Preparation method of iron composite oxide functional powder material

A technology of composite oxides and functional powders, applied in the directions of nickel oxide/nickel hydroxide, iron oxide/iron hydroxide, etc., can solve the problem that nanometerization is not suitable, does not fundamentally solve the inhomogeneity of precursor composition, composite Oxide grain size cannot be accurately controlled, etc., to achieve the effect of wide variety, uniform and stable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

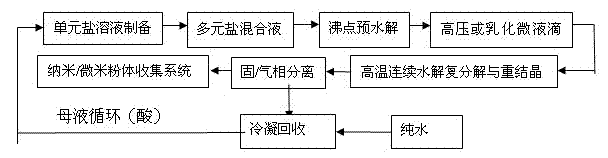

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing an iron composite oxide functional powder material, comprising the following steps:

[0041] A. For the preparation of the unit salt solution, according to the requirements of the designed functional iron composite oxide components, the water-soluble process of the salt of the relevant alloy elements or the preparation of the acid-soluble metal materials of the relevant alloy elements are respectively carried out.

[0042] With Zn 0.44 Ni 0.56 Fe 2 o 4 ferrite as an example, that is, Sb x Ba y Sr z Cr a Cu b mn c Zn d Ni e co f Mg g Fe 2 o 4 Type, where x=0, y=0, z=0, a=0, b=0, c=0, d=0.44, e=0.56, f=0, g=0; Zn / Ni / Fe three The alloying elements are in a molar ratio of 0.44:0.56:2 and the weighing unit salts zinc chloride, nickel chloride, and ferrous chloride (ferric chloride) are dissolved in water respectively; or metal zinc, metal nickel, and metal iron are dissolved in hydrochloric acid to prepare A unit salt solution with a pH...

Embodiment 2

[0054] A method for preparing an iron composite oxide functional powder material, comprising the following steps:

[0055] A. Preparation of the unit salt solution According to the requirements of the designed functional iron composite oxide components, the water-soluble process of the salt of the relevant alloy elements or the preparation of the acid-soluble metal materials of the relevant alloy elements are respectively carried out.

[0056] Take Cu 0.02 Zn 0.42 Ni 0.56 Fe 2 o 4 ferrite as an example, that is, Sb x Ba y Sr z Cr a Cu b mn c Zn d Ni e co f Mg g Fe 2 o 4 Type, where x=0, y=0, z=0, a=0, b=0.02, c=0, d=0.42, e=0.56, f=0, g=0; Cu / Zn / Ni / Fe The four alloying elements are dissolved in water at a molar ratio of 0.02:0.44:0.56:2. The weighing unit salts copper chloride, zinc chloride, nickel chloride, and ferrous chloride (ferric chloride) are respectively dissolved in water; or metal copper, Metal zinc, metal nickel, and metal iron are used to prepare...

Embodiment 3

[0066] A method for preparing an iron composite oxide functional powder material, comprising the following steps:

[0067] A. Preparation of the unit salt solution According to the requirements of the designed functional iron composite oxide components, the water-soluble process of the salt of the relevant alloy elements or the preparation of the acid-soluble metal materials of the relevant alloy elements are respectively carried out.

[0068] With Zn 0.44 mn 0.56 Fe 2 o 4 ferrite as an example, that is, Sb x Ba y Sr z Cr a Cu b mn c Zn d Ni e co f Mg g Fe 2 o 4 Type, where x=0, y=0, z=0, a=0, b=0, c=0.56, d=0.44, e=0, f=0, g=0; Zn / Mn / Fe three The alloying elements are dissolved in water respectively in the weighing unit salt zinc chloride, manganese chloride, and ferric chloride (or ferric chloride) at a molar ratio of 0.44:0.56:2; or the metal zinc, metal nickel, and metal iron are dissolved in hydrochloric acid to prepare The unit salt solution with a pH val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com