Impact-resistant polypropylene material with high melt strength and preparation method therefor

A polypropylene material, high melt strength technology, applied in the field of polypropylene materials, can solve problems such as insufficient rigidity, toughness or impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

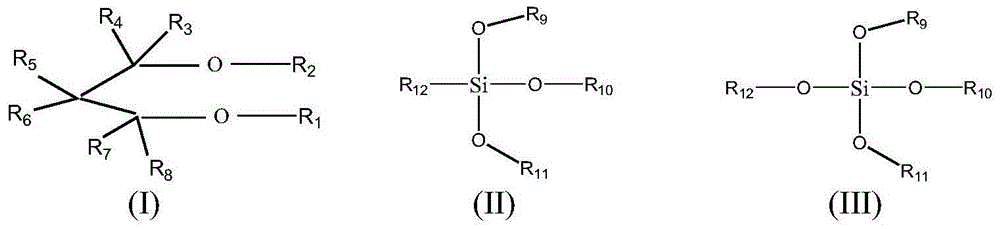

Method used

Image

Examples

Embodiment 1

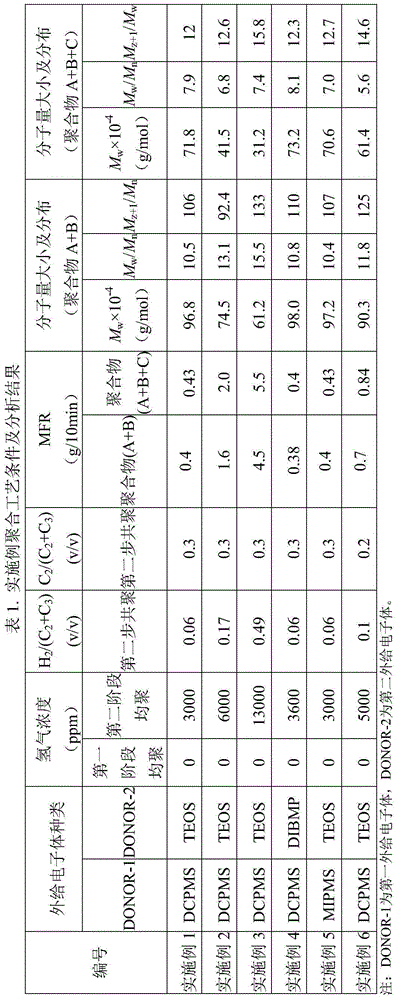

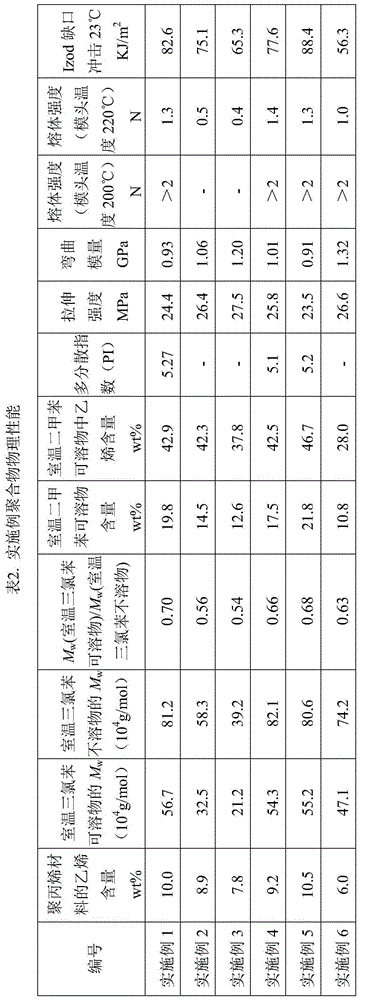

[0064] The propylene polymerization reaction is carried out on a polypropylene unit, and the main equipment of the unit includes a prepolymerization reactor, a first loop reactor, a second loop reactor and a third gas phase reactor. The polymerization method and steps are as follows.

[0065] (1) Prepolymerization reaction

[0066] The main catalyst (DQC-401 catalyst, provided by Sinopec Catalyst Company Beijing Aoda Branch), the cocatalyst (triethylaluminum), the first external electron donor (dicyclopentyl-dimethoxysilane, DCPMS) after 6 ℃, 20min after pre-contact, continuously into the continuous stirred tank prepolymerization reactor for prepolymerization reactor. The flow rate of triethylaluminum (TEA) entering the prepolymerization reactor is 6.33g / hr, the flow rate of dicyclopentyl-dimethoxysilane is 0.3g / hr, the flow rate of the main catalyst is 0.6g / hr, and the ratio of TEA / DCPMS is 50 (mol / mol). The pre-polymerization is carried out in the bulk environment of the ...

Embodiment 2

[0074] The catalyst used in embodiment 2, pre-complexation, polymerization process conditions and auxiliary agent formula and add-on are the same as embodiment 1. The difference with Example 1 is: the amount of hydrogen in the second reactor becomes 6000ppm in the second stage, and the H in the second step gas phase reactor 2 / (C 2 +C 3 ) adjusted to 0.17 (v / v). The obtained polymer analysis results and polymer physical properties are listed in Table 1 and Table 2.

Embodiment 3

[0076] The catalyst used in embodiment 3, pre-complexation, polymerization process conditions and auxiliary agent formula and addition are the same as embodiment 1. The difference with Example 1 is: the amount of hydrogen in the second reactor becomes 13000ppm in the second stage, and the H in the second step gas phase reactor 2 / (C 2 +C 3 ) adjusted to 0.49 (v / v). The obtained polymer analysis results and polymer physical properties are listed in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com