High-low-temperature high-pressure adsorption and desorption testing device and method

A high-pressure adsorption and test device technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of complex operation, low experimental efficiency, and inability to adsorption and desorption experiments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

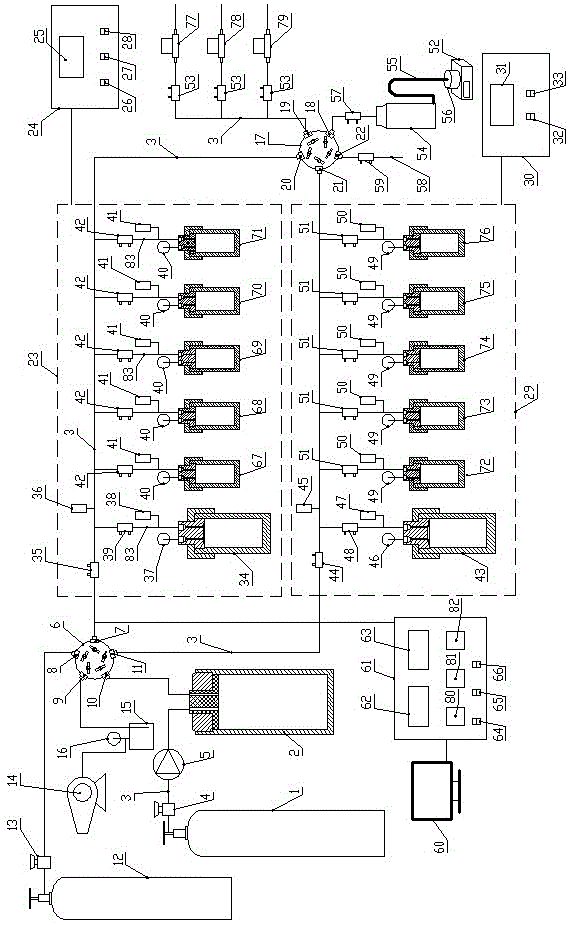

[0033] Such as figure 1 As shown, the high-low temperature and high-pressure adsorption and desorption test device of the present invention includes an air charging system, a degassing system, an adsorption system, a desorption system, a temperature control system and a data acquisition system.

[0034] The charging system includes a methane charging unit and a helium charging unit. The methane charging unit includes a high-pressure methane gas cylinder 1, a methane gas storage tank 2 and the first five-way valve. 3 connected, the high-pressure pipe 3 between the high-pressure methane gas cylinder 1 and the methane gas storage tank 2 is sequentially provided with a first gas pressure reducing valve 4 and a high-pressure gas booster pump 5 in series along the flow direction of methane gas, and the first five-way valve Including the first valve body 6, the first valve body 6 is provided with a first port 7, a second port 8, a third port 9, a fourth port 10 and a fifth port 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com