Foundation pit groundwater recharging system

A groundwater and foundation pit technology, applied in construction engineering, foundation pit engineering, and municipal fields, can solve problems such as affecting the effect of recharge and clogging of recharge wells, and achieve the effects of improving recharge effect, reducing clogging, and optimizing water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

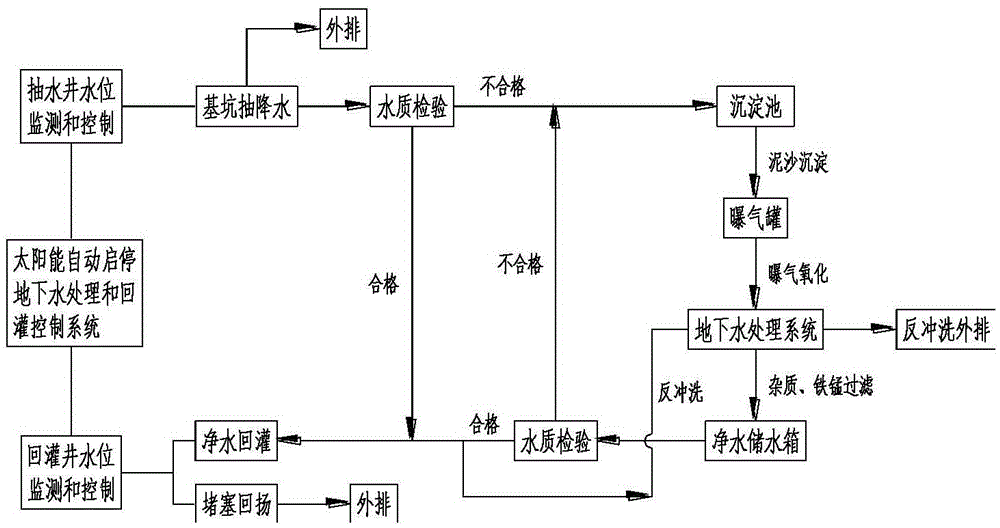

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

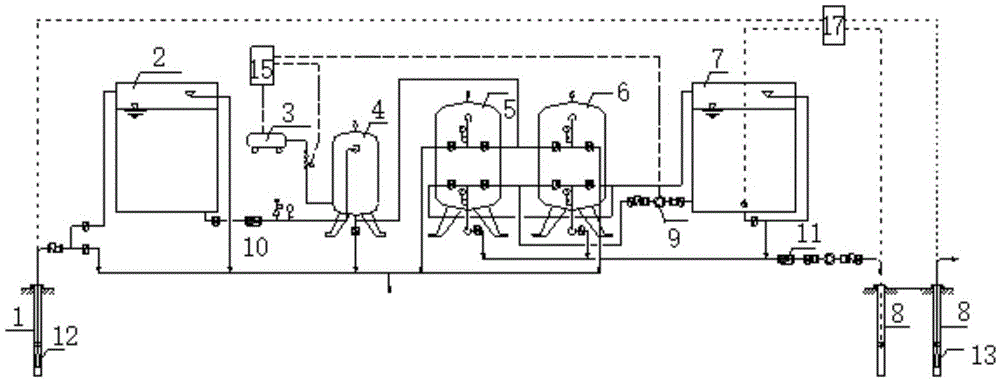

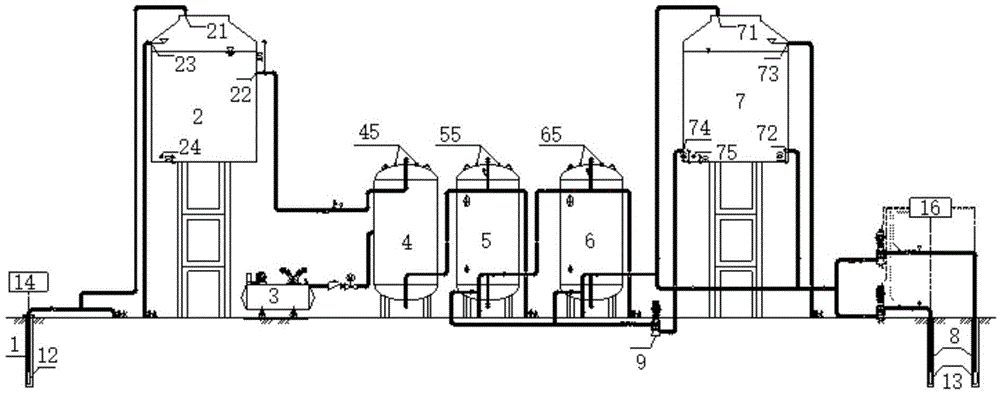

Embodiment 1

[0048] This embodiment relates to a groundwater recharge system for foundation pits, and its structural diagram is as follows image 3 As shown, it includes a pumping well 1, a primary water storage tank 2, an aeration unit, a primary filter 5, a secondary filter 6, a secondary water storage tank 7 and a recharge well 8 connected in sequence, and also includes a backwashing unit, The control processing unit and the water level monitoring unit; the backwashing unit is connected with the primary filter 5 and the secondary filter 6 respectively; the water level monitoring unit is connected with the pumping well 1, the secondary water storage tank 7 and the recharge well 8 respectively The control processing unit includes a pumping control subunit connected to the pumping well 1, a water treatment control subunit connected to the recharge water quality treatment system, and a recharge and flow control subunit connected to the recharge well 8. As a preferred implementation of this ...

Embodiment 2

[0089] This embodiment relates to a foundation pit groundwater recharge system, and its system composition and process operation are the same as those in Embodiment 1. The difference lies in that the choice of filter fillers in the primary and secondary filters in this embodiment is different from that in Embodiment 1. In this example, on the basis of Example 1, in combination with the groundwater quality of the foundation pit, the filtering effect and the filtering cost, the following selection schemes for filter packings are determined:

[0090] Option One:

[0091] Primary filter: The quartz sand filter material layer (thickness = 1.8m) is laid with graded quartz sand filter material (d = 0.5-1.2mm, d = 1-2mm, volume ratio 1:1.5).

[0092] Secondary filter: with embodiment 1.

[0093] Option II:

[0094] Primary filter: with embodiment 1.

[0095] Secondary filter: such as Figure 8 As shown, on the filter screen 611, the SS filter material filter layer 612 of 1.2m, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com