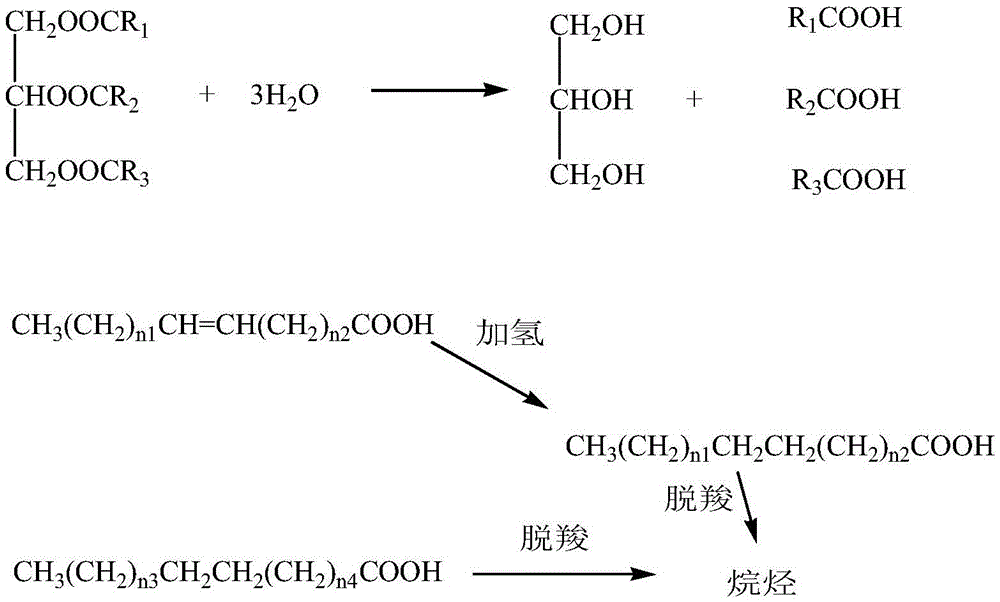

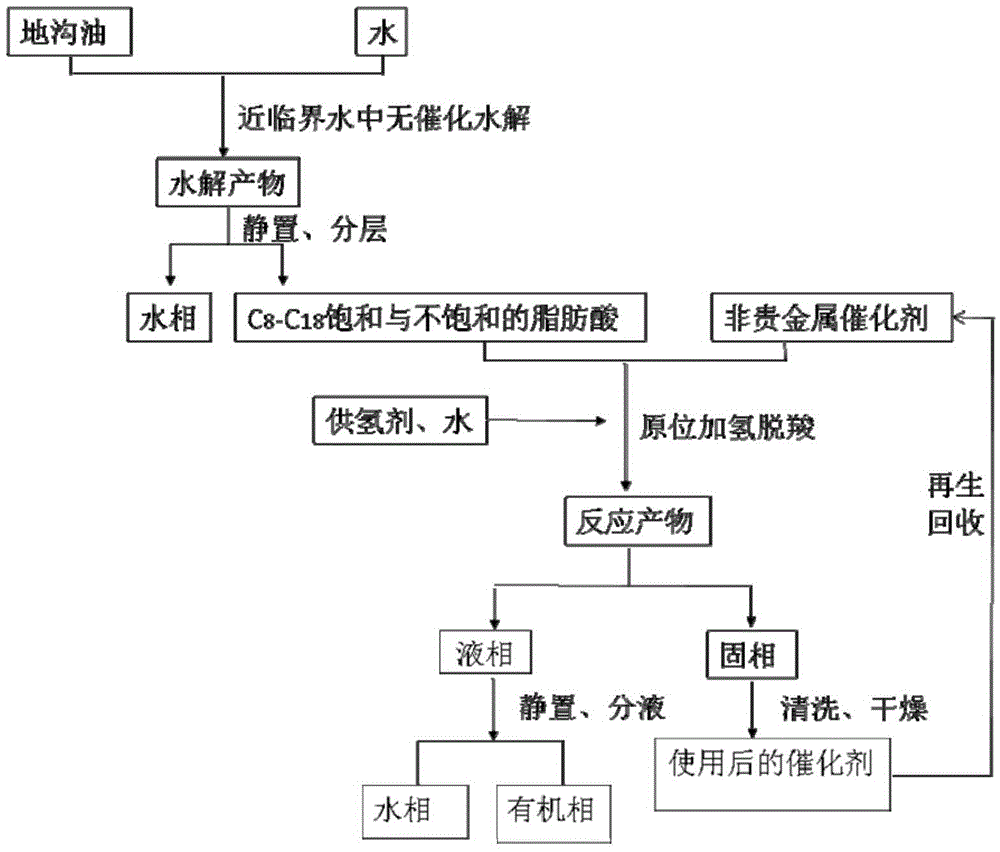

Method for preparing long-chain alkane from gutter oil through hydrolysis and in-situ hydrogenation and decarboxylation

An in-situ hydrogenation and long-chain alkane technology, which is applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, biological raw materials, etc., can solve the problems that need to be further improved, the total mass yield of the three-step reaction is low, etc., and the product separation is convenient. , easy separation, zero hydrogen consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

