Wall base cloth and manufacturing method thereof

A technology of wall base cloth and base cloth, which is applied in the direction of chemical instruments and methods, lamination, coating, etc., which can solve the problems of affecting the use function, plastic materials becoming hard and brittle, easy to migrate out, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

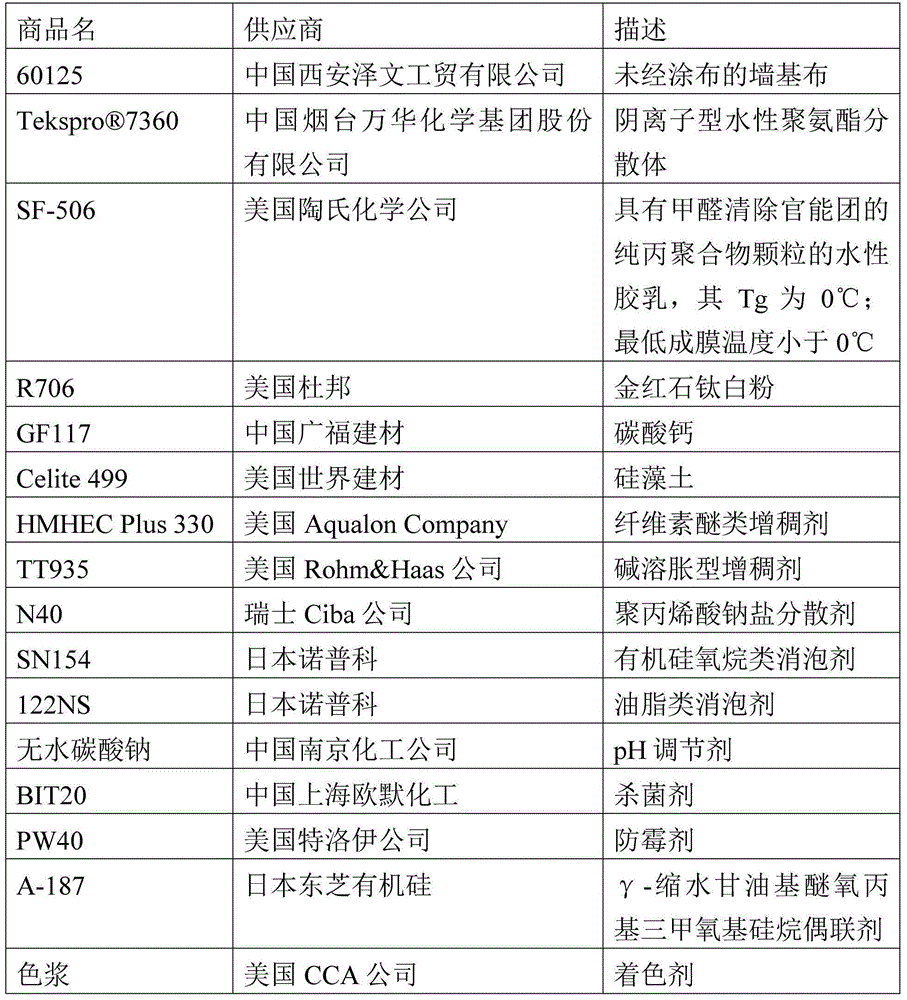

[0087] The preparation of the water-based coating composition of the present invention can be realized by any suitable mixing method known to those of ordinary skill in the art. For example, a waterborne coating composition can be prepared by adding the waterborne latex, filler and additives to a container, and then stirring the resulting mixture until homogeneous. Alternatively, the waterborne coating composition can be prepared by mixing some of the additional additives with the filler, and then adding the waterborne latex and the remainder of the additional additives to form a homogeneous mixture. Additional water can be added during preparation of the aqueous coating composition, if desired. Additional water should be added to the total weight of the aqueous latex.

[0088] The above-mentioned water-dispersible polyurethane-based aqueous coating composition of the present invention can be applied by conventional methods known to those skilled in the art, such as by spray ...

