Method for preparing scratch-resistance alkyd resin used for PU furniture paint

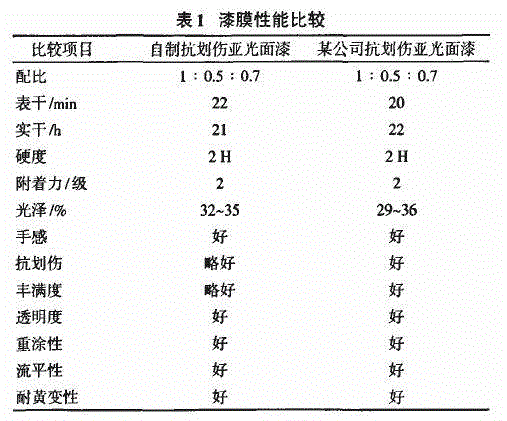

A kind of alkyd resin and preparation technology, applied in the direction of coating, polyester coating, etc., can solve the problems of poor scratch resistance, poor fullness of paint film, poor transparency, etc., and achieve extremely high transparency for recoating Good, good scratch resistance, good fullness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below with reference to the examples, but the embodiments of the present invention are not limited thereto.

[0021] The preparation process of anti-scratch alkyd resin for PU furniture paint is generally produced by one-step feeding solvent method. The solvent method has a reflux device and has less material loss. The relative molecular mass distribution is uniform to ensure product quality, which specifically includes the following steps:

[0022] S1, put the raw material into the reaction kettle, pass N 2 Raise the temperature until there is reflux and stop passing N 2 , the types of raw materials and their mass percentages are: 19-21% oleic acid, 20-24% phthalic anhydride, 0.5-0.7% maleic anhydride, 2-4% trimethylolpropane, 9-11% pentaerythritol, ethylene glycol 5-7%, adipic acid 3-4%, reflux xylene 2%, xylene or butyl acetate 33-37%;

[0023] S2. Heat up to 185°C and keep warm for 1 hour. In actual applic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com