Electrolyte additive and high-voltage electrolyte containing same

An electrolyte additive and electrolyte technology, applied in the field of electrolyte additives and high-voltage electrolytes, can solve the problems of poor cycle performance, restricting the development of lithium-ion batteries, and reducing the efficiency of charging and discharging of lithium-ion batteries, so as to improve energy density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of the high-voltage electrolyte additive used is:

[0044] (1) Take a certain amount of acrylic acid and propylene sulfuric anhydride (molar ratio 1:1) and mix them evenly, and reflux at 80°C for 6 hours, and the obtained mixed liquid is purified by rotary steaming at 60°C to obtain a one-step reaction product;

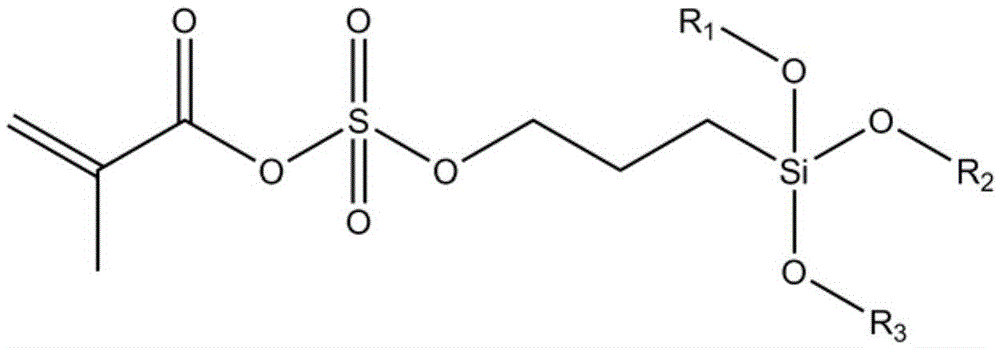

[0045] (2) Add trimethoxysilane (molar ratio 1:1) to the product obtained in (1), add solvent toluene at a volume ratio of 1:10, add 5 mg of platinum as a hydrosilylation reaction catalyst, and reflux at 60°C 6h, the obtained liquid was removed by rotary evaporation at 80°C to obtain R 1 , R 2 , R 3 Both are methyl structures;

