Production technique of fudosteine

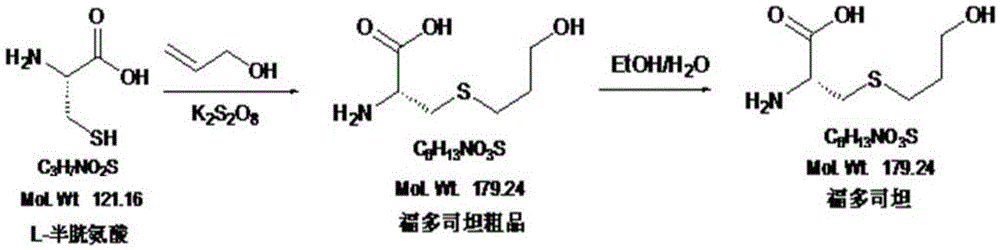

A production process, fudosteine technology, applied in the field of fudosteine production process, can solve the problems of low product purity and low yield, and achieve the effects of reducing occupational hazards, low cost, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

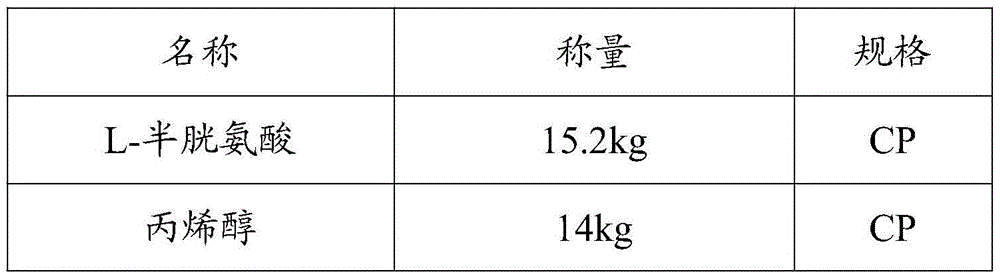

[0017] 1. Production raw materials:

[0018] raw material name

Production usage

Specification

purpose

L-cysteine

15.2kg

CP

starting material

Acryl alcohol

14kg

CP

Reactive ingredients

1.5kg

AR

catalyst

Absolute ethanol

114kg

CP

Reaction solvent

0.190kg

Medicinal

bleaching

[0019] 2. Production process

[0020] (1) synthesis of fudosteine crude product

[0021] Feeding

[0022]

[0023]

[0024] Theoretical output value: Fudosteine crude product 18.8Kg

[0025] Specific operation process:

[0026] In a 500L glass-lined reactor, dissolve 15.2kg of L-cysteine in 140.0kg of purified water, stir and dissolve, add 1.5kg of potassium persulfate and 14kg of propylene alcohol, after the addition is complete, stir and react at a temperature of 30±2°C for 5 After ±1h, evaporate the solvent to dryness under redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com