Grain-compounded soybean protein snack dried bean curd and preparation method thereof

A technology of soybean protein and soybean protein isolate, which is applied in the field of grain compound soybean protein leisure dried tofu and its preparation, can solve the problems of poor moisture control, poor product taste, single variety, etc., and achieve low cost, simple processing, and simple formula Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 Sweet corn leisure dried tofu

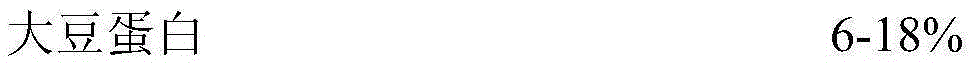

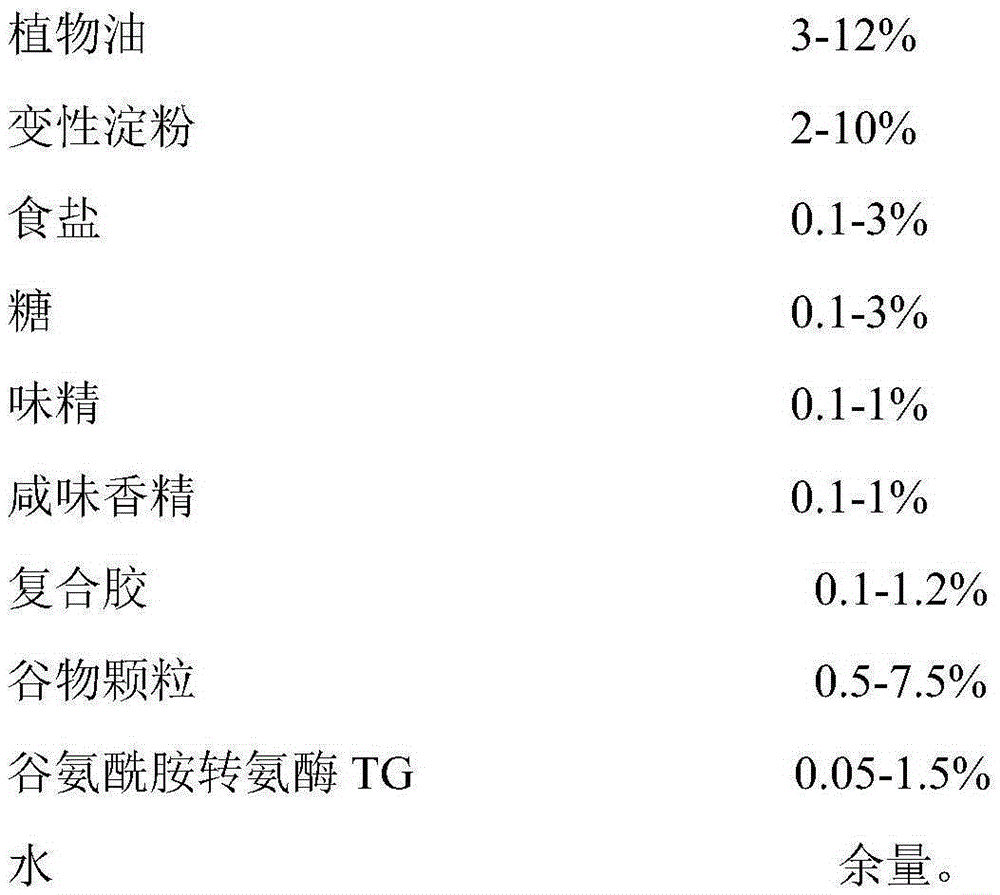

[0042]

[0043]

[0044] a) Pretreatment of grain granules: Wash the prepared grain granules with clean water to remove bad and moldy granules, soak for 1 hour, and set aside.

[0045] b) Mix protein, water and oil: Add soy protein isolate and ice water to the chopping pot and mix for 3 minutes at 2600r / min, then add vegetable oil and mix for 1min at 3500r / min

[0046] c) Mixing of auxiliary materials: Add modified starch, compound gum, salty flavor and seasoning to the emulsified product prepared in step b), turn and chop at 3500r / min for 3min, then add grain granules and transglutaminase, 100r / min turn chopping and stir for 1min.

[0047] d) Refrigeration reaction: put it in a freezer at 0-4°C and refrigerate for 10 hours

[0048] e) Slicing and marinating: put the raw material obtained in step d) into a slicer, cut into rectangular blocks of 4cm×2cm×50mm, put it in brine and marinate for 30min, and the temperature of...

Embodiment 2

[0051] Example 2 Marinated Green Bean Leisure Dried Tofu

[0052]

[0053]

[0054] a) Pretreatment of grain granules: Wash the prepared grain granules with clean water to remove bad and moldy granules, soak for 1 hour, and set aside.

[0055] b) Mix protein, water and oil: Add soy protein isolate and ice water to the chopping pot and chop for 4 minutes at 2600r / min, then add vegetable oil and chop for 2min at 3500r / min

[0056] c) Mixing of auxiliary materials: Add modified starch, compound gum, salty flavor and seasoning to the emulsified product prepared in step b), turn and chop at 3500r / min for 2.5min, then add cereal granules and transglutaminase, 200r / min, chop and mix for 1min.

[0057] d) Refrigeration reaction: put it in a freezer at 0-4°C and refrigerate for 12 hours

[0058] e) Slicing and marinating: Put the raw material prepared in step d) into a slicer, cut into rectangular blocks of 4cm×2cm×50mm, put it in brine and marinate for 55min, and the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com