Photocatalytic material, and preparation method and application thereof

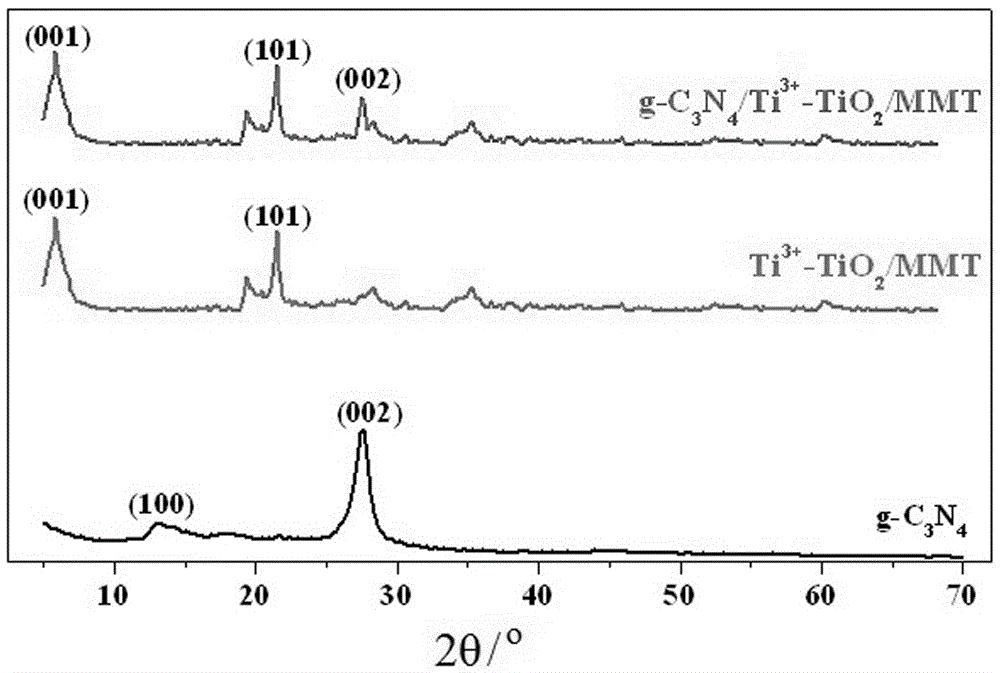

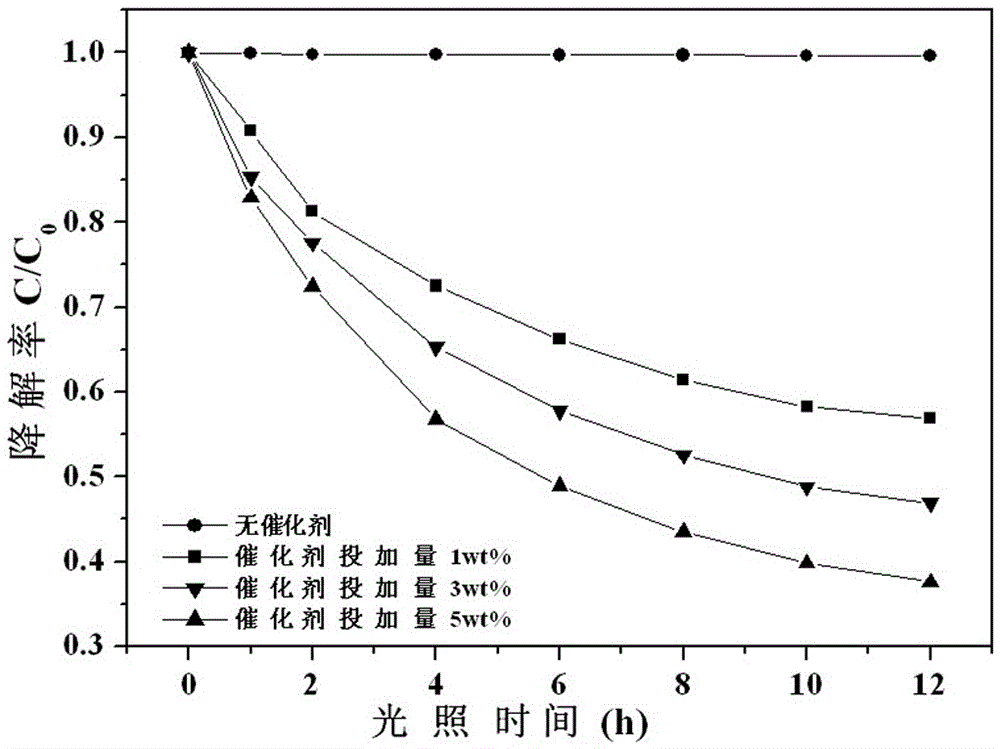

A photocatalytic material, g-c3n4 technology, applied in chemical instruments and methods, applications, soil conditioning materials, etc., can solve the problem of high photo-generated electron-hole pair recombination rate, unsatisfactory visible light photocatalytic activity, and low solar energy utilization. and other problems, to achieve the effect of increasing the photoresponse range, improving the photocatalytic degradation reaction activity, and having a good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

