Method and system for desulfurization and dezincification of high-sulfur coal

A high-sulfur coal and denitrification technology, applied in separation methods, chemical instruments and methods, hydrogen sulfide, etc., can solve the problems of low field strength, clogging of sorting tanks, low gradients, etc., and achieve the effect of large economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

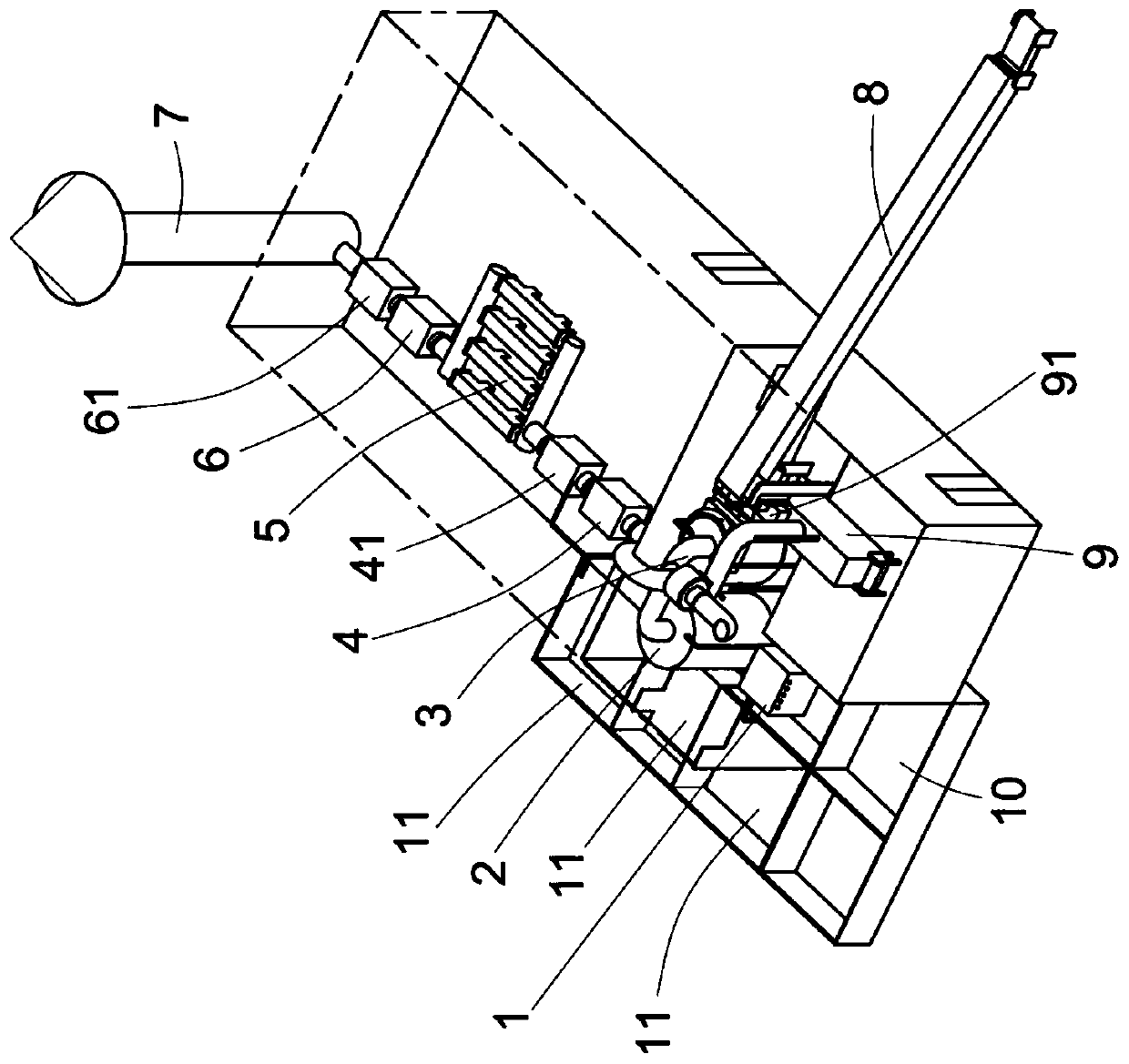

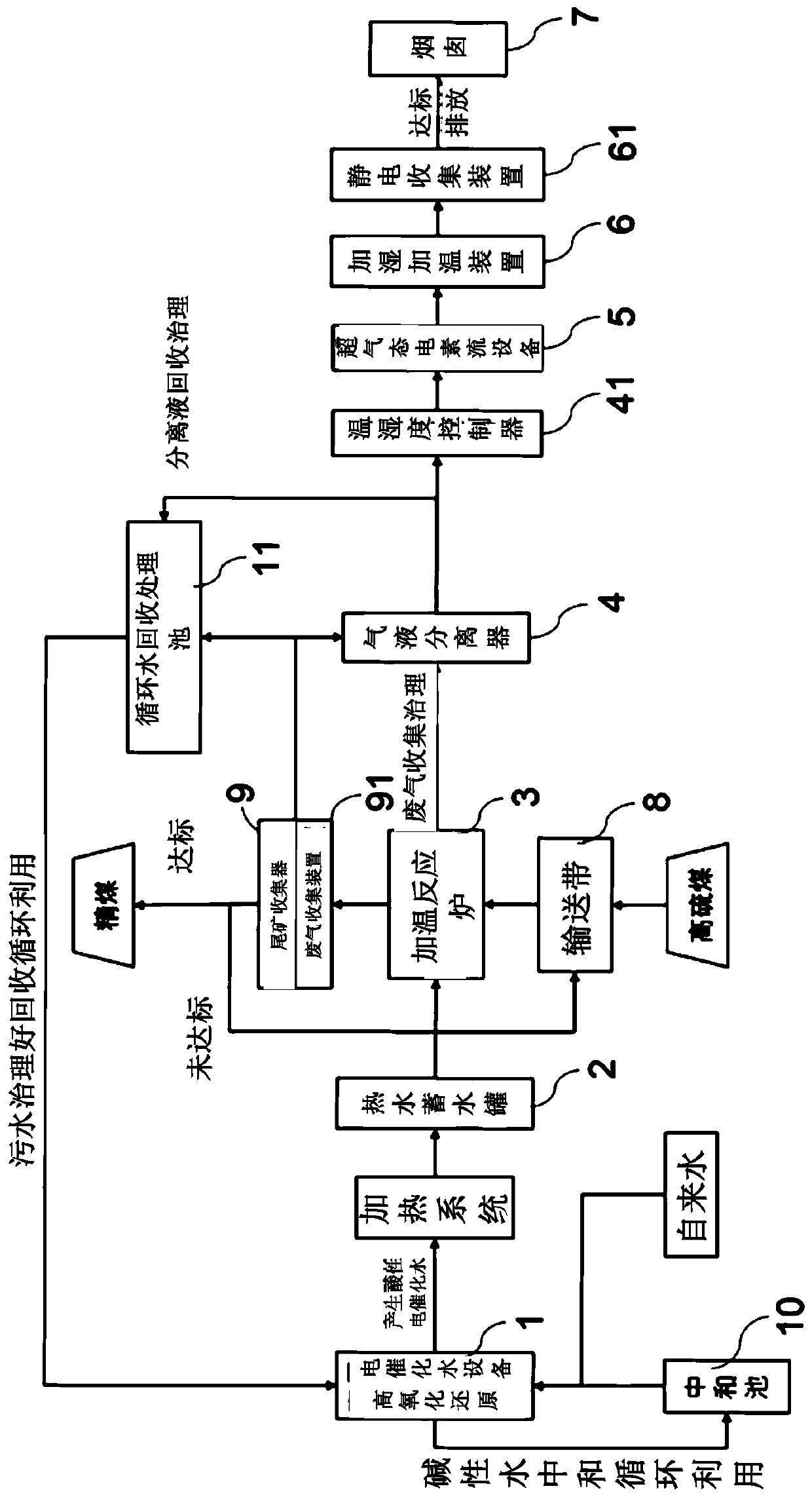

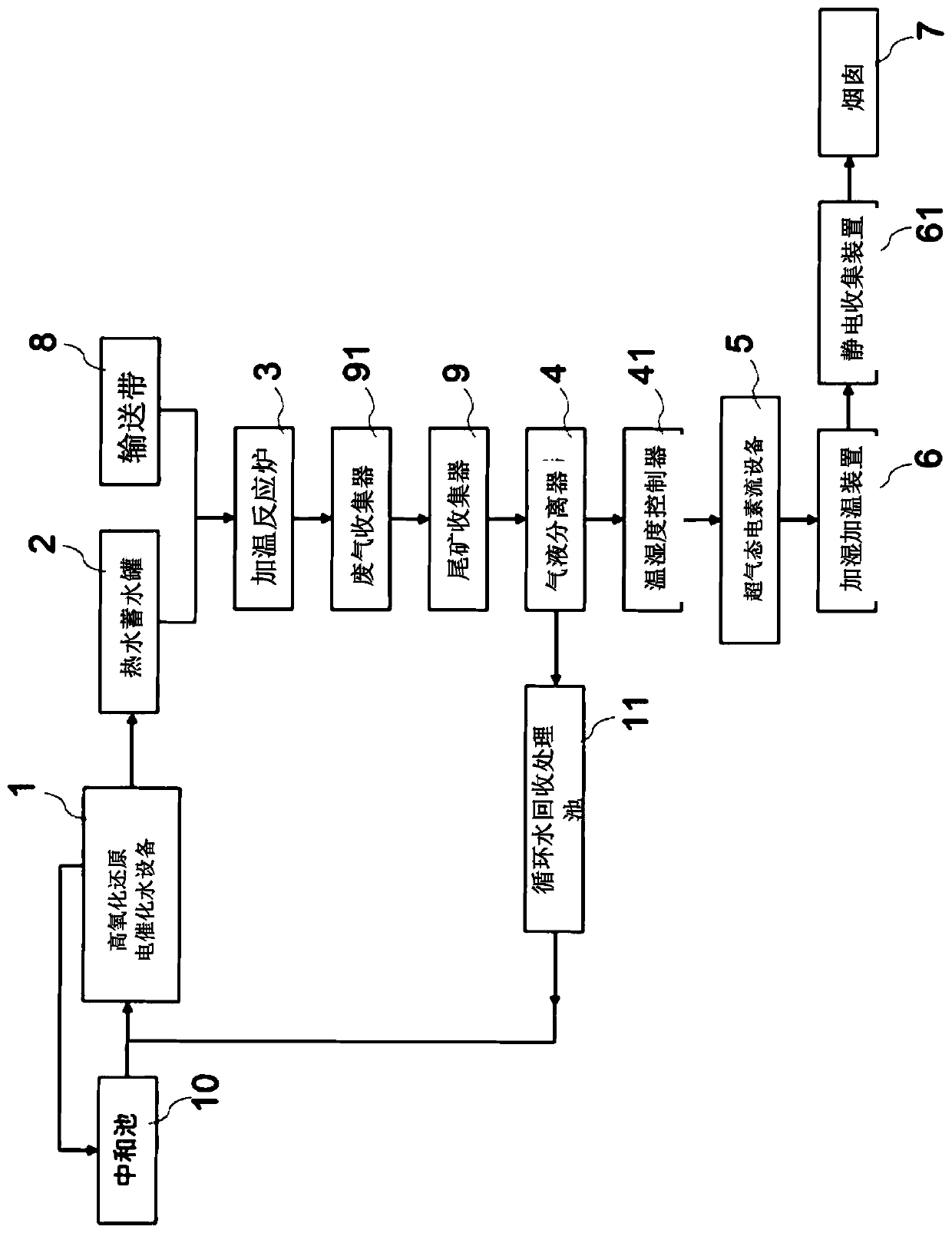

[0070] Attached below Figure 1-3 Specific embodiment 1 is described further:

[0071] The system for desulfurization and denitrification of high-sulfur coal in Example 1 includes high redox electrocatalytic water equipment (1), hot water storage tank (2), heating reaction furnace (3), gas-liquid separator (4), Temperature and