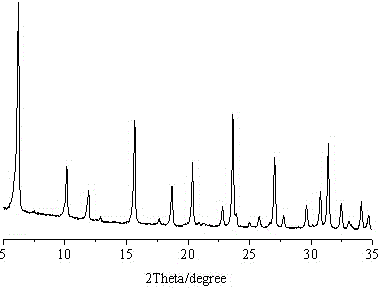

NaY type molecular sieves and preparation method therefor

A molecular sieve and amorphous silica-alumina technology, which is applied in the directions of fajhedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of poor catalytic effect and selectivity, and achieve the effect of improving diffusivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

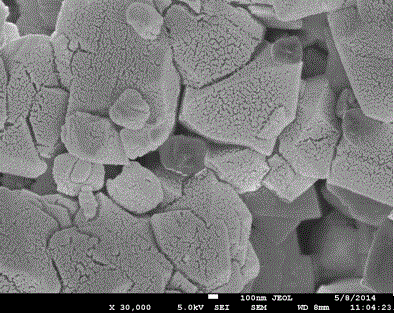

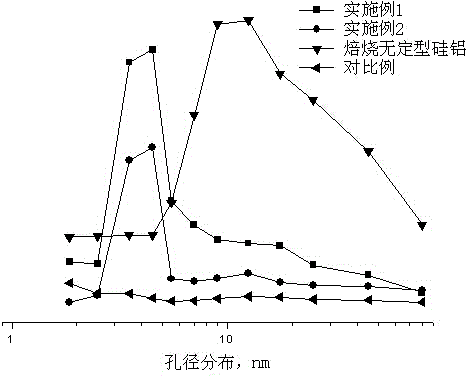

Embodiment 1

[0030] (1) According to the molar ratio n (Na 2 O): n (Al 2 o 3 ): n (SiO 2 ): n (H 2 O)=16:1:18:360, under stirring, add sodium aluminate, water, sodium hydroxide and water glass to the beaker in turn to form a mixed solution, and then age at 25°C for 2 days to obtain the directing agent .

[0031] (2) Under the condition of stirring, add the roasted amorphous silica aluminum, sodium hydroxide, water, water glass and the directing agent prepared in step (1) into the beaker to form a gel system. Constant temperature crystallization at 60°C for 8 hours, then constant temperature crystallization at 90°C for 60 hours, then cooling, washing, suction filtration, and drying to obtain NaY molecular sieves. The molar ratio of each material in the gel system (excluding the added roasted amorphous silica-alumina and directing agent) is n (NaOH): n (SiO 2 ): n (H 2(0)=15.5:12:470, the mass of the added roasted amorphous silica-alumina accounts for 6wt% of the total mass of ...

Embodiment 2

[0033] (1) According to the molar ratio n (Na 2 O): n (Al 2 o 3 ): n (SiO 2 ): n (H 2 O)=18:1:19:350, under stirring, add sodium aluminate, water, sodium hydroxide and water glass to the beaker in turn to form a mixed solution, and then age at 32°C for 1 day to prepare the directing agent .

[0034] (2) Under the condition of stirring, add the roasted amorphous silica aluminum, sodium hydroxide, water, water glass and the directing agent prepared in step (1) into the beaker to form a gel system. Constant temperature crystallization at 65°C for 10 hours, then constant temperature crystallization at 100°C for 48 hours, then cooling, washing, suction filtration, and drying to obtain NaY molecular sieves. The molar ratio of each material in the gel system (excluding the added roasted amorphous silica-alumina and directing agent) is n (NaOH): n (SiO 2 ): n (H 2 (0)=15.5:13:550, the mass of the added roasted amorphous silica-alumina accounts for 10wt% of the total mass...

Embodiment 3

[0036] (1) According to the molar ratio n (Na 2 O): n (Al 2 o 3 ): n (SiO 2 ): n (H 2 O)=16:1:18:340, in the state of stirring, sodium aluminate, water, sodium hydroxide and water glass were added to the beaker in turn to form a mixed solution, and then aged at 40°C for 1.5 days to obtain the directing agent .

[0037] (2) Under the condition of stirring, add the roasted amorphous silica aluminum, sodium hydroxide, water, water glass and the directing agent prepared in step (1) into the beaker to form a gel system. Constant temperature crystallization at 60°C for 12 hours, then constant temperature crystallization at 95°C for 48 hours, then cooling, washing, suction filtration, and drying to obtain NaY molecular sieves. The molar ratio of each material in the gel system (excluding the added roasted amorphous silica-alumina and directing agent) is n (NaOH): n (SiO 2 ): n (H 2 (0)=16:11:480, the mass of the added roasted amorphous silica-alumina accounts for 6wt% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com