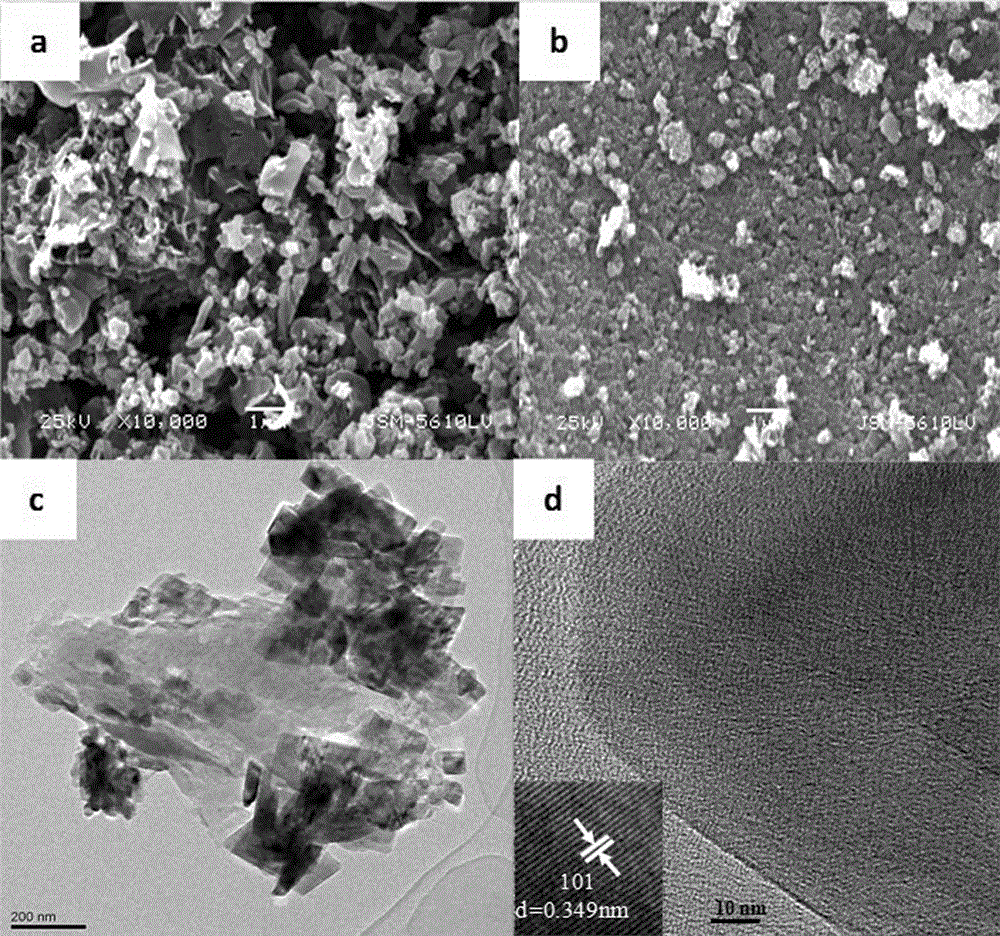

[0043] g-C with visible light response 3 N 4 / Ti 3+ -TiO 2 The preparation method of / montmorillonite composite photocatalytic material, it comprises the steps:

[0044] 1) Weigh 20g of urea powder into an alumina crucible, cover it with a lid, and place it in a muffle furnace. Then it was heated to 520° C. at a heating rate of 5° C. / min for 4 hours. When the temperature dropped to room temperature, it was taken out to obtain light yellow g-C 3 N 4 powder;

[0045] 2) Add 25ml TiCl to a reaction kettle with a volume of 100ml 3 solution (commercially available, mass fraction 16-18%, the same below) and 15ml of deionized water, then add 3.5ml of HF solution (40wt%) dropwise, after stirring at room temperature for 15min, seal the reaction kettle and transfer it to a constant temperature blasting In a drying oven, keep it at 200°C for 12 hours. After it cools down naturally, take out the precipitate in the reaction kettle and centrifuge it. After washing with deionized wate...

Embodiment 2

[0052] g-C with visible light response 3 N 4 / Ti 3+ -TiO 2 The preparation method of / montmorillonite composite photocatalytic material, it comprises the steps:

[0053] 1) Weigh 20g of urea powder into an alumina crucible, cover it with a lid, and place it in a muffle furnace. Then it was heated to 520° C. at a heating rate of 5° C. / min for 4 hours. When the temperature dropped to room temperature, it was taken out to obtain light yellow g-C 3 N 4 powder;

[0054] 2) Add 25ml TiCl to a reaction kettle with a volume of 100ml 3 solution and 15ml of deionized water, and then add 3.5ml of HF solution (40wt%) dropwise, after stirring at room temperature for 15min, seal the reaction kettle and transfer it to a constant temperature blast drying oven, keep it at 200°C for 12h, and wait for After natural cooling, take out the precipitate in the reaction kettle and centrifuge, wash with deionized water for 3 times, dissolve in 10ml absolute ethanol solution, and add it dropwise ...

Embodiment 3

[0058] g-C with visible light photocatalytic activity 3 N 4 / Ti 3+ -TiO 2 The preparation method of / montmorillonite composite photocatalytic material, it comprises the steps:

[0059] 1) Weigh 20g of urea powder into an alumina crucible, cover it with a lid, and place it in a muffle furnace. Then it was heated to 520° C. at a heating rate of 5° C. / min for 4 hours. When the temperature dropped to room temperature, it was taken out to obtain light yellow g-C 3 N 4 powder;

[0060] 2) Add 25ml of TiCl3 solution and 15ml of deionized water to a reaction kettle with a volume of 100ml, then add 3.5ml of HF solution (40wt%) dropwise, stir at room temperature for 15min, seal the reaction kettle and transfer it to a constant temperature blast drying oven Keep it at 200°C for 12 hours, take out the precipitate in the reactor after it cools naturally, and centrifuge it, wash it with deionized water for 3 times, dissolve it in 10ml of absolute ethanol solution, and add it dropwise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com