LED (Light Emitting Diode) light-emitting laminated glass and preparations method of LED light-emitting laminated glass

A technology of luminous interlayer and LED lamps, which is applied in chemical instruments and methods, glass/slag layered products, lamination, etc., can solve the problems of poor heat insulation effect of luminous glass, achieve enhanced heat insulation effect, and avoid heat loss. The effect of exchanging and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

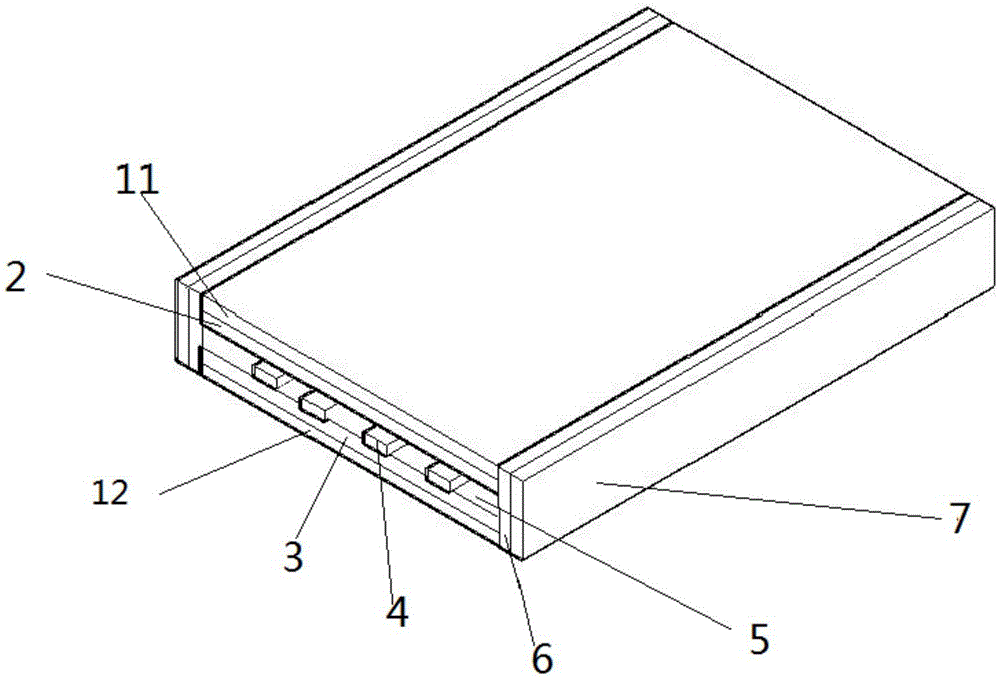

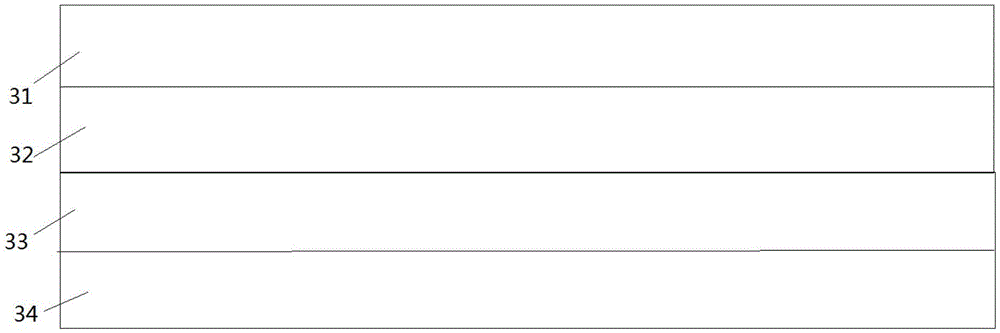

[0018] refer to Figure 1~Figure 2 , a kind of LED light-emitting laminated glass and its preparation method provided by the present invention, comprising: a glass layer, including: a first glass layer 11 and a second glass layer 12 stacked from top to bottom; a conductive layer 2 arranged on the The upper surface of the second glass layer 12 is engraved with a circuit groove; the LED lamp 4 is pasted on the circuit groove through conductive silver glue; the interlayer 5 is coated on the upper surface of the conductive layer; the infrared reflection Layer 3 is arranged on the upper surface of the interlayer 5, and the first glass layer 11 is arranged on the upper surface; the sealing layer 6 is coated around the glass layer along the direction perpendicular to the glass layer; the protective layer 7 is longitudinally coated on the gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com