Thermoelectric battery with series-wound electric leg structure

A technology of thermoelectric battery and electric leg, applied in the field of thermoelectric battery, can solve problems such as difficulty in obtaining a large temperature gradient, and achieve the effect of being beneficial to popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

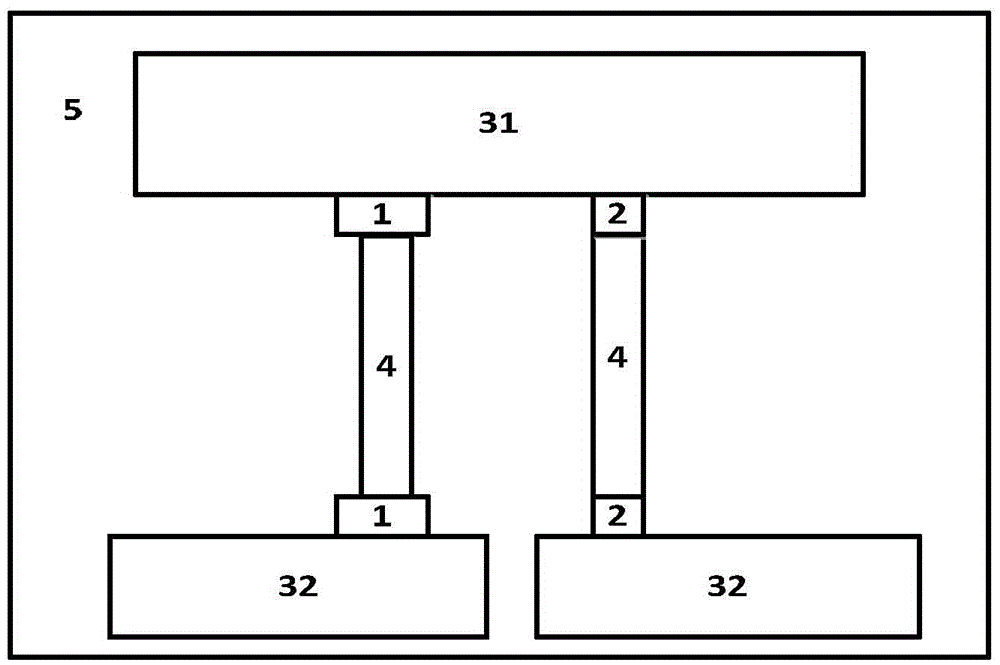

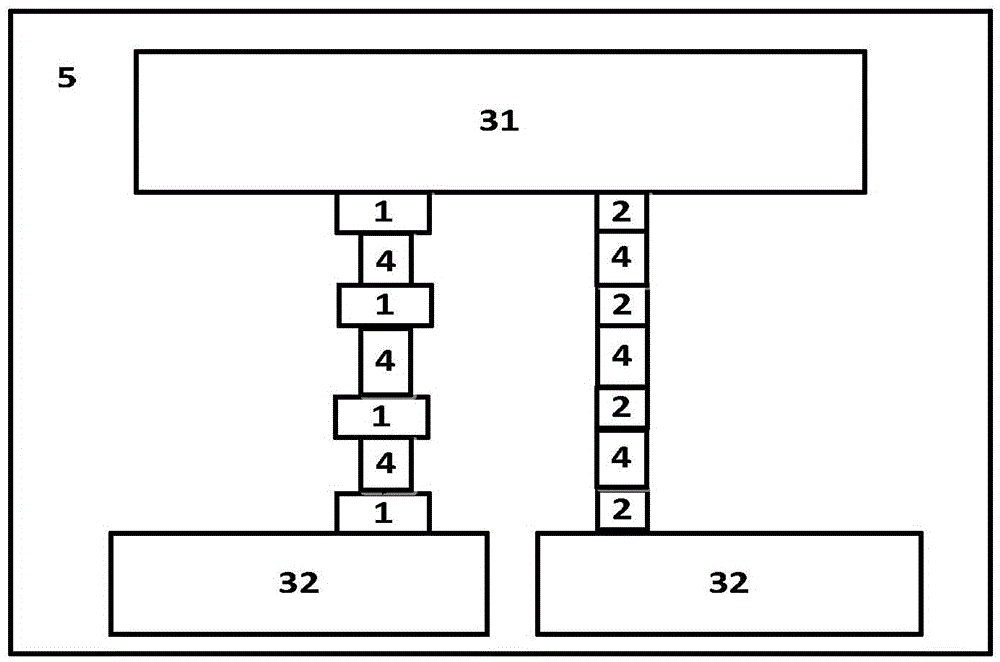

Image

Examples

Embodiment 1

[0017] 1. Choose a quartz plate as the substrate;

[0018] 2. Using thermal evaporation method to prepare two bismuth tellurium selenium thermoelectric films with a width of 5 mm and a length of 1 cm on the substrate, with an intermediate distance of 1 cm;

[0019] 3. Use the same method to prepare two bismuth, antimony, tellurium thermoelectric films with a length of 5 mm and a length of 1 cm, with an intermediate distance of 1 cm;

[0020] 4. Prepare the copper film connected to the bismuth-tellurium-selenium film and the copper film connected to the bismuth-antimony-tellurium film by the thermal evaporation method;

[0021] 5. The cold end and hot end electrodes are prepared by the evaporation method.

Embodiment 2

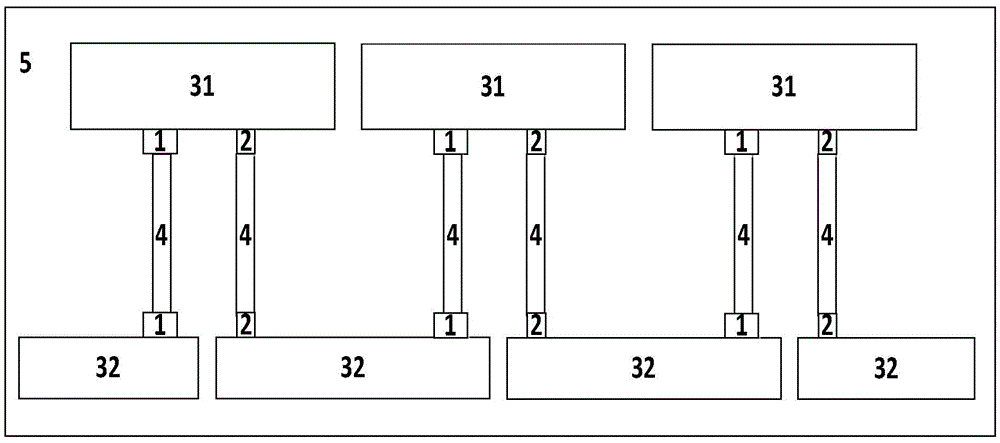

[0022] Example 2 (attached image 3 )

[0023] 1. Select polyimide film as flexible substrate

[0024] 2. Using thermal evaporation method to prepare two bismuth selenide thermoelectric films with a width of 5 mm and a length of 1 cm on the substrate, with an intermediate distance of 1 cm;

[0025] 3. Use the same method to prepare two antimony telluride thermoelectric films with a length of 5 mm and a length of 1 cm, with an intermediate distance of 1 cm;

[0026] 4. Prepare the copper film connected with the bismuth selenide film and the copper film connected with the antimony telluride film by the thermal evaporation method;

[0027] 5. The cold end and hot end electrodes are prepared by the evaporation method.

Embodiment 3

[0029] 1. Choose a quartz plate as the substrate;

[0030] 2. Using molecular beam epitaxy on the substrate to prepare two silicon germanium thermoelectric films with a width of 5 mm and a length of 1 cm, with an intermediate distance of 1 cm;

[0031] 3. The laser flash method is used to prepare two ferrosilicon thermoelectric films with a length of 5 mm and a length of 1 cm, with an intermediate distance of 1 cm;

[0032] 4. Prepare the copper film connected to the silicon-germanium film and the copper film connected to the ferrosilicon film by the thermal evaporation method;

[0033] 5. The cold end and hot end electrodes are prepared by the evaporation method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com