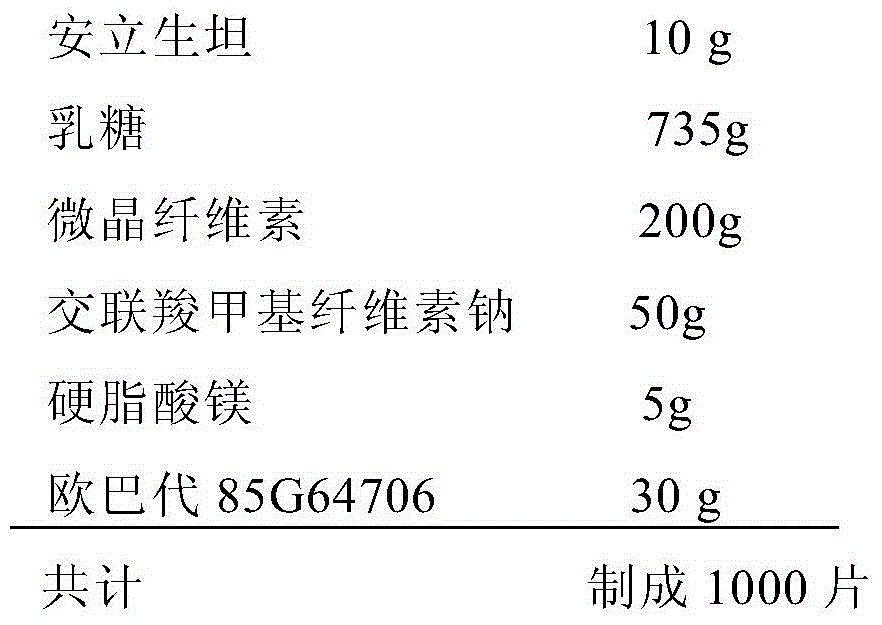

[0056] prescription:

[0057]

[0058] The method is as follows:

[0059] 1) Take the ambrisentan of prescription quantity, carry out micronization to particle diameter and be 5-50 micron,

[0060] 2) Mix the auxiliary materials lactose, microcrystalline cellulose, croscarmellose sodium, and magnesium stearate, pass through a 60-mesh sieve, add to ambrisentan, and mix evenly in a mixer;

[0061] 3) compressing the material in step 2) on a tablet press to obtain ambrisentan tablets;

[0062] 4) Coating Amritsentansu Tablets in a high-efficiency coating machine, the coating powder is Opadry 85G64706, using purified water 4 times the weight of the coating powder, stirring evenly to disperse the coating powder evenly, and preparing The coating solution is ready for use; the coating parameters are: air inlet temperature 55-60°C, material temperature 38-40°C, host ...

Embodiment 2

[0064] Example 2: Preparation of Ambrisentan Tablets (Specification: 10mg) by Powder Direct Compression Process

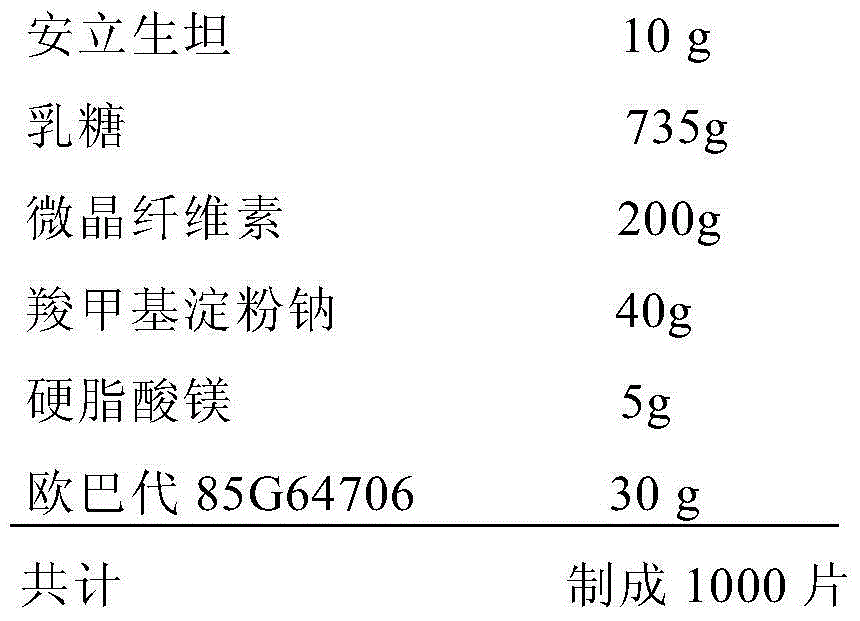

[0065] prescription:

[0066]

[0067] The method is as follows:

[0068] 1) Take the ambrisentan of prescription quantity, carry out micronization to particle diameter and be 30-60 micron,

[0069] 2) Mix the auxiliary materials lactose, microcrystalline cellulose, sodium carboxymethyl starch, and magnesium stearate, pass through a 40-mesh sieve, add to ambrisentan, and mix evenly in a mixer;

[0070] 3) compressing the material in step 2) on a tablet press to obtain ambrisentan tablets;

[0071] 4) Coating Amritsentansu Tablets in a high-efficiency coating machine, the coating powder is Opadry 85G64706, using purified water 4 times the weight of the coating powder, stirring evenly to disperse the coating powder evenly, and preparing The coating solution is ready for use; the coating parameters are: air inlet temperature 60-65°C, material temperature 35-40°C...

Embodiment 3

[0072] Example 3: Preparation of Ambrisentan Tablets (Specification: 10mg) by Powder Direct Compression Process

[0073] prescription:

[0074]

[0075]

[0076] The method is as follows:

[0077] 1) Take the ambrisentan of prescription quantity, carry out micronization to particle diameter and be 60-100 micron,

[0078] 2) Mix the auxiliary materials mannitol, microcrystalline cellulose, sodium carboxymethyl starch, and magnesium stearate, pass through an 80-mesh sieve, add to ambrisentan, and mix evenly in a mixer;

[0079] 3) compressing the material in step 2) on a tablet press to obtain ambrisentan tablets;

[0080] 4) Coating Amritsentansu Tablets in a high-efficiency coating machine, the coating powder is Opadry 85G64706, using purified water 4 times the weight of the coating powder, stirring evenly to disperse the coating powder evenly, and preparing The coating solution is ready for use; the coating parameters are: air inlet temperature 55-60°C, material temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com