Embodiment 1-2

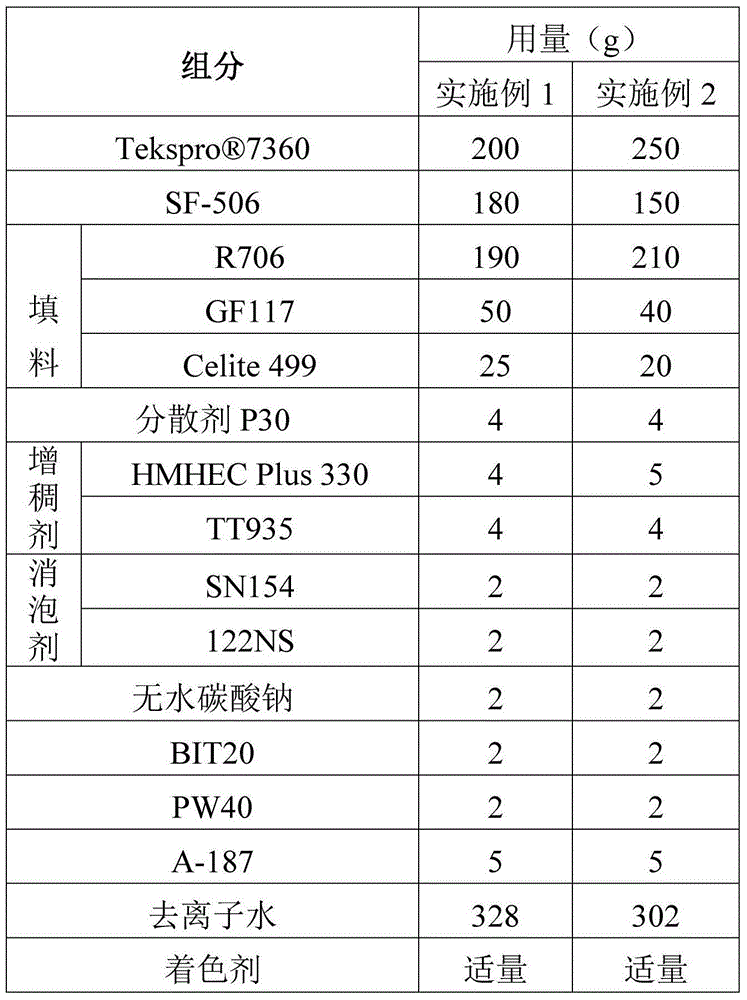

[0116] Embodiment 1-2: Preparation of water-dispersible polyurethane-based aqueous coating composition

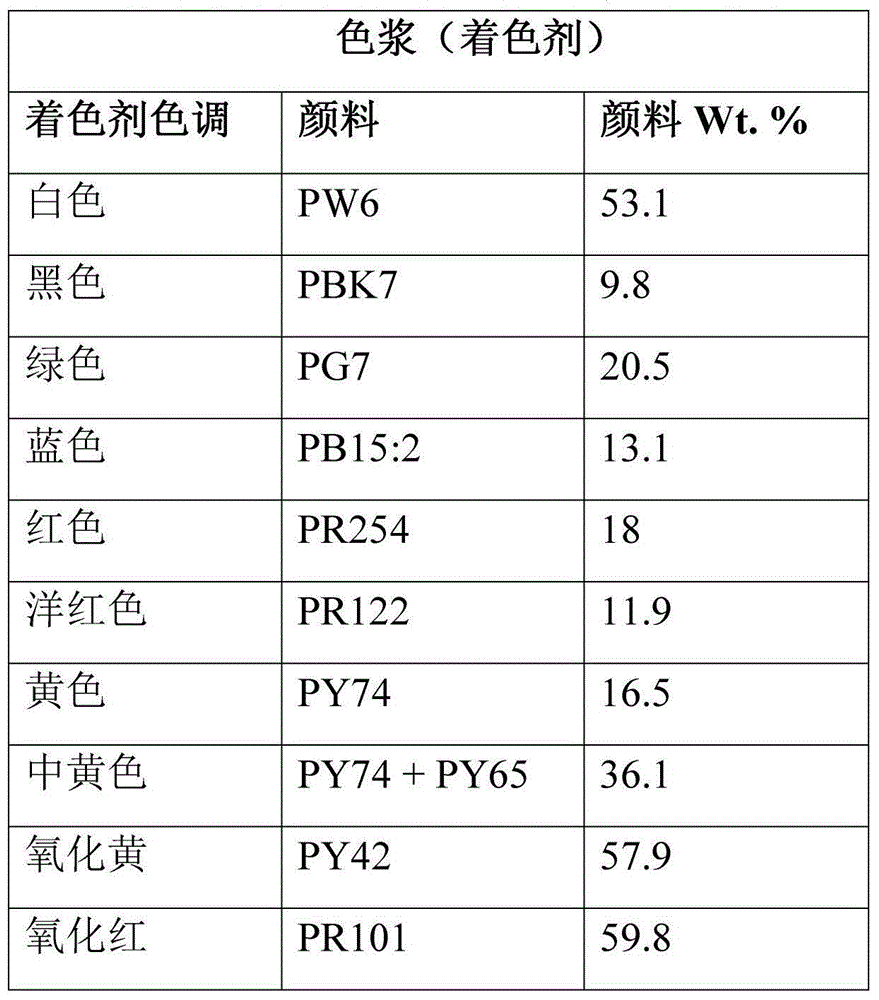

[0117] Under low-speed stirring at 350-450rpm, add 200g of deionized water, thickener HMHECPlus330, dispersant N40, defoamer SN154, pH regulator anhydrous sodium carbonate to the stirrer, and stir for 5-10 minutes until uniform . Then add filler rutile titanium dioxide, heavy calcium carbonate and diatomaceous earth to the mixture, and stir at 800-1250rpm at high speed for 20-30 minutes to form a uniform slurry. Finally, add defoamer 122NS, 7360 water-based polyurethane dispersion, SF-506 acrylic emulsion, silane coupling agent, BIT20 fungicide, PW40 anti-fungal agent, thickener TT935, required coloring agent and the remaining part of deionized water until uniform to form a water-based paint combination. The usage amount of each component in the water-based coating composition of Examples 1-2 and the properties of the water-based coating composition and the coating fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com