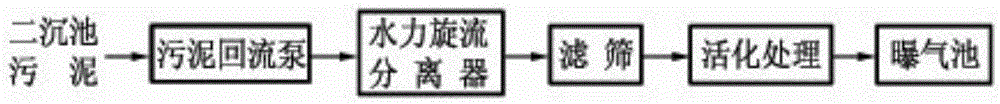

Returned sludge elutriation process of biological sewage treatment system

A technology for biological sewage treatment and sludge return, which is applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. The treatment effect of sewage in the aeration tank, etc., can improve the adsorption and oxidation performance, improve the removal rate, and improve the efficiency of sewage treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

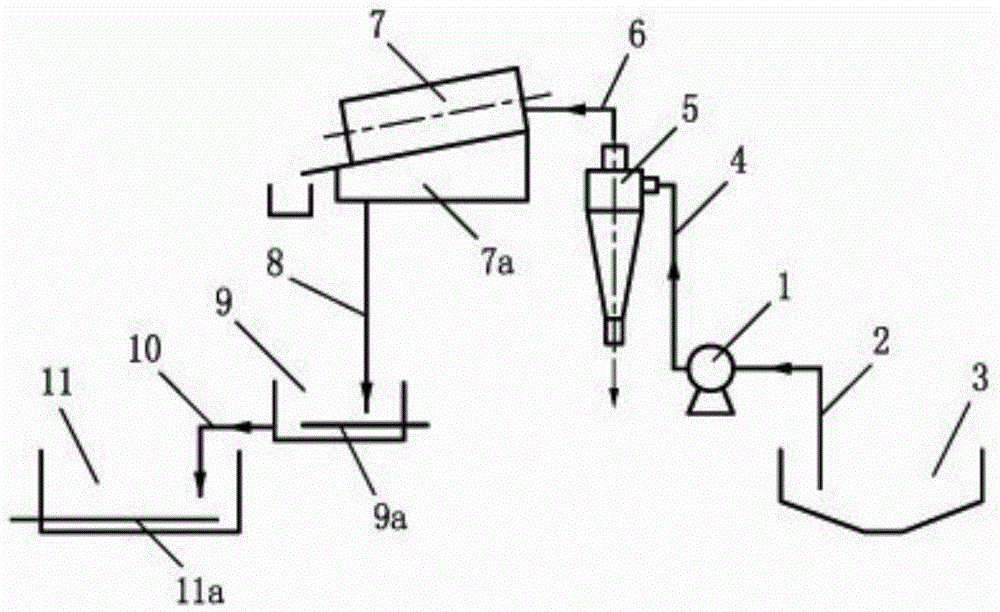

[0019] The sludge mixture in the secondary sedimentation tank 3 in the sewage biological treatment system is transported to the hydrocyclone 5 by the sludge return pump 1; the inlet of the sludge return pump 1 passes through the first sludge delivery pipe 2 and the lower part of the secondary sedimentation tank 3 The sludge layer is connected, and the outlet of the sludge return pump 1 is connected with the inlet of the hydrocyclone 5 through the second sludge delivery pipe 4 .

[0020] Under the power of the sludge return pump 1, the return sludge enters the hydrocyclone from the tangential feeding pipe on the upper part of the hydrocyclone, and generates a high-speed rotating flow field in the cylindrical cavity, and the hydraulic The cyclone separator 5 is to separate the fine particles and other impurities in the return sludge, so as to realize the separation of inorganic particles, and the separated inorganic particles and other impurities are separated by the hydrocyclone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com