Circulating fluidized bed with semi-conical descending section

A circulating fluidized bed and semi-conical technology, applied in the field of circulating fluidized bed, can solve the problems of throttling, unstable fluidization, inability to eliminate throttling, and affecting the long-term stable operation of industrial devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

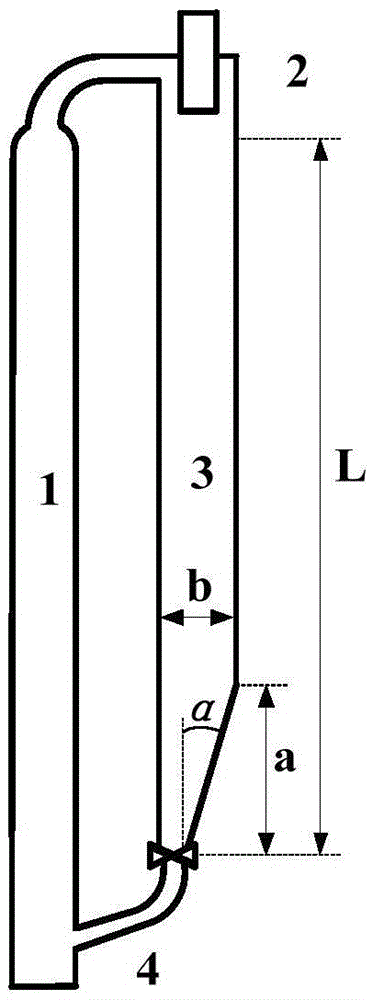

[0020] like figure 1 As shown, a semi-conical descending circulating fluidized bed of the present invention includes a lifting section 1, a cyclone separation section 2, a semi-conical descending section 3, and a particle circulation section 4. The preferred semi-conical structure in Example 1 meets the following conditions: the semi-conical structure is narrow at the bottom and wide at the top, the ratio of the upper and lower widths is 4, the ratio of the height b of the semi-cone to the height L of the descending section is 0.2, and the conical structure of the semi-cone is 0.2. The angle α is 50°, and the distance between the starting position of the semi-conical bottom and the bottom of the descending section is 0. The superficial velocity of circulating gas at the bottom of the lift section is 7.86m / s.

[0021] Figure 4 (a) and (b) are the velocity vector diagrams of gas phase and particle phase in the descending section of this embodiment under the state of a large a...

Embodiment 2

[0023] Embodiment 2 (comparative example):

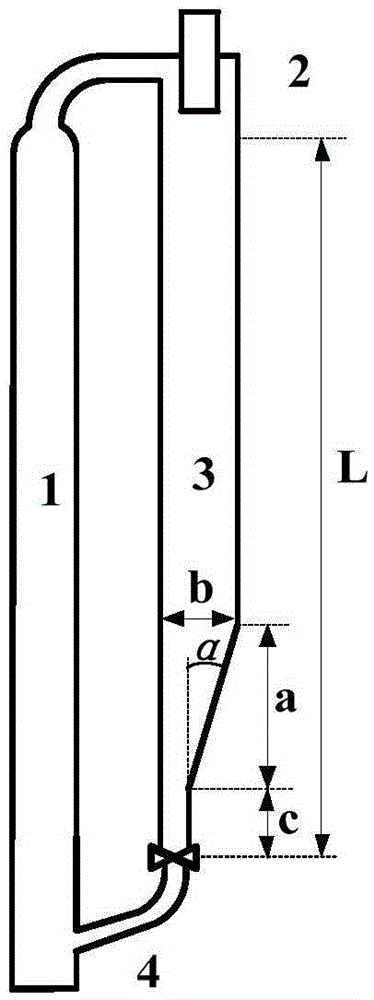

[0024] like figure 2 As shown, the descending section is an axisymmetrically distributed circulating fluidized bed, including a lifting section 1, a cyclone separation section 2, a descending section 3, and a particle circulation section 4. The superficial gas velocity at the bottom of the lifting section is 7.86m / s. Figure 6 It is the variation of particle phase concentration distribution with time when the descending section of this example is in a state of a large amount of blow-by gas. Depend on Figure 6 It can be seen that the blow-by gas in the descending section forms an air plug at the bottom, which makes the particle phase in the descending section form a throttling fluidization state, and the particle phase in the descending section is pushed upward by the throttling gas plug, which on the one hand aggravates the entrainment of the particle phase in the descending section; On the one hand, the time for the particles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com