Optimization method for balancing loads of multiple chip mounters in assembly line in PCB assembling technology

A PCB board and load balancing technology, applied to biological models, instruments, manufacturing computing systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

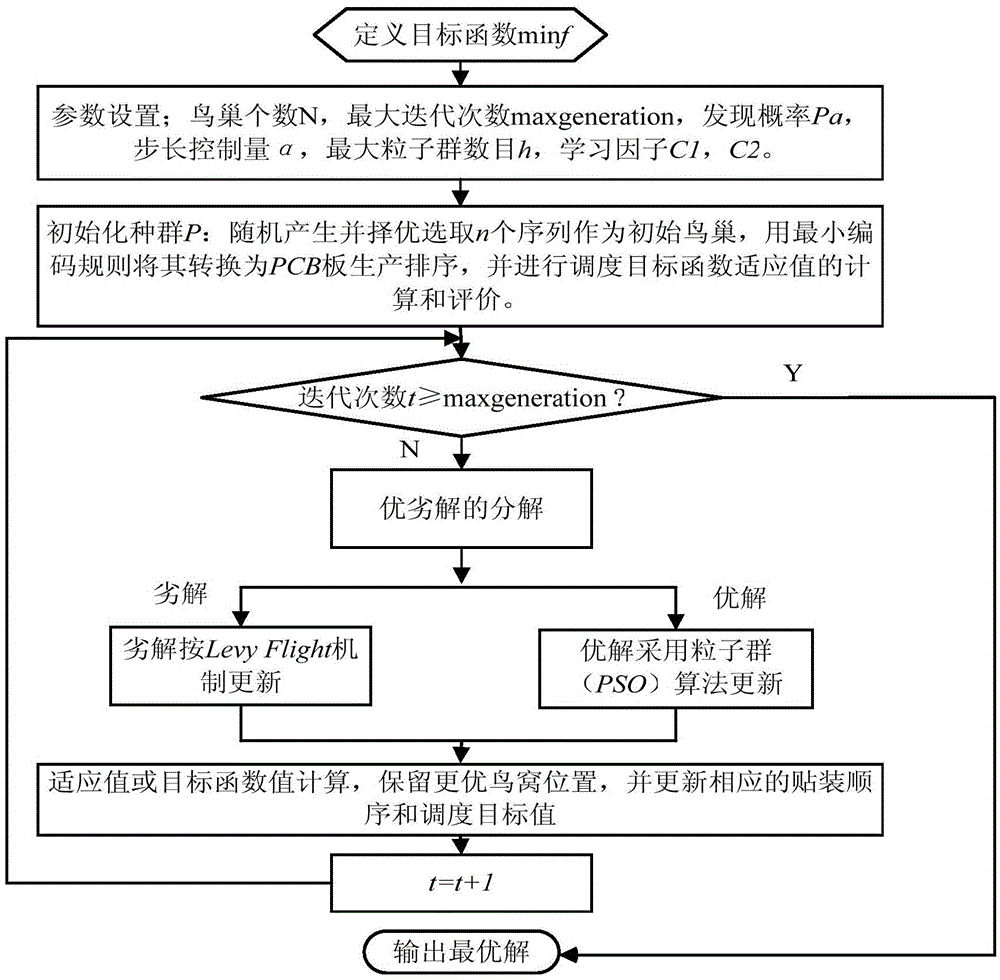

Method used

Image

Examples

Embodiment 1

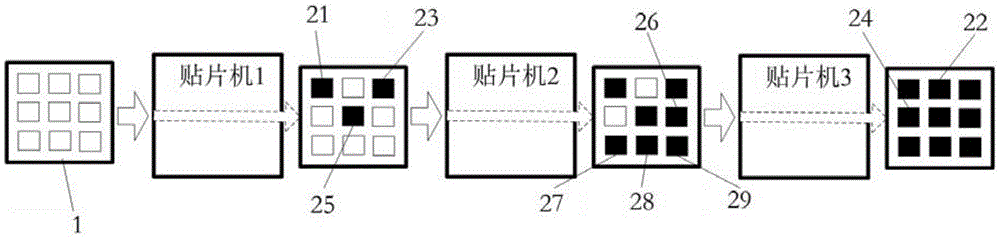

[0059] as attached figure 1 , 1 is PCB board, 21 is component 1, 22 is component 2, 23 is component 3, 24 is component 4, 25 is component 5, 26 is component 6, 27 is component 7, 28 is component 8, 29 is component 9. In the scheduling optimization method of the surface assembly production line placement machine load balance optimization based on the improved cuckoo algorithm of the present invention, the characteristics of the assembly line are: the distribution of PCB boards is carried out by type, and the PCB boards of the same type The processing is usually completed on one placement machine; the assembly task of each component is completed by all the placement machines on the production line, and the processing tasks of each placement machine are completely different;

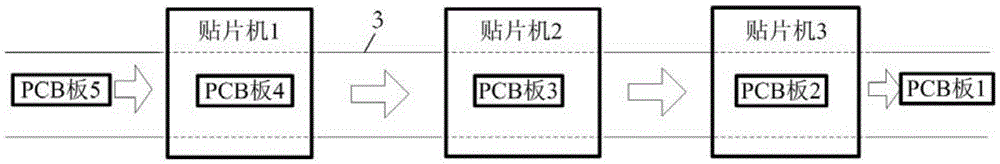

[0060] as attached figure 2 , and 3 is a conveyor belt. In the scheduling optimization method of the surface assembly production line mounter load balance optimization based on the improved cuckoo algorit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com