Dust remover rear flue gas system provided with flue gas heat exchanger

A flue gas heat exchanger and heat exchanger technology, applied in the direction of waste gas exhaust device, climate sustainability, reduction of greenhouse gases, etc., can solve the problems of large land occupation, increased flue resistance, flue material consumption, etc., to achieve Reduce pressure loss, improve operating economy, and smooth flue connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

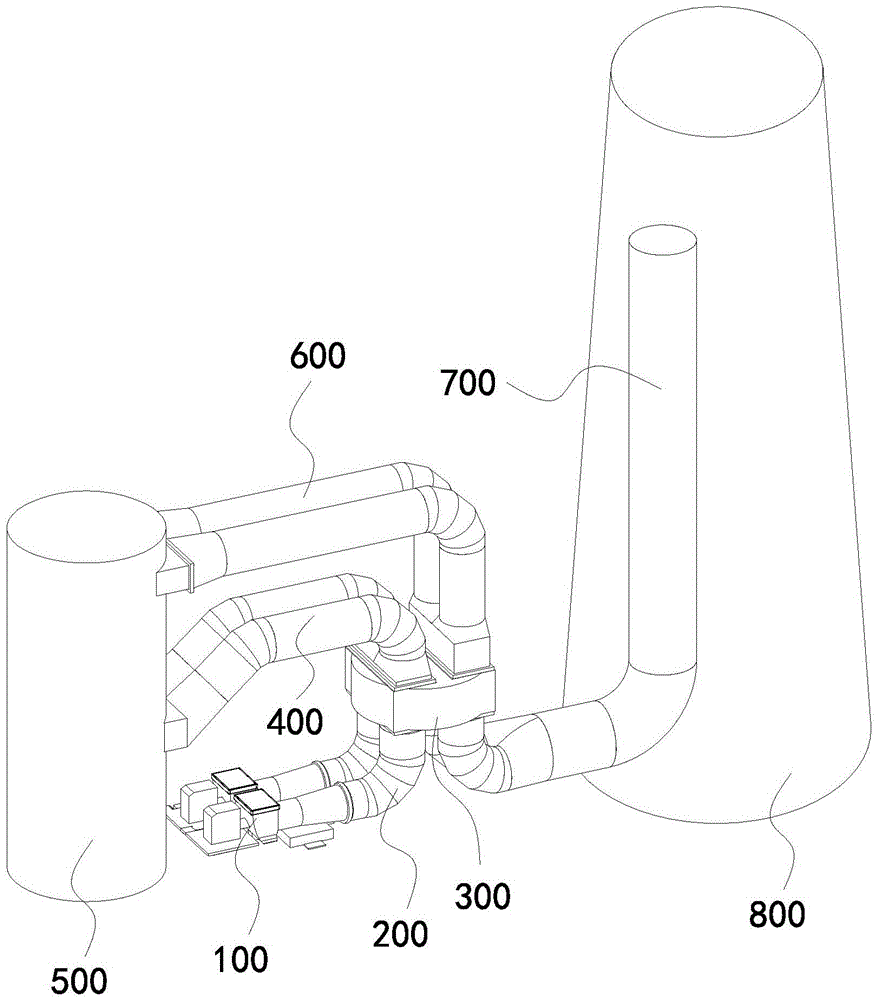

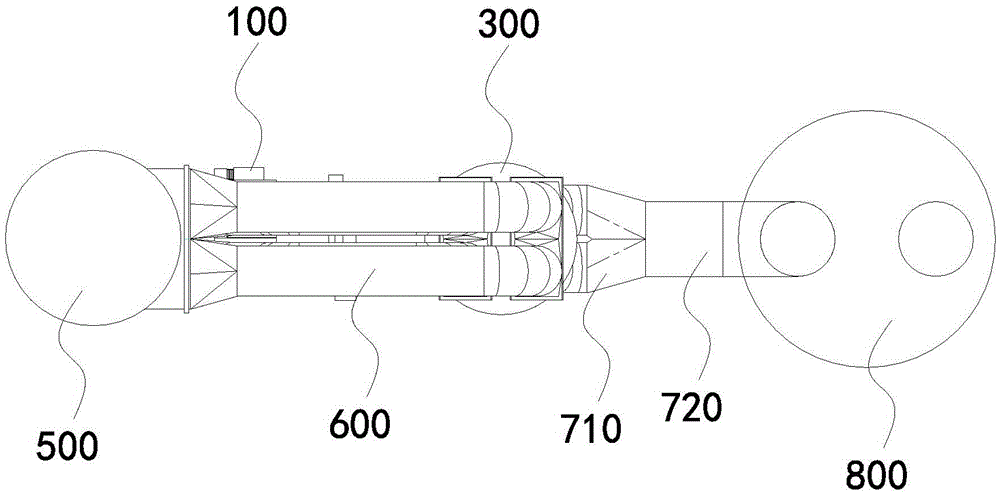

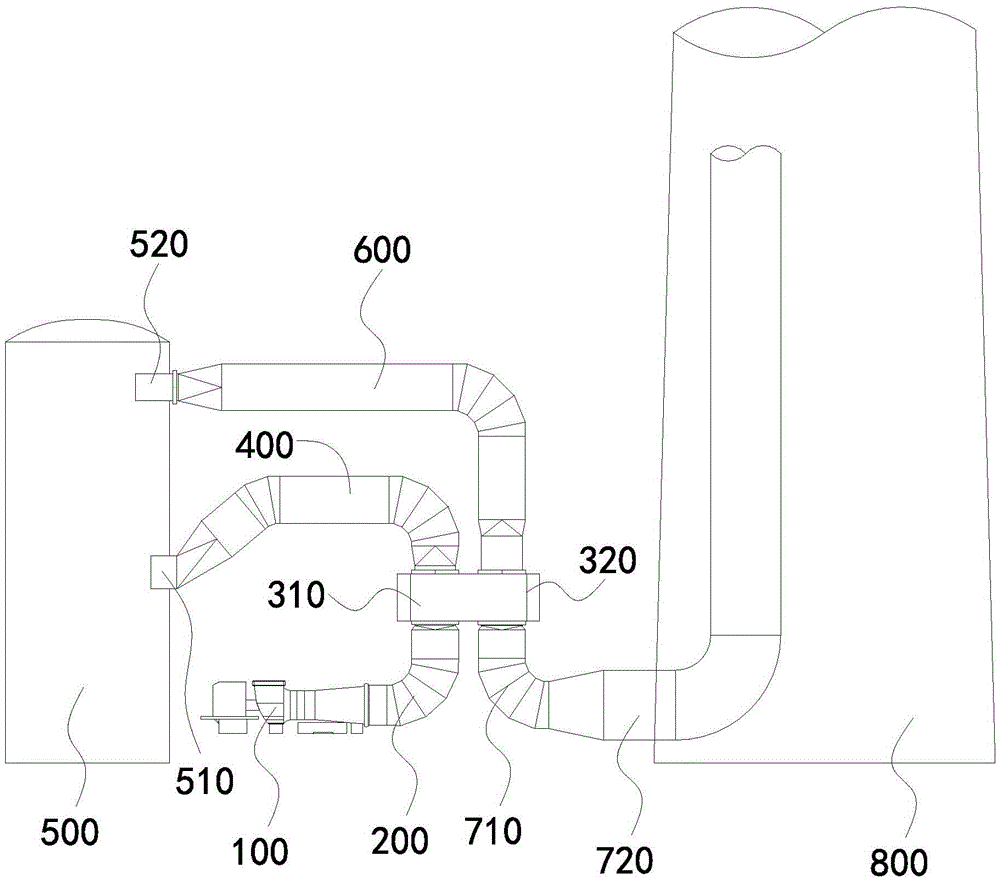

[0031] Such as figure 1 As shown, a flue gas system after a dust collector equipped with a flue gas heat exchanger includes a double-row induced draft fan 100 communicated with the outlet of the dust collector, a flue gas heat exchanger 300 communicated with the double-row induced draft fan 100, and The desulfurization absorption tower 500 communicated with the flue gas heat exchanger 300, and the chimney 800 communicated with the flue gas heat exchanger 300, and the double row induced draft fan 100, flue gas heat exchanger 300, desulfurization absorption tower 500 and the chimney 800 are all arranged on the same straight line. The desulfurization absorption tower 500 and the chimney 800 are vertically arranged side by side, and the double-row induced draft fan 100 and the flue gas heat exchanger 300 are arranged between the chimney 800 and the desulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com