High-speed hydraulic punching machine

A hydraulic press, high-speed technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of single function and low speed of hydraulic presses, and achieve the effect of improving safety performance, fast and efficient stamping production, and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

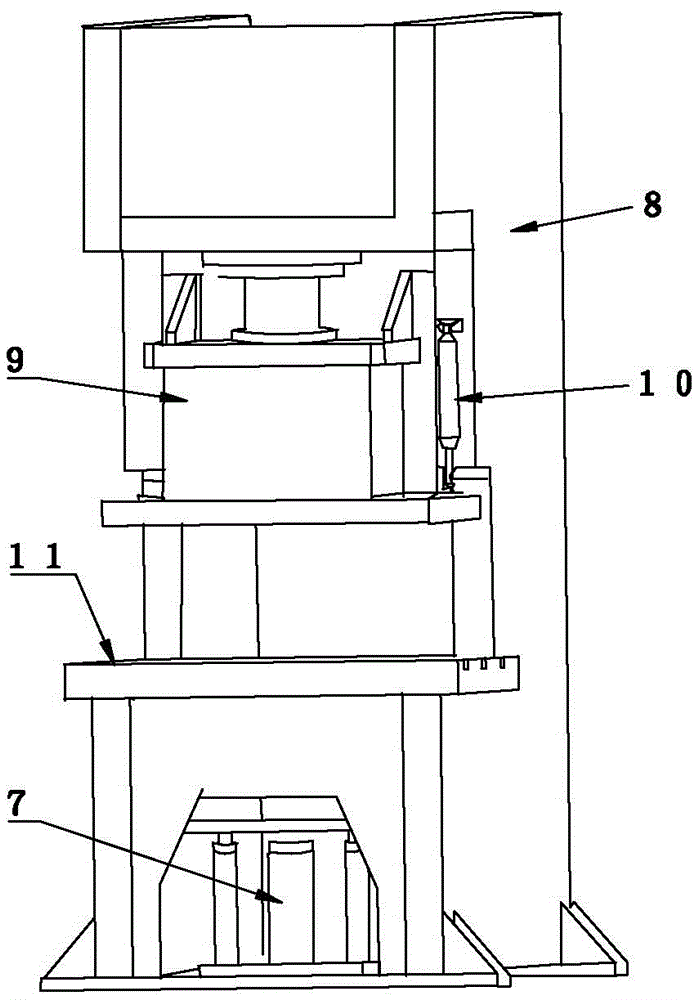

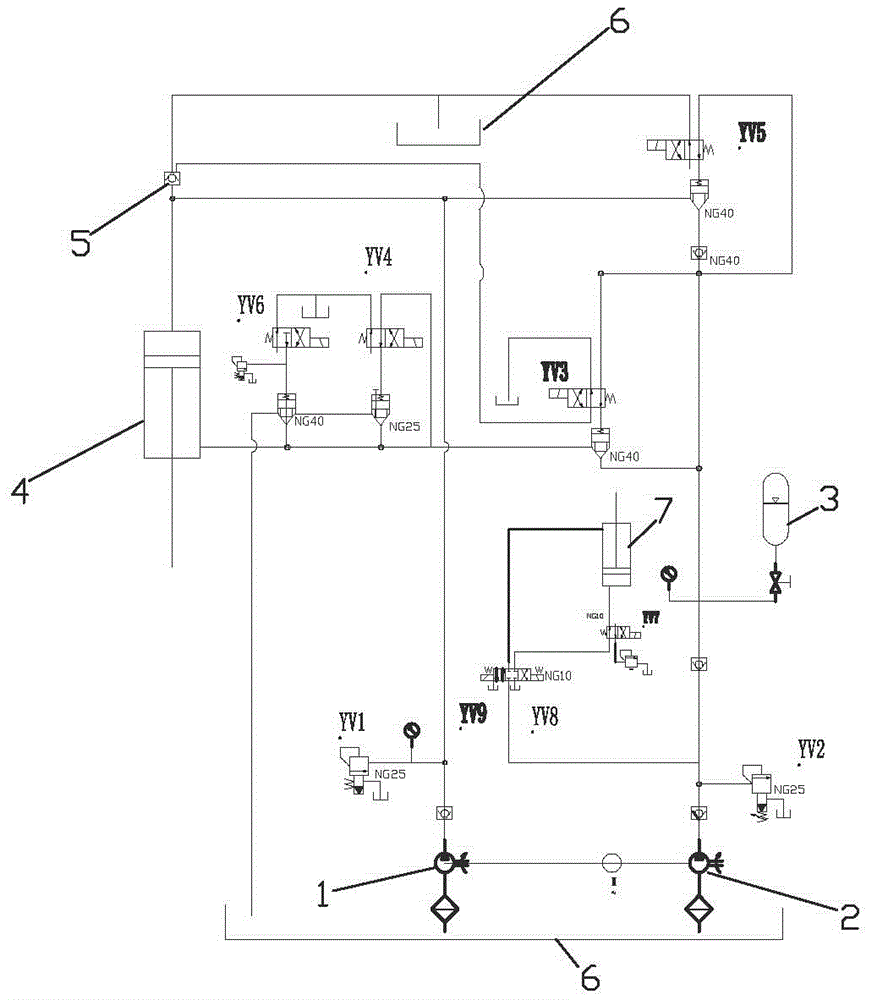

[0033] Such as figure 1 , 2 shown.

