A kind of heavy oil coking method

A technology for heavy oil and coking raw materials, applied in the field of heavy oil coking, can solve the problem of not being able to improve the coking performance of heating furnace tubes at the same time, and achieve the effects of reducing processing steps and processing difficulty, eliminating coke cleaning steps, and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

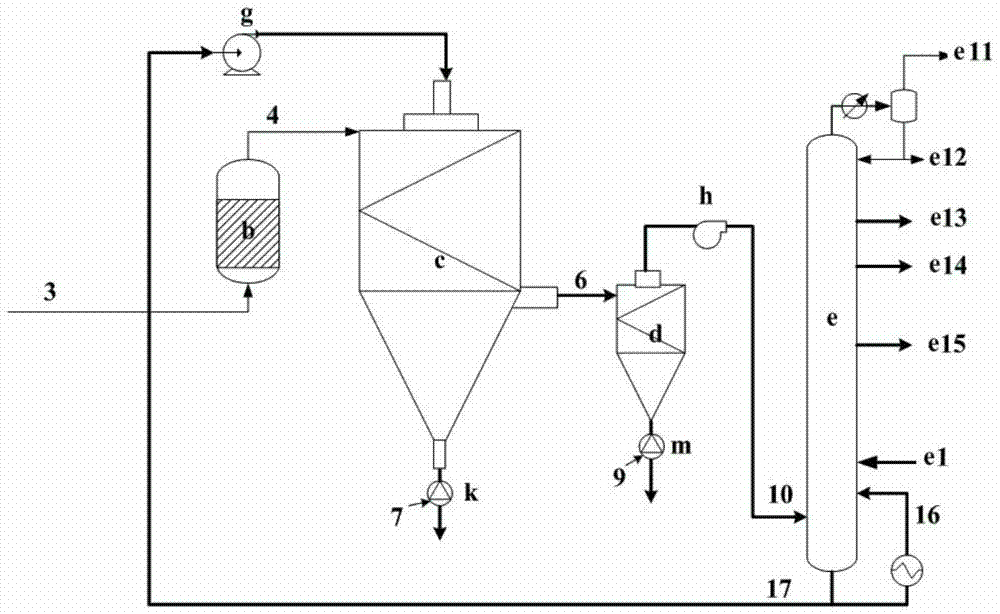

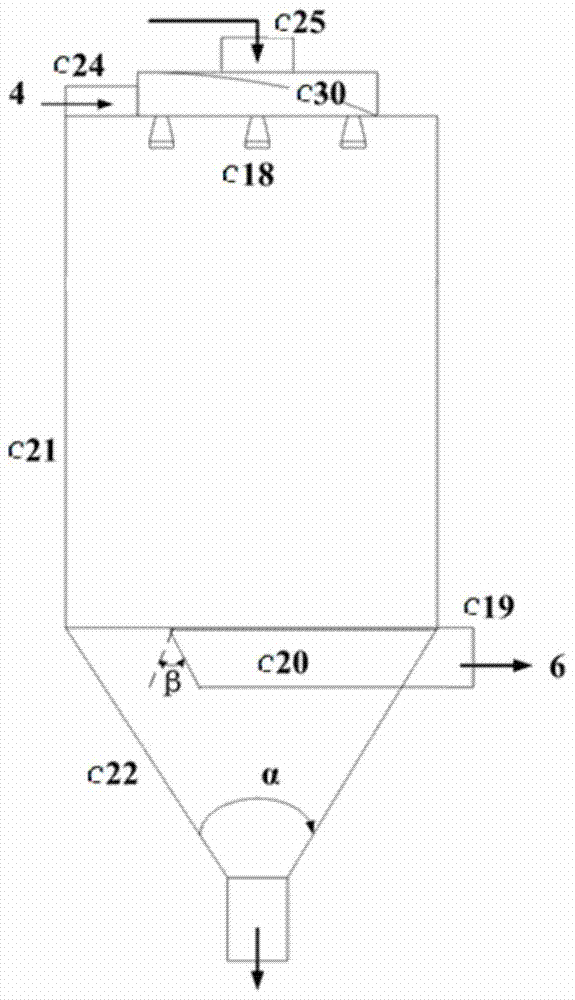

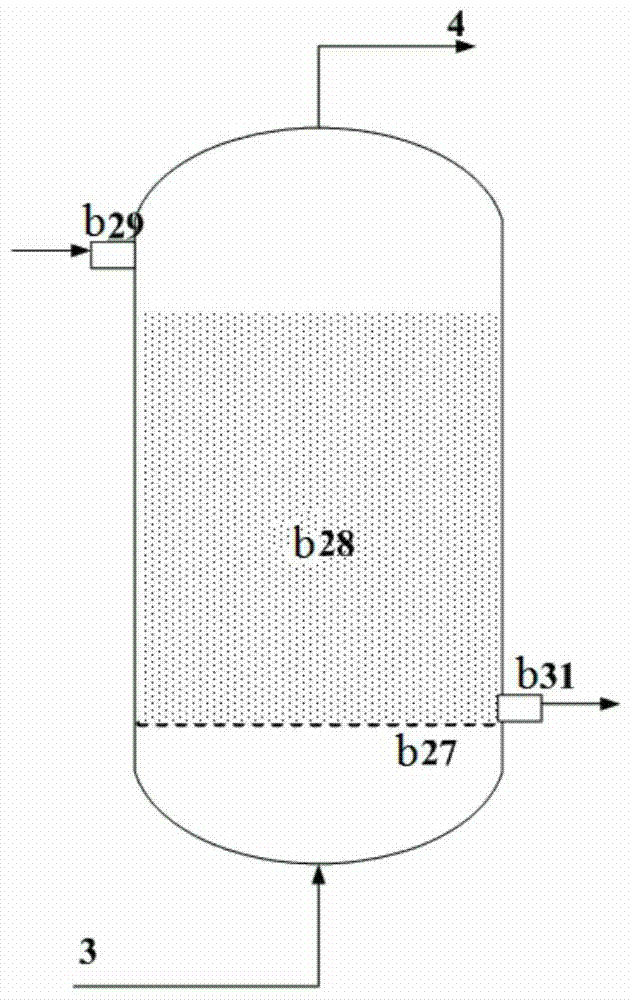

[0045] The present invention does not specifically limit the source and introduction method of the heavy oil coking raw material, for example, the heavy oil coking raw material can be various existing heavy oil raw materials that can be used for coking, and the heavy oil coking raw material can be passed through a heating furnace After being heated to 50-400°C, it is introduced into the spray coking tower c. According to a preferred embodiment of the present invention, the heavy oil coking method further includes introducing feedstock oil into the fractionation tower e from a feedstock inlet e1 arranged below the side of the fractionation tower e, and the feedstock oil and the The bottom reflux oil is mixed at the bottom of the fractionation tower e and introduced as coking raw material 17 into the spray coking tower c for atomization, heat exchange and coking reaction. Therefore, the coking problem in the furnace tube of the heating furnace can be completely avoided, and beca...

Embodiment 1-3

[0053] Examples 1-3 are used to illustrate the heavy oil coking method provided by the present invention.

[0054] The feedstock oil is introduced into the fractionation tower e from the feedstock inlet e1 of the fractionation tower e for preheating, and the feedstock oil obtained after preheating is introduced into the spray coking tower c through the feedstock inlet c25 and atomized through the atomizing nozzle c18 to obtain Atomized small droplets with a liquid size of 20-500 μm, the regenerated flue gas 3 is deoxidized through the coke reactor b, and the deoxygenated deoxygenated flue gas 4 (wherein the oxygen content is 0.1 volume %) passes through the top of the spray coking tower c The hot air inlet c24 is introduced into the spray coking tower c and contacts with the above-mentioned atomized small liquid droplets to make it reach the coking temperature and carry out the coking reaction. The bottom of the lower cone collection area c22 is collected, and the mixture 6 of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com