Method for improving filtering quality of coal slurry water by compounding biological and nonbiological flocculants for coal

A technology of biological flocculants and filtration performance, applied in biological water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Pollution and other problems, to achieve the effect of reducing adverse effects, reducing restrictions, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

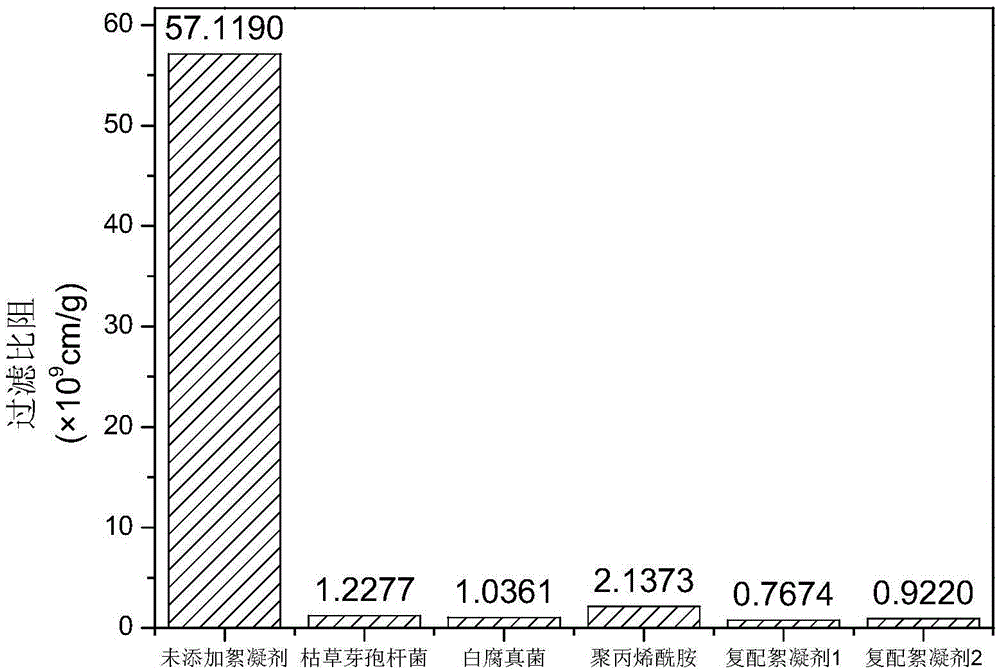

[0049] The filtration performance of example 1 coal slime water:

[0050] 1) Take 500mL of coal slime water with a concentration of 40g / L and a pH value of 7, and stir it with a magnetic slow speed stirrer for 5min;

[0051] 2) After standing for 30 minutes, pour off the supernatant, take 200mL of coal slime water flocs to carry out the Buchner funnel filtration test, the calculated filter specific resistance of coal slime water flocs is 57.119×10 9 cm / g.

example 2

[0052] Example 2 adds the coal slime water filtration performance of coal biological flocculant Bacillus subtilis:

[0053] 1) Take 450mL of coal slime water with a concentration of 50g / L, stir evenly, and then add 2% CaCl 2 Coagulant aid 5mL, stir with a magnetic slow speed stirrer for 1min;

[0054] 2) Add 10mL of coal bioflocculation agent Bacillus subtilis, add coal slime water to 500mL, adjust the pH value of the coal slime water to 7 with a pen-type pH meter, and then stir slowly with a magnetic stirrer for 5 minutes;

[0055] 3) After standing for 30 minutes, pour off the supernatant, take 200mL of coal slime water floc to carry out the Buchner funnel filtration test, the calculation shows that the filtration specific resistance of coal slime water floc is 1.2277×10 9 cm / g.

example 3

[0056] Example 3 adds the coal slime water filtration performance of coal bioflocculant white-rot fungus:

[0057] 1) Take 450mL of coal slime water with a concentration of 40g / L, stir evenly, and then add 2% CaCl 2 Coagulant aid 10mL, stir with a magnetic slow speed stirrer for 1min;

[0058]2) Add 15mL of coal bioflocculation agent Bacillus subtilis, add coal slime water to 500mL, adjust the pH value of the coal slime water to 7 with a pen-type pH meter, and then stir slowly with a magnetic stirrer for 5 minutes;

[0059] 3) After standing for 30 minutes, pour off the supernatant, take 200mL of coal slime water floc to carry out the Buchner funnel filtration test, the calculation shows that the filtration specific resistance of coal slime water floc is 1.0361×10 9 cm / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com