[0034] A high-speed hydraulic press, which includes a bed 8 and a slider 9, one end of an electronic ruler 10 is fixed on the bed 8, the other end is connected to the slider 9, the slider 8 is connected to the piston in the hydraulic cylinder 4, and the slider 8 Drive the piston down under the action of gravity and use gravity to directly absorb oil from the oil tank 6 to the working chamber. When the slider 9 goes down to the set position, the electronic ruler 10 drives the control system so that the double oil pump can quickly supply oil to the working chamber of the hydraulic cylinder at the same time to drive the piston. Drive the slider down quickly to realize high-speed stamping. When the slider goes down to the lower limit position, the electronic ruler 10 drives the control system again to stop one oil pump from supplying oil, so that the other oil pump and accumulator 3 can quickly supply oil to the oil return chamber of hydraulic...

Embodiment 2

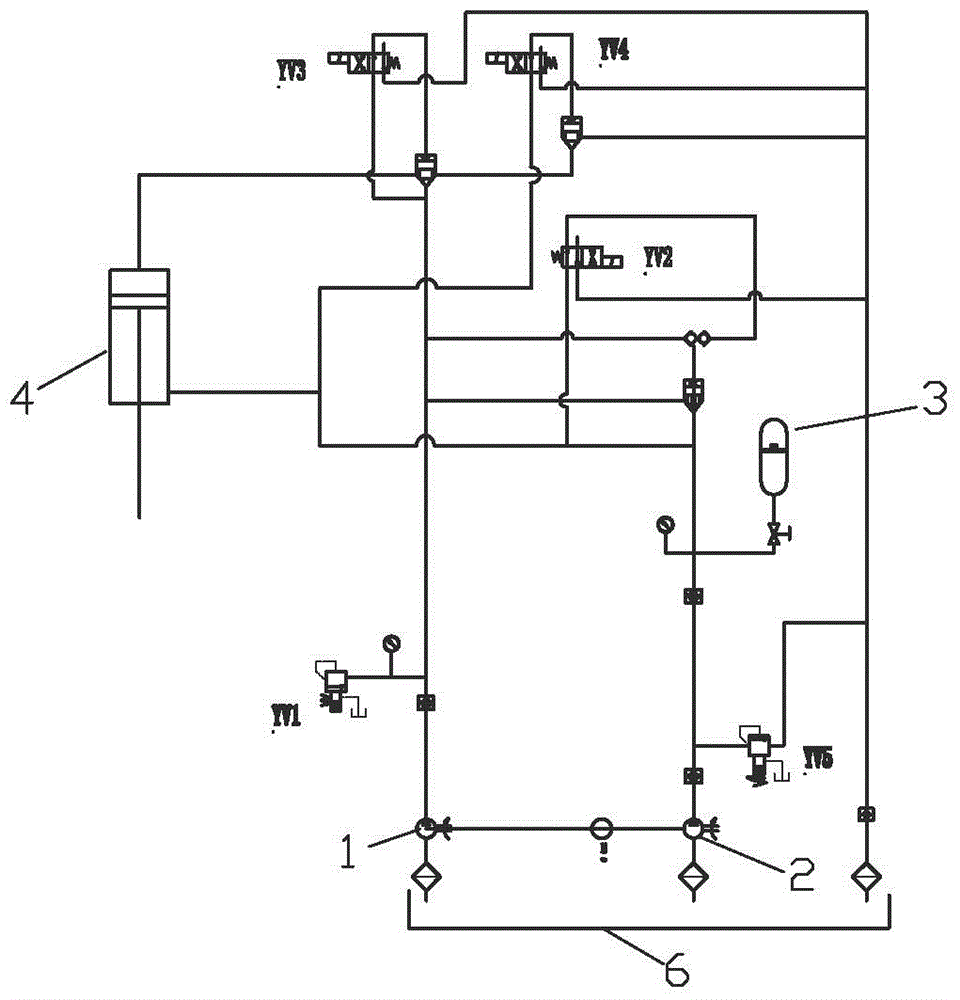

[0050] Such as figure 1 , 3 shown.

[0051] The difference between this embodiment and the first embodiment is that the hydraulic circuit is different. Since the pressure provided is relatively small (below 100 tons), its working principle is equivalent to that of the first embodiment, and the hydraulic circuit of the first embodiment can also be used. The schematic diagram of the hydraulic system of this embodiment is as follows image 3 shown.

[0052] The working process of this embodiment is:

[0053] 1. Standby.

[0054] All solenoid valves in the system are in a de-energized state. At this time, the hydraulic oil output by the oil pump is directly returned to the oil tank through the YV1 and YV2 electromagnetic overflow valves, that is, the hydraulic system is in a standby state.

[0055] 2. Fast down the slider.

[0056] When the slider is fast down, the YV1, YV2, YV3, YV5 solenoid valves are energized at the same time. Therefore, the hydraulic oil output by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com