Slide glass cover plate for slide glass sample treatment

A technology for specimen processing and slides, which is used in laboratory containers, support of flat carriers, preparation of samples for testing, etc. and other problems, to achieve the effect of ensuring reliability and repeatability, saving space, and sufficient heating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

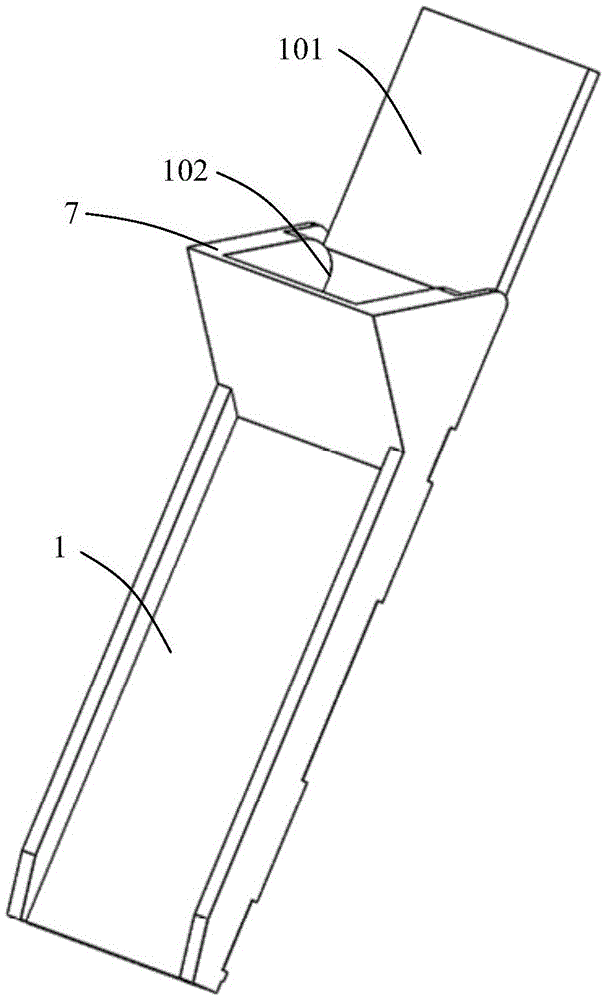

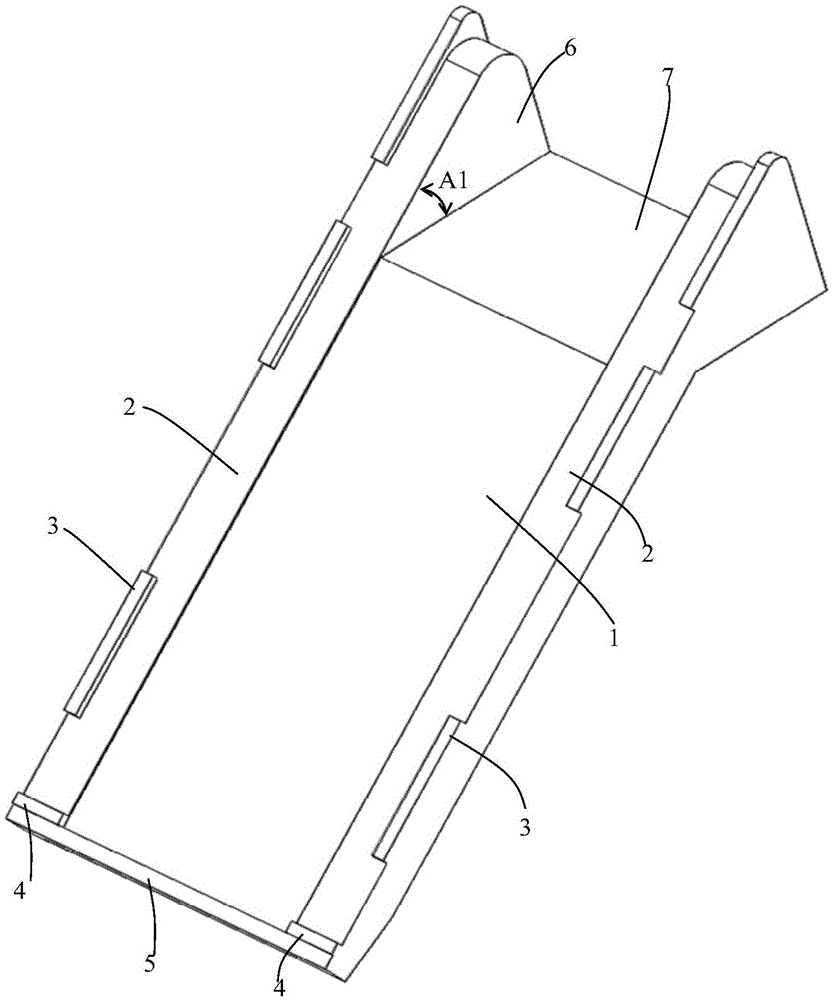

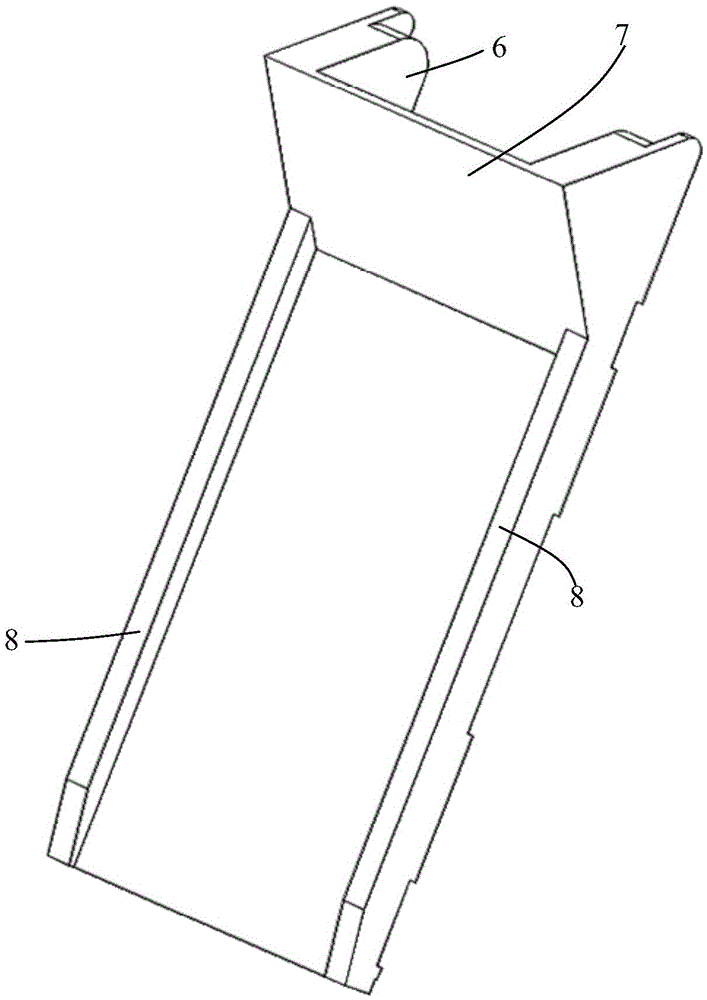

[0049] Example of implementation: the slide cover plate has the following dimensions: the length of the depth positioning surface 2 is 54mm, the distance between the inner sides of the two width positioning blocks 3 is 20mm, D1=0.2mm, D2=0.5mm, the length of the capillary plane is 40mm, The width is 20mm, and the angle between the groove opening surface and the depth positioning surface is 60 degrees. The length of the slide is 75mm, and the width is 25mm. The thickness of the sliced specimen is about 0.004mm. Experiments have shown that a capillary gap is formed between the capillary plane of the slide and the cover plate, which can form a capillary siphon effect, and the reagent fills the gap when adding a sample.

[0050] In the immunohistochemical staining, the slide assembly of the present invention is directly immersed in the boiling heat repair solution and partially inserted into the boiling heat repair solution at the bottom and heated for 40 minutes. The gaps are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com