humidity controller (41), supergaseous electric element flow equipment (5), humidification and heating device (6), electrostatic collection device (61), chimney (7), conveyor belt (8), tailings collector (9 ), exhaust gas collection device (91), neutralization tank (10) and circulating water recovery treatment tank (11); among them, high redox electrocatalytic water equipment (1) is equipped with acidic electrocatalytic water outlet and alkaline electrocatalytic water outlet Outlet; acidic electrocatalytic water outlet of high redox electrocatalytic water equipment (1), hot water storage tank (2), heating reaction furnace (3), waste gas collection devic...

Embodiment 2

[0076] In Example 2, the method for desulfurization and denitrification in high-sulfur coal is to pass tap water into high redox electrocatalytic water equipment, and the pH value of tap water will be reduced to below 6 through the regulation of the equipment; Soak high-sulfur coal in electrocatalytic water, stir evenly, heat to 90-100°C and react for 0.5-1 hour; then during the heating process, a large amount of H in acidic electrocatalytic water + It reacts with sulfur and nitrogen in coal to produce hydrogen sulfide gas and ammonia gas, which can effectively remove sulfur and nitrogen in coal, thereby improving the quality of coal mines and meeting the requirements. The hydrogen sulfide gas generated above will be collected through the pipeline and enter the super gaseous electric flow equipment for further decomposition and treatment; due to the desulfurization and denitrification of high-sulfur coal, the total carbon content will increase, and the quality will also be impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com