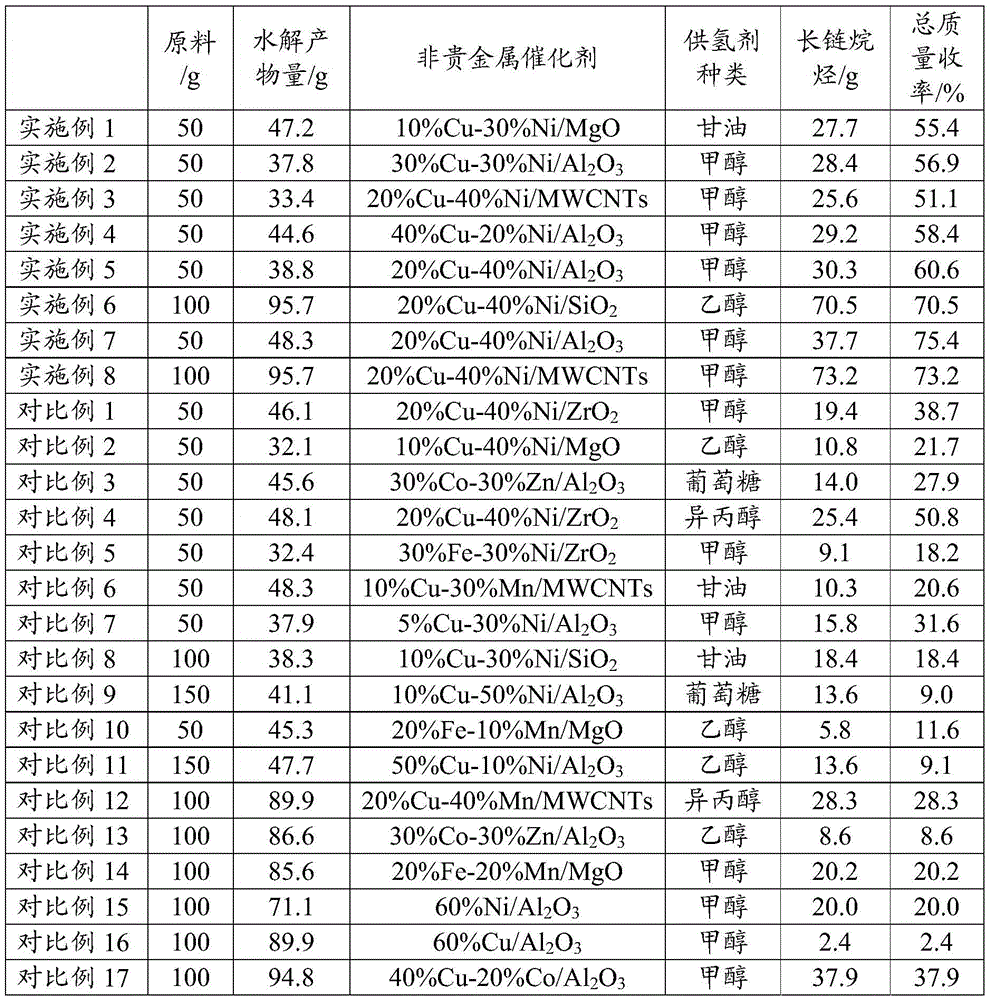

Embodiment 1

[0040] Add 50g waste oil and 50g deionized water into a 500mL intermittent high-temperature and high-pressure reactor, start stirring, heat up to 230 ° C for 10 hours of hydrolysis reaction, after the hydrolysis reaction is completed, cool to room temperature, and obtain the upper hydrolyzate (C 8 ~C 18 fatty acid) 47.2g; 47.2g hydrolyzate and 3.8g10%Cu-30%Ni / MgO catalyst, 11.2g glycerol, 210mL deionized water were added to a 500mL intermittent high-temperature and high-pressure reactor, heated to 330°C for 4 hours , after the reaction was completed, the reaction product was cooled and filtered; the liquid phase product was allowed to stand for stratification, and the organic phase was separated and analyzed with GC-FID after constant volume with acetone, and the calculated quality of the long-chain alkane was 27.7g. The total mass yield is 55.4% of the mass of long-chain alkanes divided by the mass of waste oil.

Embodiment 2

[0042] Add 50g waste oil and 50g deionized water into a 500mL intermittent high-temperature and high-pressure reactor, start stirring, heat up to 210°C for hydrolysis reaction for 6h, after the hydrolysis reaction is completed, cool to room temperature, and obtain the upper hydrolyzate (C 8 ~C 18 fatty acid) 37.8g; 37.8g hydrolyzate and 9.5g30%Cu-30%Ni / Al 2 o 3 Catalyst, 13.5g methanol, 250mL deionized water were added to a 500mL intermittent high-temperature and high-pressure reactor, heated to 330°C for 3 hours, and after the reaction was completed, the reaction product was cooled and filtered; the liquid phase product was separated and separated to obtain After the organic phase was fixed to volume with acetone, it was analyzed by GC-FID. The calculated mass of long-chain alkanes was 28.4 g, and the total mass yield of long-chain alkanes was 56.9%.

Embodiment 3

[0044] Add 50 g of waste oil and 100 g of deionized water into a 500 mL intermittent high-temperature and high-pressure reactor, start stirring, heat up to 190 ° C for 7 hours of hydrolysis reaction, after the hydrolysis reaction is completed, cool to room temperature, and obtain the upper hydrolyzate (C 8 ~C 18 fatty acid) 33.4g; 33.4g hydrolyzate and 6.7g20%Cu-40%Ni / MWCNTs catalyst, 15.6g methanol, 210mL deionized water were added to a 500mL intermittent high-temperature and high-pressure reactor, heated to 330°C for 1 hour , after the reaction was completed, the reaction product was cooled and filtered; the liquid phase product was allowed to stand for stratification, and the organic phase was separated and analyzed with GC-FID after constant volume with acetone, and the calculated quality of the long-chain alkane was 25.6g, and the mass of the long-chain alkane The total mass yield is 51.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com