Vertical type no-layering sludge aerobic fermentation system and treatment method

An aerobic fermentation and treatment method technology, applied in sludge treatment, biological sludge treatment, etc., can solve the problems of high cost, more conditioners, and increased stacking height, so as to save energy, ensure uniformity, and ensure good running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

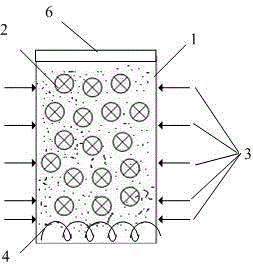

[0061] This embodiment describes in detail the sludge aerobic fermentation bin of the present invention, and its structural schematic diagram is as follows figure 1 As shown, it includes a fermentation bin 1 , an air supply device 3 and a discharge device 4 .

[0062] Among them, the mixed material in the fermentation bin 1 is filled with a support body 2, which has a predetermined void ratio, and is used to provide a supporting skeleton for the mixed material, and the edges of adjacent support bodies 2 are handed over to support each other for transmission. Gravity, when the mixed material is piled up, the weight is borne by the support body 2 and will be transferred to each other. The weight of the upper mixed material is transferred to the lower support body 2 through the support body, and will not act on the lower mixed material, avoiding the The superposition of weight causes poor ventilation and oxygen supply in the mixed material at the bottom, which affects the aerobic...

Embodiment 2

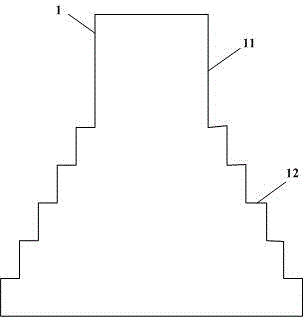

[0071] This embodiment is on the basis of embodiment 1, fermenting chamber 1 has been improved, as figure 2 Shown is a schematic diagram of fermentation chamber 1 . In this example, according to the characteristics of the sludge aerobic fermentation process for air supply and the law of temperature change, the fermentation chamber is set up as a stepped structure from top to bottom, and the sludge has to go through the stage of feeding temperature, high temperature and so on from top to bottom. Fermentation stage, stabilization stage and water content stripping stage.

[0072]As shown in the figure, the fermentation bin 1 includes a first part 11 and a second part 12. The first part 11 corresponds to the feed heating up stage and the high-temperature fermentation stage. requirements and the height of the daily feed; the second part 12 corresponds to the subsequent stabilization stage and moisture content blow-off stage, adopting a stepped design with sudden expansion on both...

Embodiment 3

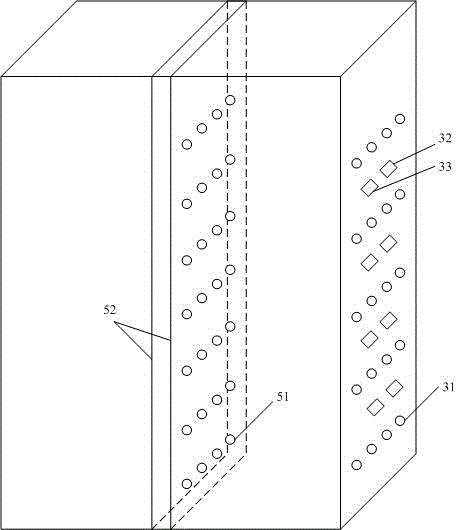

[0075] In this embodiment, on the basis of Embodiment 1, an air-inducing device 5 is added, and its three-dimensional view is as follows: image 3 As shown, the air-inducing device 5 is detachably arranged in the fermentation bin 1, and the fermentation bin 1 is divided into two chambers on the left and right. The air-inducing device includes two assembled panels 52, which are easy to disassemble and clean; the air-inducing device 5 It is a structure closed up and down, and the panel 52 is arranged face-to-face with the side surface provided with the air supply port 31; A plurality of return air outlets 51 arranged side by side; the upper part of the air induction device 5 has a bypass for connecting the induced draft fan.

[0076] In this embodiment, the wind pressure of the air induction device 5 is less than the wind pressure of the air supply device 3, and this wind pressure difference can ensure that the air intake is greater than the air outlet, and the wind is forced to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com