Eccentric wheel type antifriction and resistance-reducing device

A friction and drag reduction, eccentric wheel technology, applied in drilling equipment, earth-moving drilling, drill pipe, etc., can solve the problems of high friction resistance of drill string and difficult feeding of drill string, so as to prolong drilling length and save economic cost. , the effect of reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

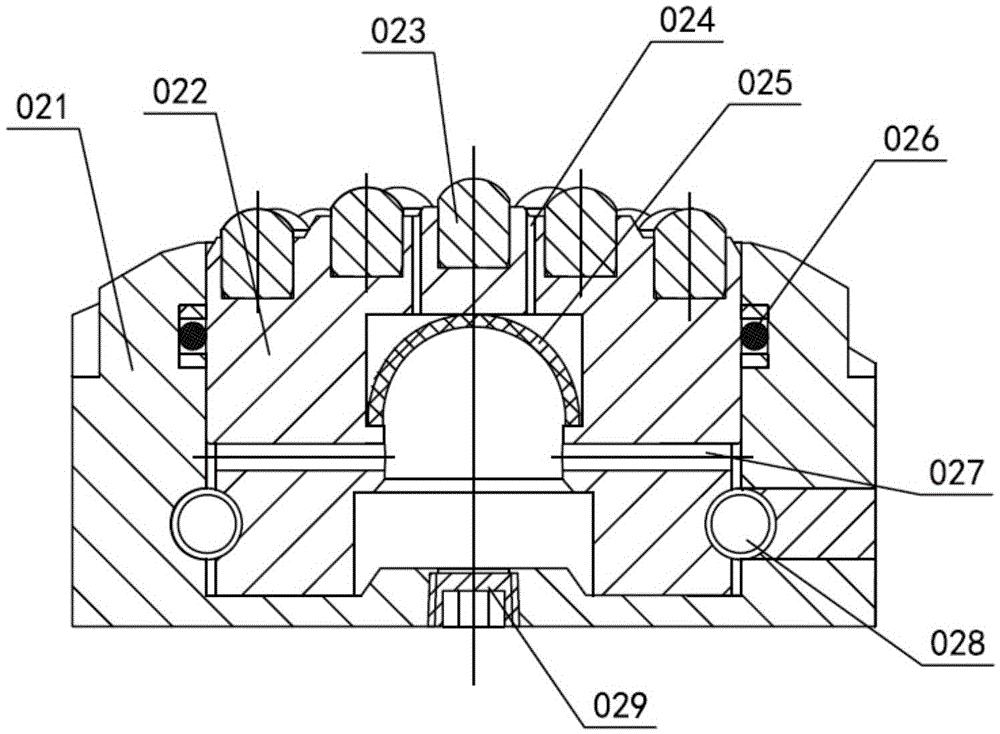

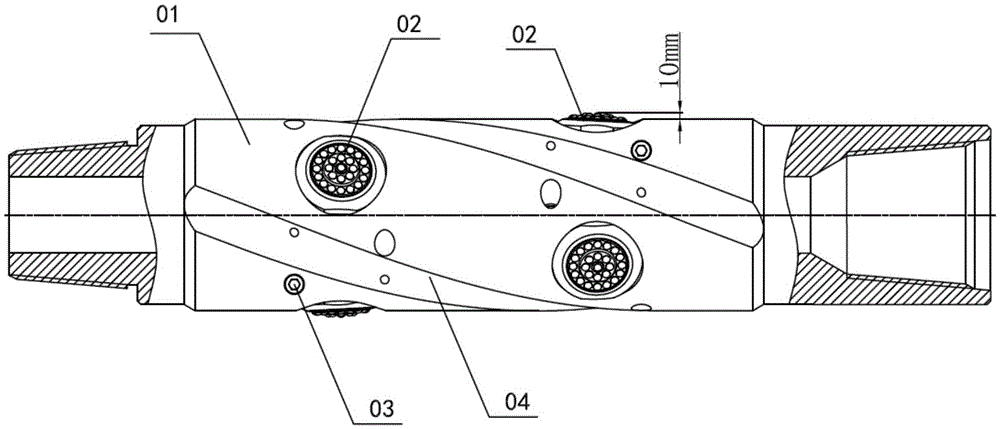

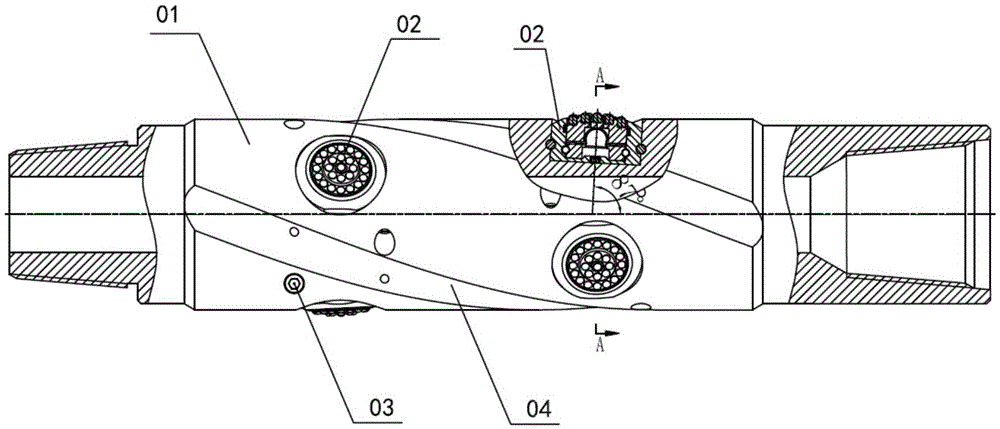

[0040] For the sectional structural diagram of the drag reducing wheel assembly in the eccentric wheel type friction reducing and drag reducing device of the present invention, refer to figure 1, the drag reducing wheel assembly 02 includes a roller cover 021, a roller 022, a plurality of anti-wear teeth 023, and an oil storage bag 025. The roller cover 021 is provided with an inner cavity, the roller cover 021 is fixed on the cylinder 01, and the roller 022 is arranged on the roller In the inner cavity of the sleeve 021, the upper part of the roller 022 is sealed and connected with the roller sleeve 021 through a sealing structure. The through hole is provided with a sealing plug 029; the lower part of the roller 022 is rollingly connected with the roller sleeve 021 through a rolling connection structure, and the lower part of the roller 022 is also pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com