A preparation method of porous polymeric ionic liquid for carbon dioxide adsorption

A technology for polymerizing ionic liquids and carbon dioxide, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as small interface area, hindering industrial applications, unfavorable gas dissolution and diffusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

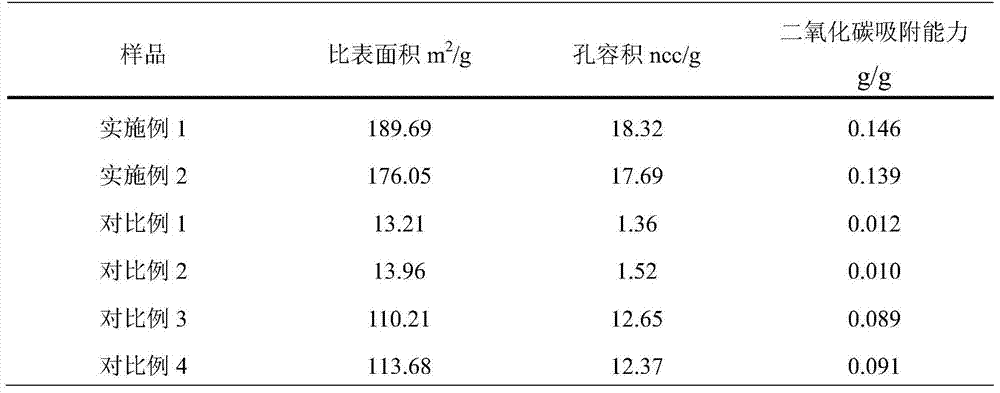

Examples

Embodiment 1

[0015] Example 1: Get 3g of 1-vinyl-3-butylimidazolium hydroxide (about 0.01mol), 2.36g of divinylbenzene (55%, about 0.01mol) and 0.00536g of initiator azobisiso Butyronitrile In a 100ml three-neck flask, add 50ml of a mixed solution of ethanol and water as a solvent (the volume ratio of ethanol and water is 1:1). During the reaction, CO was passed through the three-necked flask 2 gas, heated to 60°C for polymerization, and the reaction was maintained for 6 hours. After the reaction is over, vacuum filter the product to remove the solvent, wash it three times with absolute ethanol and deionized water, then place it in a vacuum freezer, use liquid nitrogen as the coolant, and carry out vacuum sublimation at minus 80°C. It is 3kPa, and the treatment time is 24 hours, and a white solid powder is obtained, which is a porous polymeric ionic liquid.

Embodiment 2

[0016] Embodiment 2: Get 3g of 1-vinyl-3-butylimidazolium hydroxide (about 0.01mol), 2.36g of divinylbenzene (55%, about 0.01mol) and 0.0536g of initiator azobisiso Butyronitrile In a 100ml three-necked flask, add 50ml of a mixed solution of ethanol and water as a solvent (the volume ratio of ethanol and water is 3:1). During the reaction, CO was passed through the three-necked flask 2 gas, heated to 100°C for polymerization, and the reaction was maintained for 6 hours. After the reaction is over, vacuum filter the product to remove the solvent, wash it three times with absolute ethanol and deionized water, then place it in a vacuum freezer, use liquid nitrogen as the coolant, and carry out vacuum sublimation at minus 100°C. It is 5kPa, and the treatment time is 48 hours, and a white solid powder is obtained, which is a porous polymeric ionic liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com