VCI (volatile corrosion inhibitor) powder metallic finishing coating and preparation method thereof

A powder metal and topcoat technology, used in powder coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems of harsh construction environment, increase project cost, and high cost of wastewater treatment, achieve outstanding anti-rust performance, reduce dispersion speed, Anti-rust effect Comprehensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

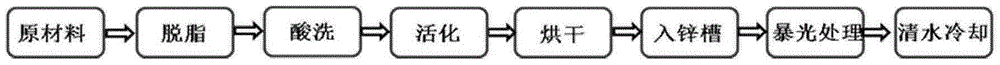

Method used

Image

Examples

Embodiment 1

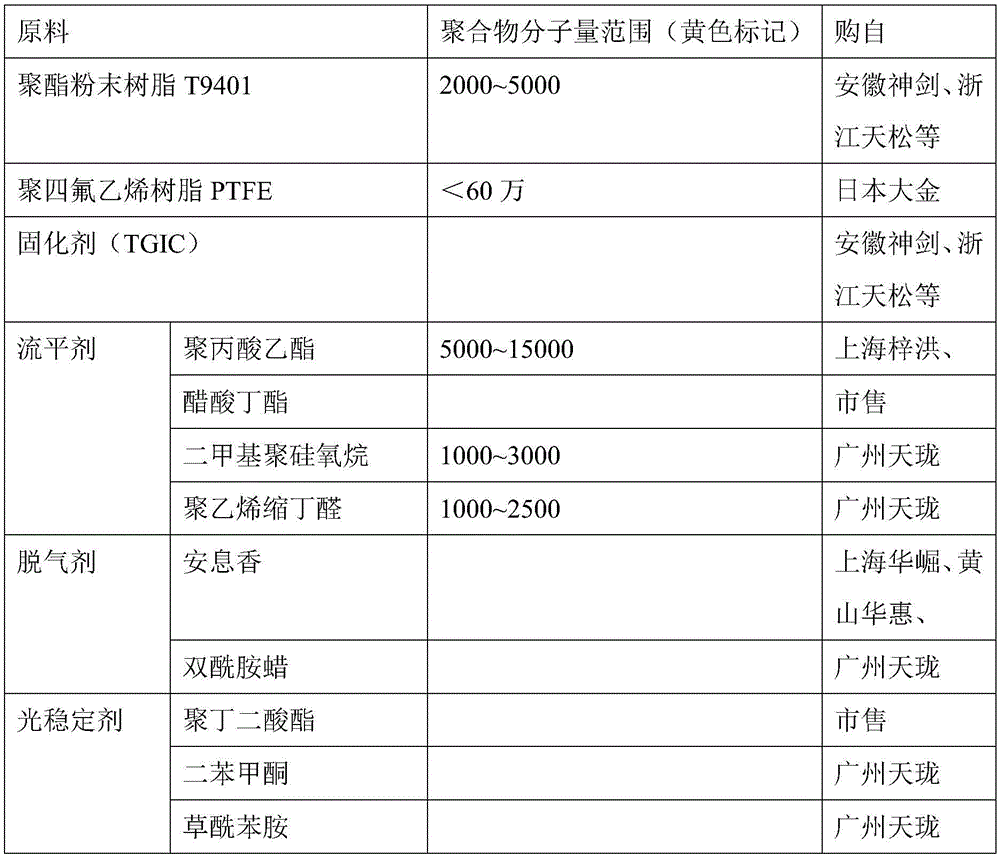

[0046] VCI powder metal finish paint, comprises the component of following parts by weight: comprises base material, filler, VCI vapor phase corrosion inhibitor and auxiliary agent; Described base material comprises 30 parts of polyester powder resins, 15 parts of polytetrafluoroethylene resins, 3 parts of curing agent (TGIC); the filler includes 1 part of flake aluminum powder or pearl powder, 40 parts of barium sulfate; the auxiliary agent is one of leveling agent, conductive agent, degassing agent, and light stabilizer or several; the mass ratio of the base material to the filler is 3:1; the quality of the VCI vapor phase corrosion inhibitor is 10% of the total mass of the base material and the filler; the quality of the auxiliary agent is the total mass of the base material and the filler 2% of mass.

[0047] The leveling agent is polyethyl propionate, butyl acetate, dimethyl polysiloxane, polyvinyl butyral; the conductive agent is graphite or amorphous carbon black; the d...

Embodiment 2

[0056] VCI powder metal topcoat paint, comprises the component of following parts by weight: comprises base material, filler, VCI vapor phase corrosion inhibitor and auxiliary agent; Described base material comprises 50 parts of polyester powder resins, 5 parts of polytetrafluoroethylene resins, 5 parts of curing agent (TGIC); the filler includes 5 parts of flaky aluminum powder or pearl powder, 20 parts of barium sulfate; the auxiliary agent is one of leveling agent, conductive agent, degassing agent, and light stabilizer or several; the mass ratio of the base material to the filler is 2:3; the quality of the VCI vapor phase corrosion inhibitor is 5% of the total mass of the base material and the filler; the quality of the auxiliary agent is the total mass of the base material and the filler. 10% of the mass.

[0057] The leveling agent is polyethyl propionate, butyl acetate, dimethyl polysiloxane, polyvinyl butyral; the conductive agent is graphite or amorphous carbon black;...

Embodiment 3

[0066] VCI powder metal finish paint, comprises the component of following parts by weight: comprises base material, filler, VCI vapor phase corrosion inhibitor and auxiliary agent; Described base material comprises 40 parts of polyester powder resins, 10 parts of polytetrafluoroethylene resins, 4 parts of curing agent (TGIC); the filler includes 3 parts of flake aluminum powder or pearl powder, 30 parts of barium sulfate; the auxiliary agent is one of leveling agent, conductive agent, degassing agent, and light stabilizer or several; the mass ratio of the base material and the filler is 1:1; the quality of the VCI vapor phase corrosion inhibitor is 7% of the total mass of the base material and the filler; the quality of the auxiliary agent is the total mass of the base material and the filler. 6% of mass.

[0067] The leveling agent is polyethyl propionate, butyl acetate, dimethyl polysiloxane, polyvinyl butyral; the conductive agent is graphite or amorphous carbon black; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com