Direct torque control system and method for improving motor torque performance

A direct torque control, motor torque technology, applied in control systems, motor control, vector control systems, etc., can solve problems such as large current and torque ripple, asymmetric flux linkage control, complex algorithms, etc., to reduce Effects of torque and current ripple, improved accuracy, and faster system response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

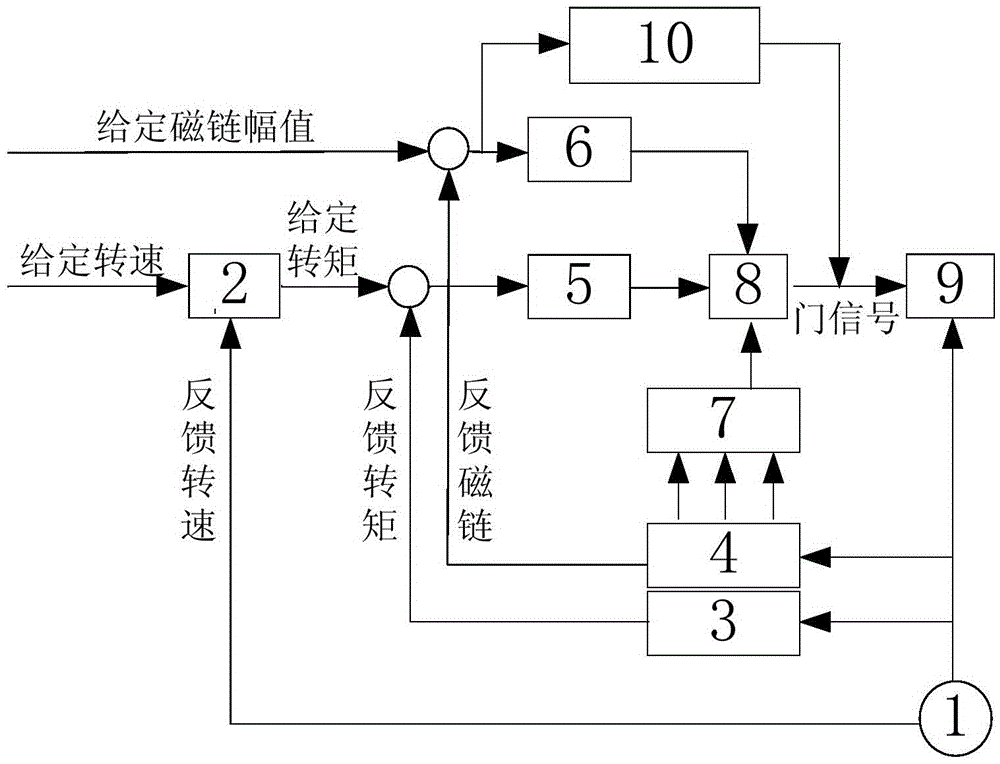

[0019] refer to figure 1 , the direct torque control system of improving motor torque performance described in the present invention comprises torque regulator 5, flux regulator 6, rotational speed regulator 2, sector judging module 7, voltage vector selection table generation module 8, drive Signal generating system 9, duty cycle calculation module 10, flux observer 4 for obtaining stator flux information of motor 1, torque observer 3 for obtaining electromagnetic torque information of motor 1, and motor 1 for obtaining The speed observer of the output shaft speed; the output end of the speed observer is connected to the input end of the speed regulator 2, the output end of the torque observer 3 and the output end of the speed regulator 2 are connected to the input end of the torque regulator 5 The output end of the flux linkage observer 4 is connected with the input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com