Six-dimensional rapid high-precision alignment and measurement system based on zone plate

A measurement system and strip technology, applied in the field of precision instruments, can solve problems such as unfavorable operation and large judgment deviation, and achieve the effect of avoiding multi-dimensional independent measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

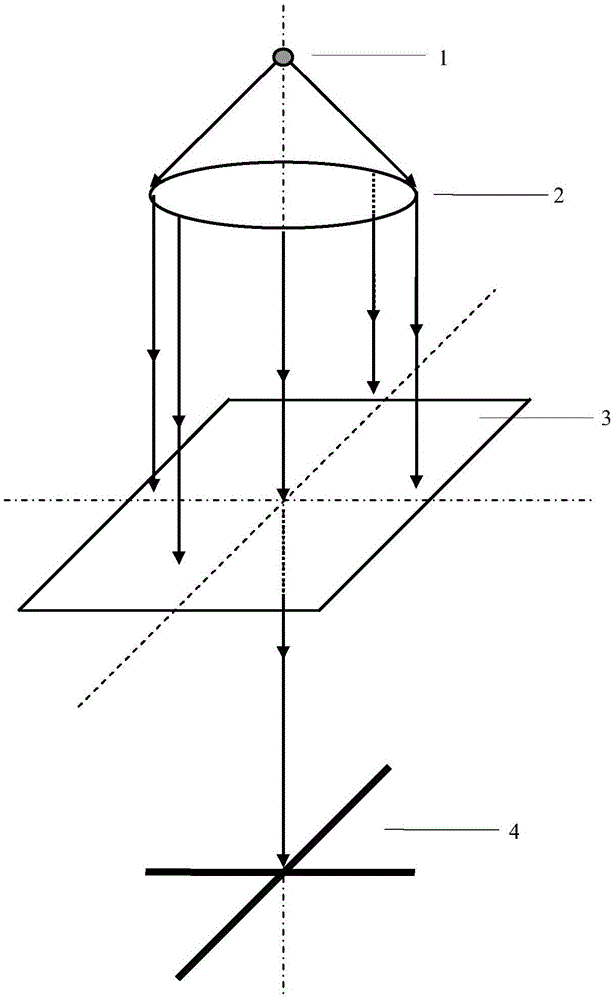

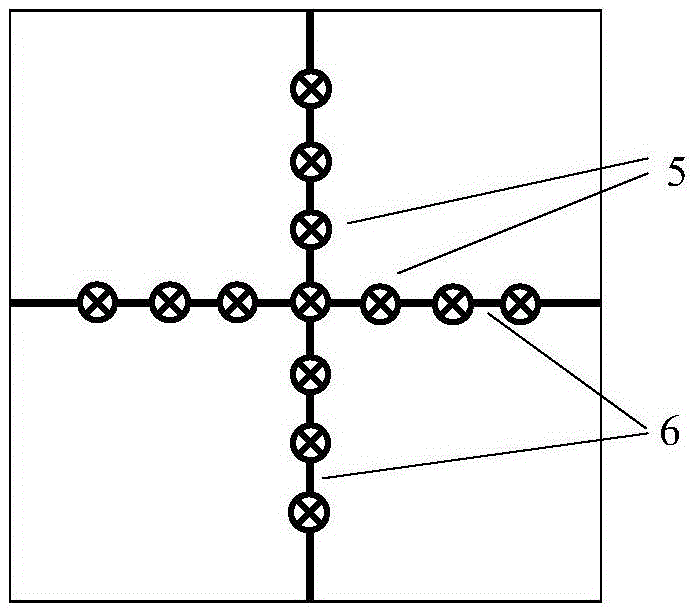

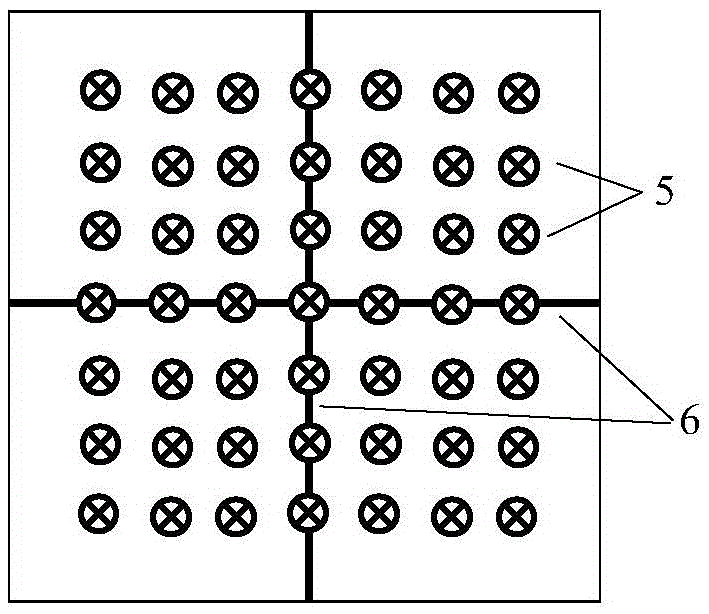

[0022] Such as figure 1 As shown, the present invention includes a two-dimensional zone plate 3, a collimated laser light source (realized by a light source 1 and a collimator lens 2, the laser wavelength corresponds to the zone plate design, and the laser light exit port and optical filter and collimation The lens is connected to obtain collimated light, and the collimated light illuminates the two-dimensional zone plate vertically), the light intensity adjustment device, and the probe array 5 composed of at least 4 photoelectric sensing probes (which can be four-quadrant diodes, photodiodes, CCD cameras, COMS camera, which can be sensitive to changes in the intensity of light), a special target panel, a control circuit, a support bracket, a photoelectric sensor probe fixed on the target panel, and a two-dimensional wave zone plate located between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com