Efficient, energy-saving and environment-friendly pump for pumping lubricating oil

A high-efficiency, energy-saving, lubricating oil technology, applied in the direction of lubricating pumps, engine lubrication, pumps, etc., can solve problems such as crankshaft locking, engine oil pressure that cannot be automatically adjusted, and engine pulling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

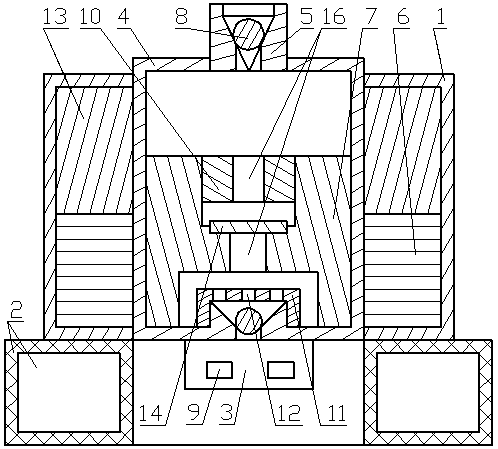

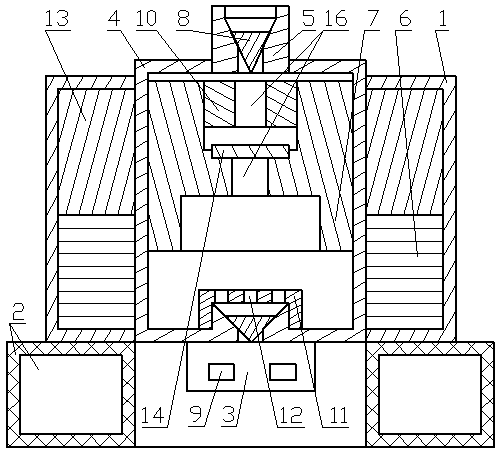

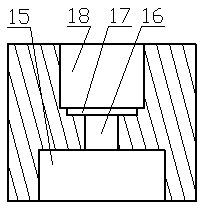

[0070] The high-efficiency energy-saving pump lubricating oil environmental protection pump of the present invention mainly includes a protective shell 1, an annular floating body 2, an upper magnet 13, a lower magnet 6, an oil pump shell 4, an oil inlet hole, a sealing ball 8 or a sealing cone 8, a sealing plate 14, a limiting cap 11, Response magnetic piston 7, fixed plug 10, inner taper hole, oil through hole 16, oil outlet valve, filter 3, magnetic field controller.

[0071] An upper magnet 13 and a lower magnet 6 are installed in the protective shell 1, the upper magnet 13 is fixed on the upper part outside the oil pump shell 4, the lower magnet 6 is fixed on the lower part outside the oil pump shell 4, and the protective shell 1 is fixed on the oil pump shell 4. The outside protects the coil of the upper magnet 13 and the lower magnet 6; the outer lower side of the protective shell 1 is fixed with an annular floating body 2, and the lower end of the annular floating body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com