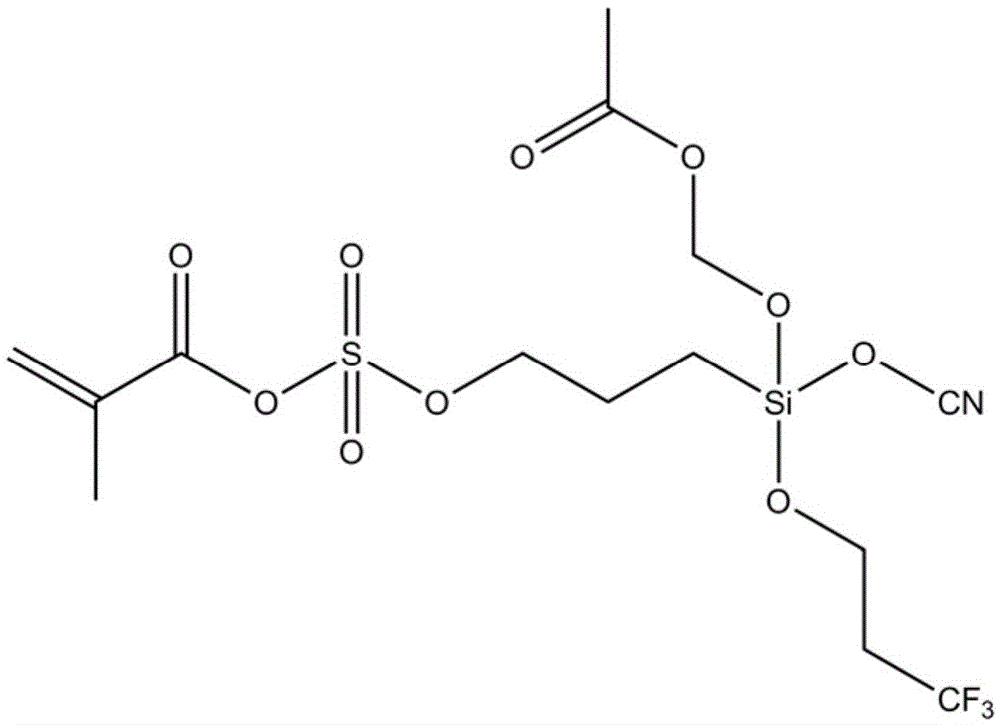

[0046] (3) mix (2) obtained substance with NC-OH, F 3 C-CH 2 CH 2 -OH, CH 3 COOCH 2 -OH is mixed evenly (molar ratio 1:1:1:1), solvent toluene is added at a volume ratio of 1:10, refluxed at 80°C for 2-4h to remove methanol, and the resulting mixture is purified by rotary evaporation at 60°C to obtain the ...

Embodiment 2

[0051] The preparation method of the high-voltage electrolyte additive used is:

[0052] (1) Take a certain amount of acrylic acid and propylene sulfuric anhydride (molar ratio 1:1), mix and stir evenly, reflux at 90°C for 7 hours, and the obtained mixed liquid is purified by rotary steaming at 60°C to obtain a one-step reaction product;

[0053] (2) Add trimethoxysilane (molar ratio 1:1) to the product obtained in (1), add solvent toluene at a volume ratio of 1:10, add 5 mg of platinum as a hydrosilylation reaction catalyst, and reflux at 40°C 6h, the obtained liquid was removed by rotary evaporation at 80°C to obtain R 1 , R 2 , R 3 Both are methyl structures;

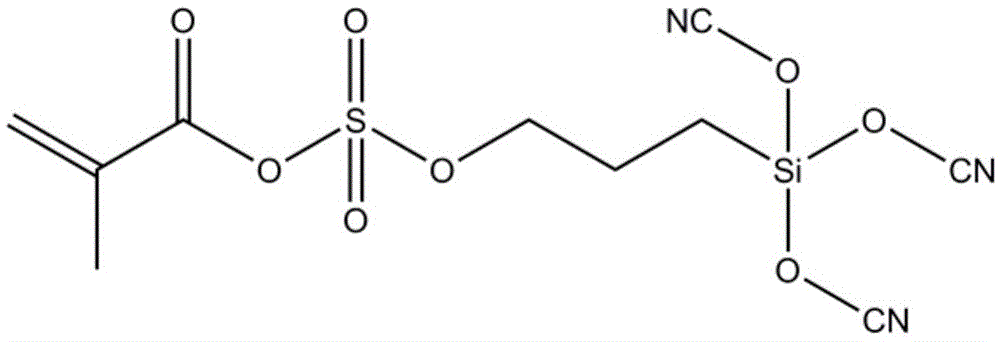

[0054] (3) Mix the substance obtained in (2) with NC-OH (molar ratio 1:3), add the solvent toluene at a volume ratio of 1:10, reflux at 80°C for 2h to remove methanol, and rotate the obtained mixture at 60°C Purification, the desired additives can be obtained.

[0055] Add 0.5% of the total weight of the electro...

Embodiment 3

[0059] The preparation method of the high-voltage electrolyte additive used is:

[0060] (1) Take a certain amount of acrylic acid and propylene sulfuric anhydride (molar ratio 1:1) and mix them evenly, and reflux at 80°C for 8 hours, and the obtained mixed liquid is purified by rotary steaming at 60°C to obtain a one-step reaction product;

[0061] (2) Add trimethoxysilane (molar ratio 1:1) to the product obtained in (1), add solvent toluene at a volume ratio of 1:10, add 5 mg of platinum as a hydrosilylation reaction catalyst, and reflux at 80°C 6h, the obtained liquid was removed by rotary evaporation at 80°C to obtain R 1 , R 2 , R 3 Both are methyl structures;

[0062] (3) Combine the substance obtained in (2) with CH 3 COOCH 2 -OH mixed evenly (molar ratio 1:3), adding solvent toluene at a volume ratio of 1:10, refluxed at 100°C for 3h for dehydration, and rotary steamed and purified the obtained mixture at 80°C to obtain the desired additive.

[0063] Add 0.05% of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Oxidation potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com