A kind of composite organic expansion agent for negative electrode of lead-acid battery and preparation method thereof

A lead-acid battery and expansion agent technology, applied in lead-acid batteries, battery electrodes, circuits, etc., to achieve the effects of improving battery life, delaying sulfation, and reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Preparation of composite organic expansion agent

[0025] Weigh 1.5g of sodium lignosulfonate and 0.5g of humic acid into a 250mL three-necked bottle, add 100mL of deionized water, and stir for 10min. Add 0.05g of ammonium persulfate, 0.01g of N-N'-methylenebisacrylamide, and 6g of acrylamide in sequence, and react at 40°C for 5 hours to obtain a brown solution. Add 100mL of isopropanol to the solution, and after standing for a certain period of time, the precipitate is separated and washed with ethanol several times to obtain the composite organic expansion agent.

[0026] 2. Material Characterization

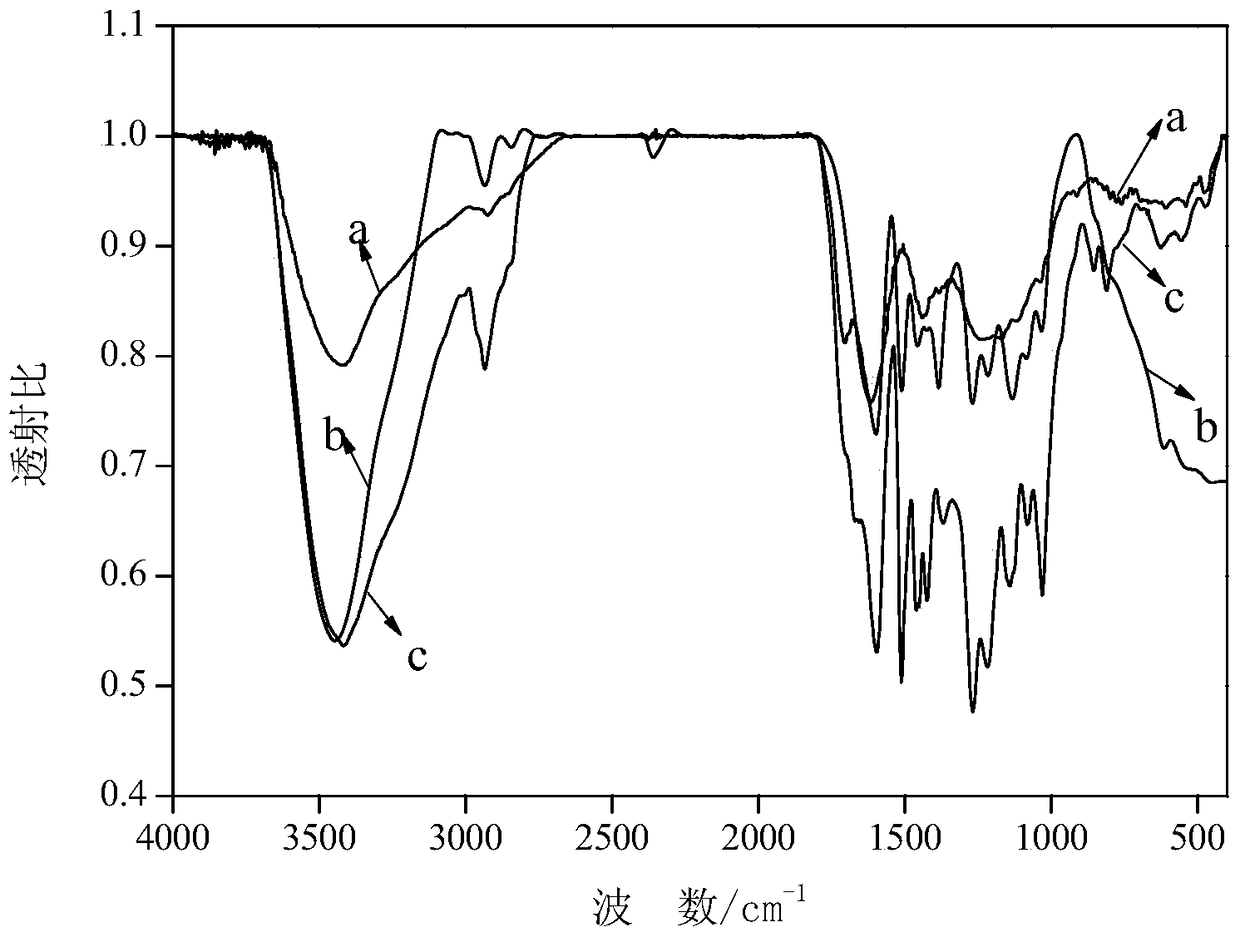

[0027] The humic acid, sodium lignosulfonate and the above composite materials were detected by infrared spectroscopy. The result is as figure 1 As shown, humic acid (a), sodium lignosulfonate (b) and composite material (c) all have absorption in each wavelength range, and the composite material has higher absorption intensity at each wavelength. 3400cm -1 The l...

Embodiment 2

[0042] Weigh 2 g of sodium lignosulfonate and 0.5 g of humic acid into a 250 mL three-necked bottle, add 100 mL of deionized water, and stir for 15 min. Add 0.06g of ammonium persulfate, 0.015g of N-N'-methylenebisacrylamide, and 6.5g of acrylamide in sequence, and react at 45°C for 5 hours to obtain a brown solution. Add 100 mL of isopropanol to the solution, and after standing for a certain period of time, the precipitate is separated and washed several times with ethanol.

Embodiment 3

[0044] Weigh 2.5g of sodium lignosulfonate and 0.7g of humic acid into a 250mL three-necked bottle, add 100mL of deionized water, and stir for 20min. Add 0.07g of ammonium persulfate, 0.02g of N-N'-methylenebisacrylamide, and 7g of acrylamide in sequence, and react at 50°C for 5 hours to obtain a brown solution. Add 100 mL of isopropanol to the solution, and after standing for a certain period of time, the precipitate is separated and washed several times with ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com