Blow-by gas treatment device for internal combustion engine

一种处理装置、内燃机的技术,应用在燃烧空气/燃烧-空气处理、内燃活塞发动机、燃烧发动机等方向,能够解决吸入空气量测量误差等问题,达到降低测量误差、抑制压力脉动的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, an embodiment of the present invention will be described in detail based on the drawings.

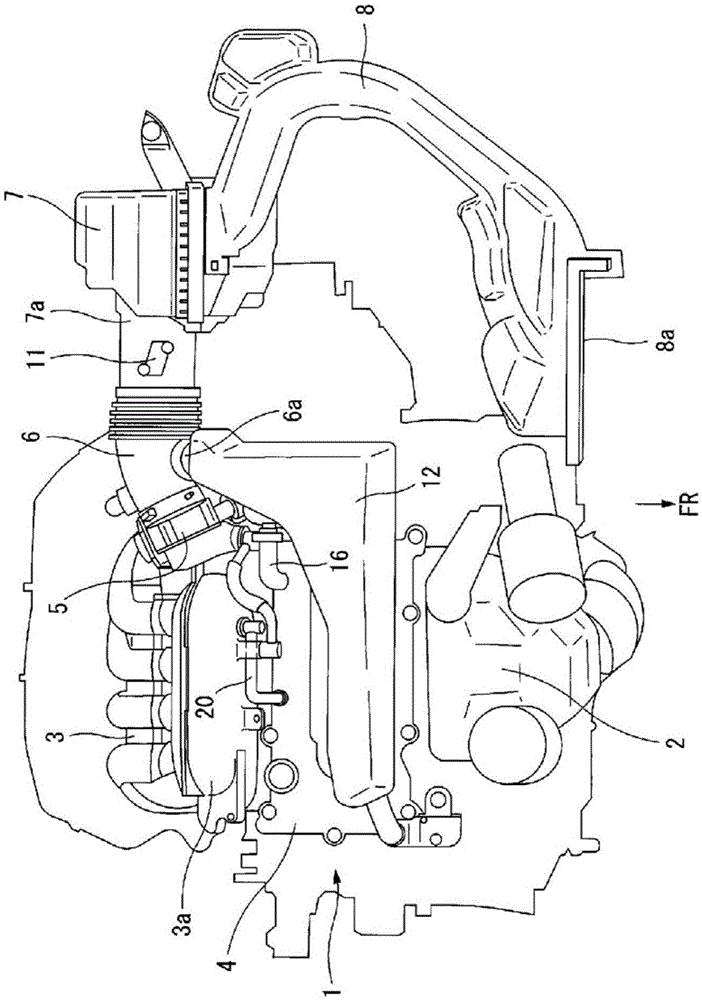

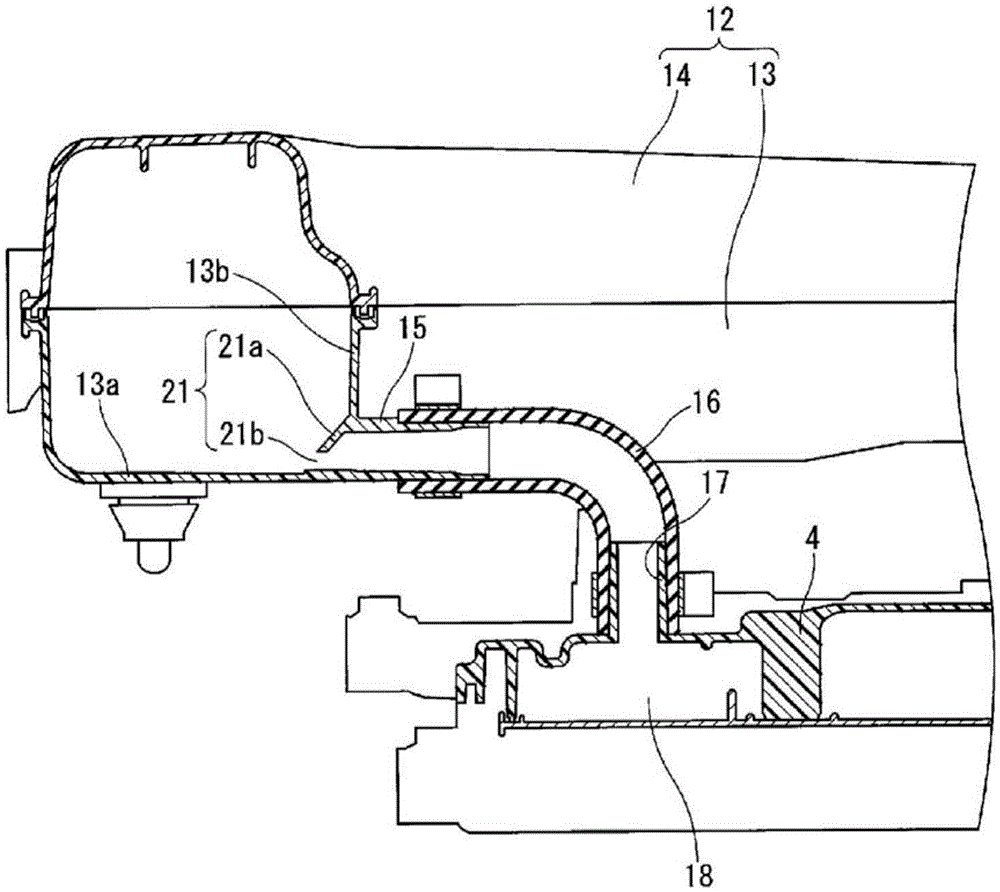

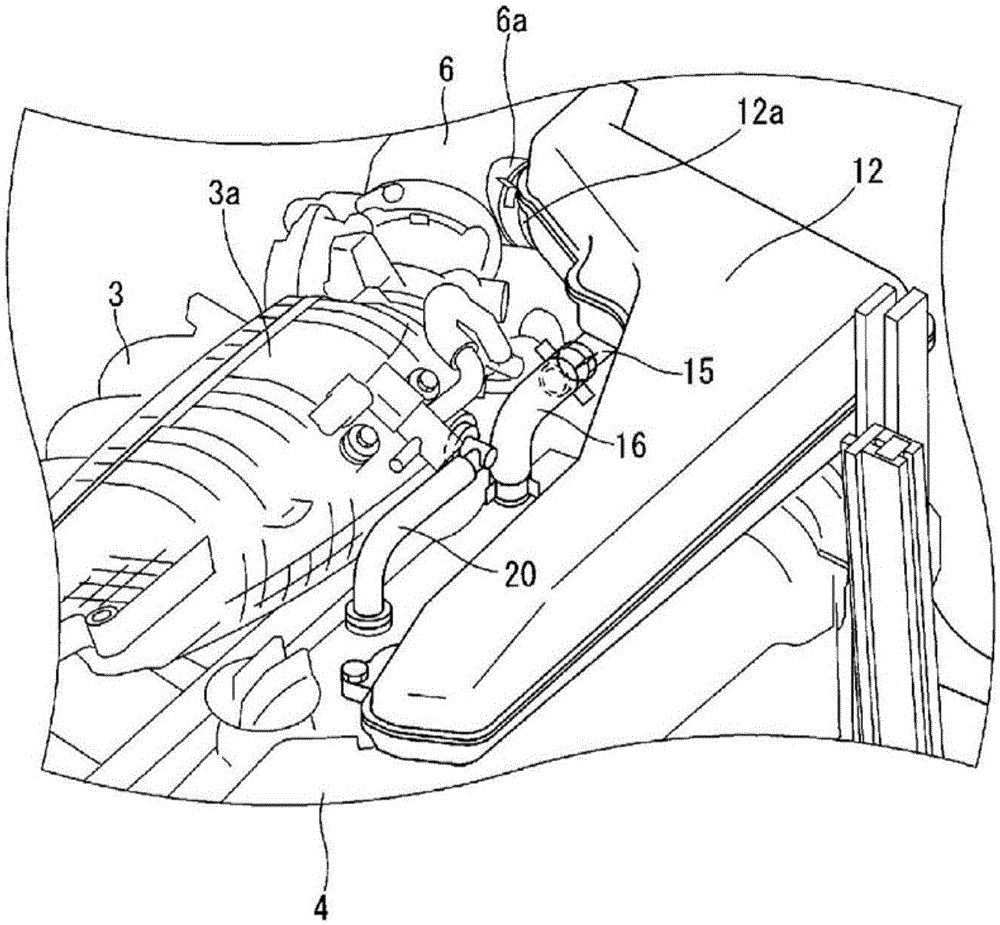

[0018] figure 1 It is a plan view showing an automotive internal combustion engine 1 including an intake system and having a blow-by gas treatment device according to the present invention. The internal combustion engine 1 is mounted in an engine compartment at the front of the vehicle in a so-called transverse position (arrangement in which the central axis of the crankshaft extends in the vehicle width direction), and the exhaust manifold 2 is located on the front side of the vehicle (indicated by reference numeral FR in the figure). The intake manifold 3 is located on the rear side of the vehicle. A header portion 3a forming a part of the intake manifold 3 is disposed adjacent to the cylinder head cover 4 on the vehicle rear side of the cylinder head cover 4, and the throttle chamber 5 is connected to an inlet at one end of the header portion 3a in the longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com