Preparing method of high-weather-resistance reconsolidated bamboo

A technology of high weather resistance and recombined bamboo, which is applied in the direction of pretreatment of flat products, manufacturing tools and molding materials, etc., can solve the problems of poor dimensional stability, high water absorption thickness expansion rate, poor weather resistance, etc., and achieve guaranteed density and density, Effect of improving dimensional stability and ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1 Cold-pressing heat-curing method prepares highly weather-resistant recombined bamboo

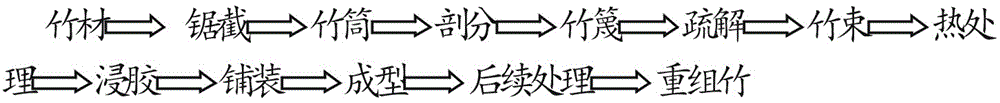

[0017] High weather resistance recombinant bamboo craft, such as figure 1 As shown, including sawing, splitting, defrosting, heat treatment, dipping, drying, paving and molding processes:

[0018] (1) Sawing

[0019] Saw fresh bamboo into 2000mm bamboo tubes,

[0020] (2) Split

[0021] Split the bamboo into 20-30mm bamboo strips, remove the bamboo green and bamboo yellow, and then divide it into bamboo strips with a thickness of 3mm;

[0022] (3) Release

[0023] Using a debonding machine, several cracks are formed in the longitudinal direction of the bamboo strips, and the bamboo strips are decomposed into bamboo bundles composed of 2mm bamboo fiber bundles; the moisture content of the decomposed bamboo bundles is detected by a moisture content detector, and the moisture content is selected to be greater than 30%. bamboo bundles;

[0024] (4) Heat treatment

[00...

Embodiment 2

[0034] Embodiment 2 hot pressing method prepares high weather resistance recombinant bamboo

[0035] High weather resistance recombinant bamboo craft, such as figure 1 As shown, including sawing, splitting, defrosting, heat treatment, dipping, drying, paving and molding processes:

[0036] (1) Sawing

[0037] Saw fresh bamboo into 2600mm bamboo tubes,

[0038] (2) Split

[0039] The bamboo is divided into 20-30mm bamboo strips, and after removing the green and yellow bamboo, it is divided into bamboo strips with a thickness of 2mm;

[0040] (3) Release

[0041] Using a debonding machine, several cracks are formed in the longitudinal direction of the bamboo strips, and the bamboo strips are decomposed into bamboo bundles composed of 3mm bamboo fiber bundles; the moisture content of the decomposed bamboo bundles is detected by a moisture content detector, and the moisture content is selected to be greater than 30%. bamboo bundles;

[0042] (4) Heat treatment

[0043] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com